Quilt inner cotton carding device

A technology of carding and dust cage, which is applied in deburring devices, textiles and papermaking, fiber processing, etc. It can solve the problems of secondary pollution of finished products by tires and affect the air quality of production workshops, and achieve a high degree of automation and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The qualifiers such as front, back, left, and right used in this application are all based on the structure in the drawings or the actual use state.

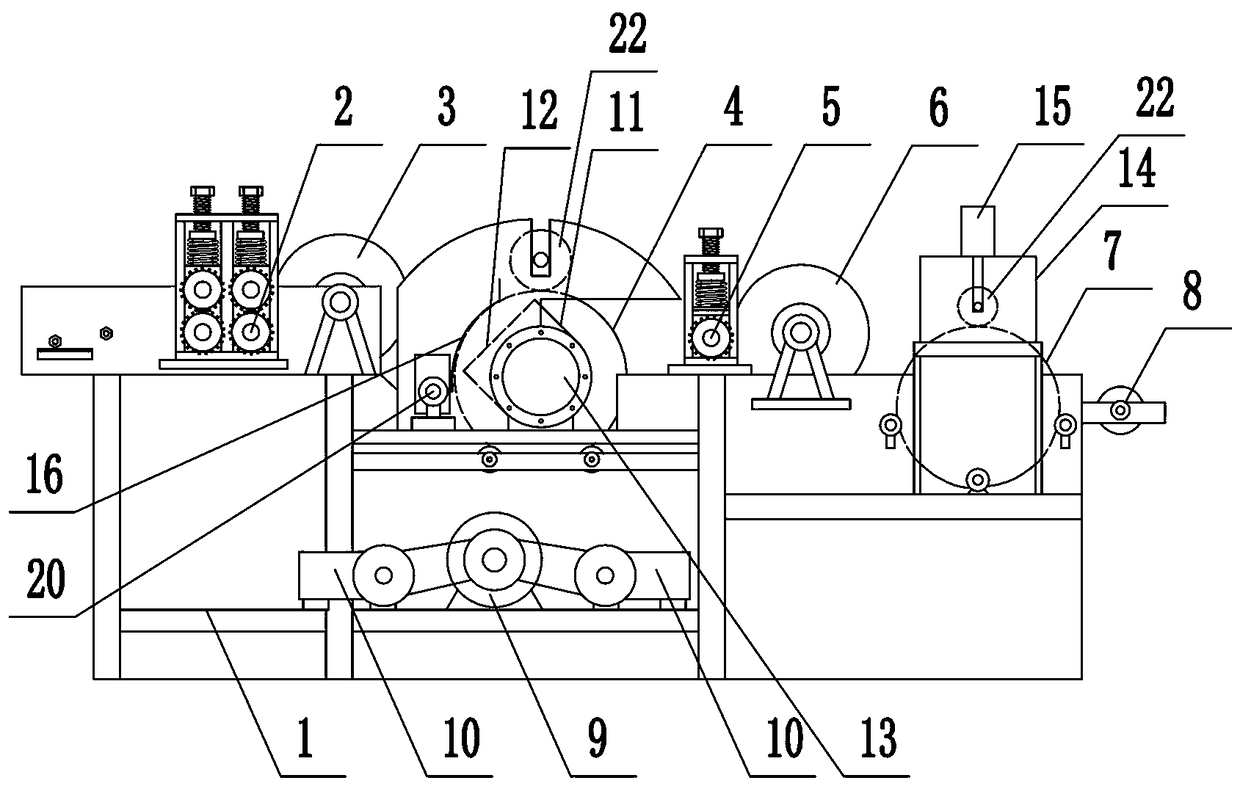

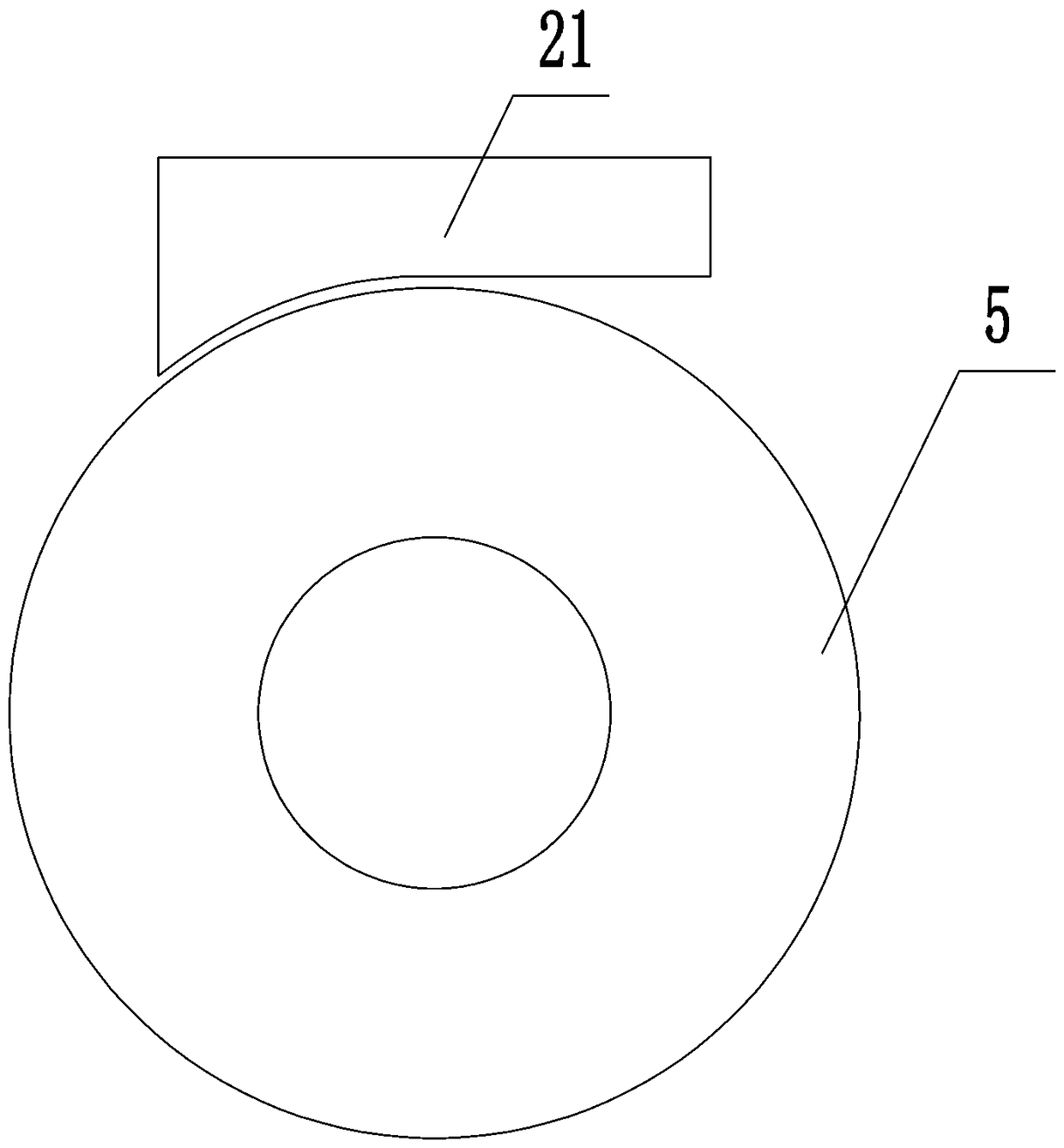

[0019] Such as figure 1 As shown, a quilt carding device disclosed in the present invention includes a frame 1 and a first cotton feed roller assembly 2, a first licker-in roller 3, a first dust cage 4, a first The second cotton roller assembly 5, the second licker-in roller 6, the second dust cage 7 and the first auxiliary roller 8, a power device is arranged on the frame 1, and the power device includes a motor 9 and two speed reducers 10 positioned on both sides of the motor, The first cotton-feeding roller assembly 2 is four cotton-feeding rollers, the two cotton-feeding rollers arranged up and down form a group, and a driven wheel is arranged on the end shaft of the two cotton-feeding rollers in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com