Ironing and fixing device for producing glass fiber woven mesh cloth

A glass fiber, fixing device technology, applied in textile and paper making, fabric surface trimming, cloth rack/dryer accessories, etc., can solve the problems of easy fatigue of workers, reduced product quality, sloppy ironing work, etc. The effect of novel structure, improved work efficiency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

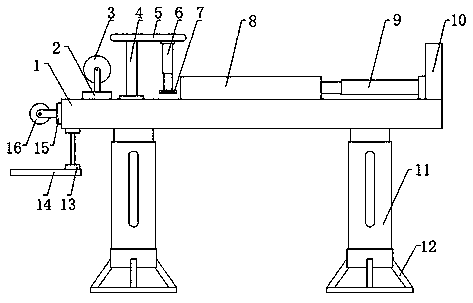

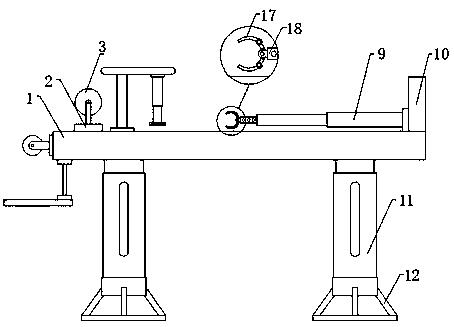

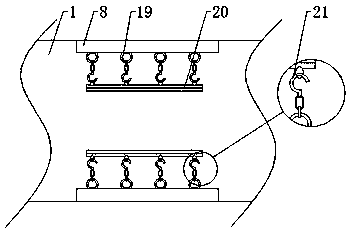

[0023] refer to Figure 1-4 , an ironing and fixing device for the production of glass fiber woven mesh cloth, comprising a workbench 1, one side of the bottom outer wall of the workbench 1 is fixed with a connecting column 13 by bolts, and the bottom outer wall of the connecting column 13 is fixed with a fixed Plate 14, the position of one side of the outer wall of the workbench 1 near both ends is fixed with a fixing seat 15 by bolts, and the same first roller 16 is inserted on the opposite side of the outer wall of the fixing seat 15, and the outer wall of the top of the workbench 1 The position close to the first roller 16 on one side is fixed with equidistant su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com