High wear resistant PU artificial leather and preparation technology thereof

A kind of artificial leather, high wear-resistant technology, applied in the field of artificial leather, can solve the problems of many residual solvents, large odor, large amount of solvent usage, etc., and achieve the effect of reducing the harm to the human body and the environment, good effect, and excellent odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

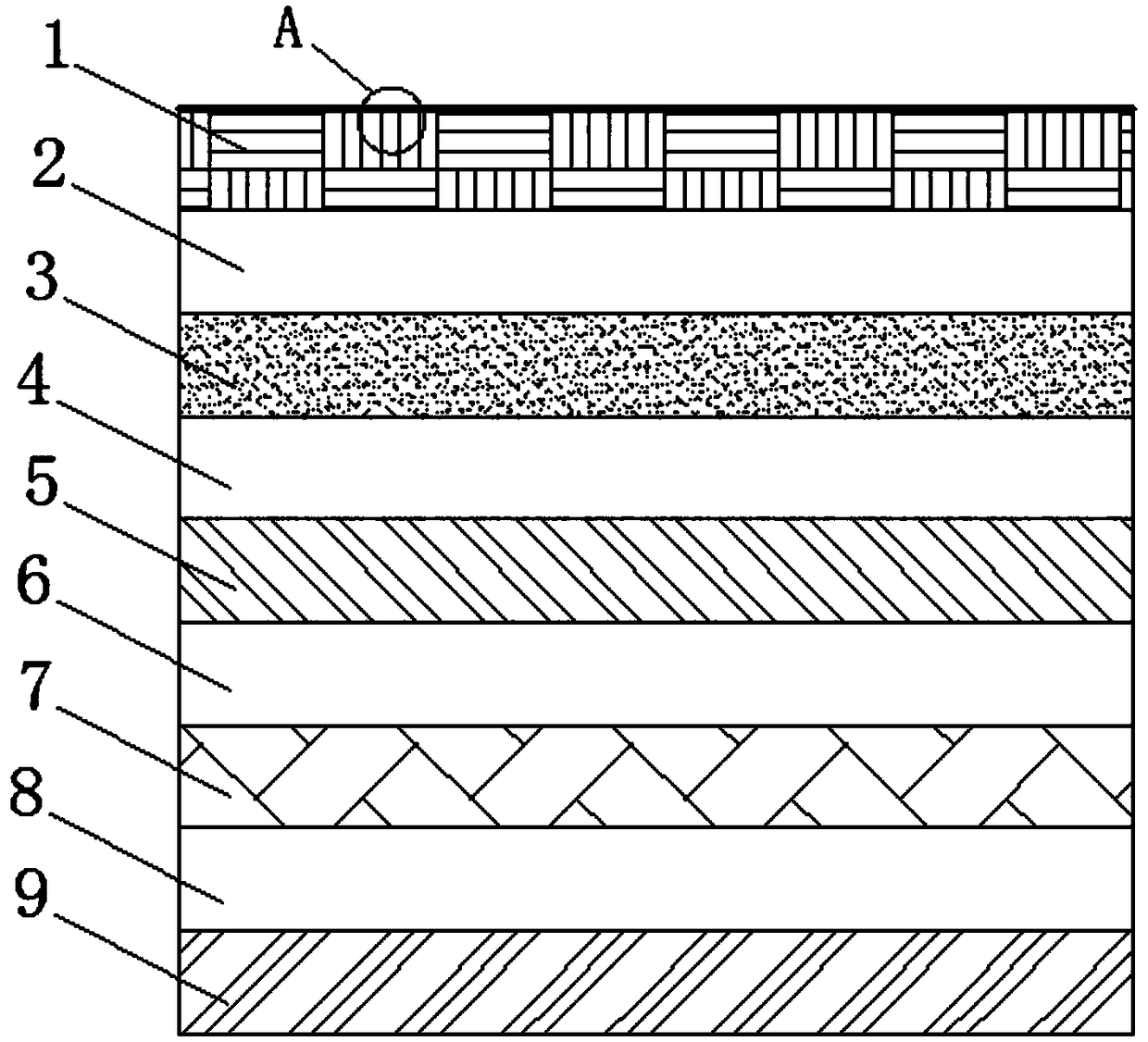

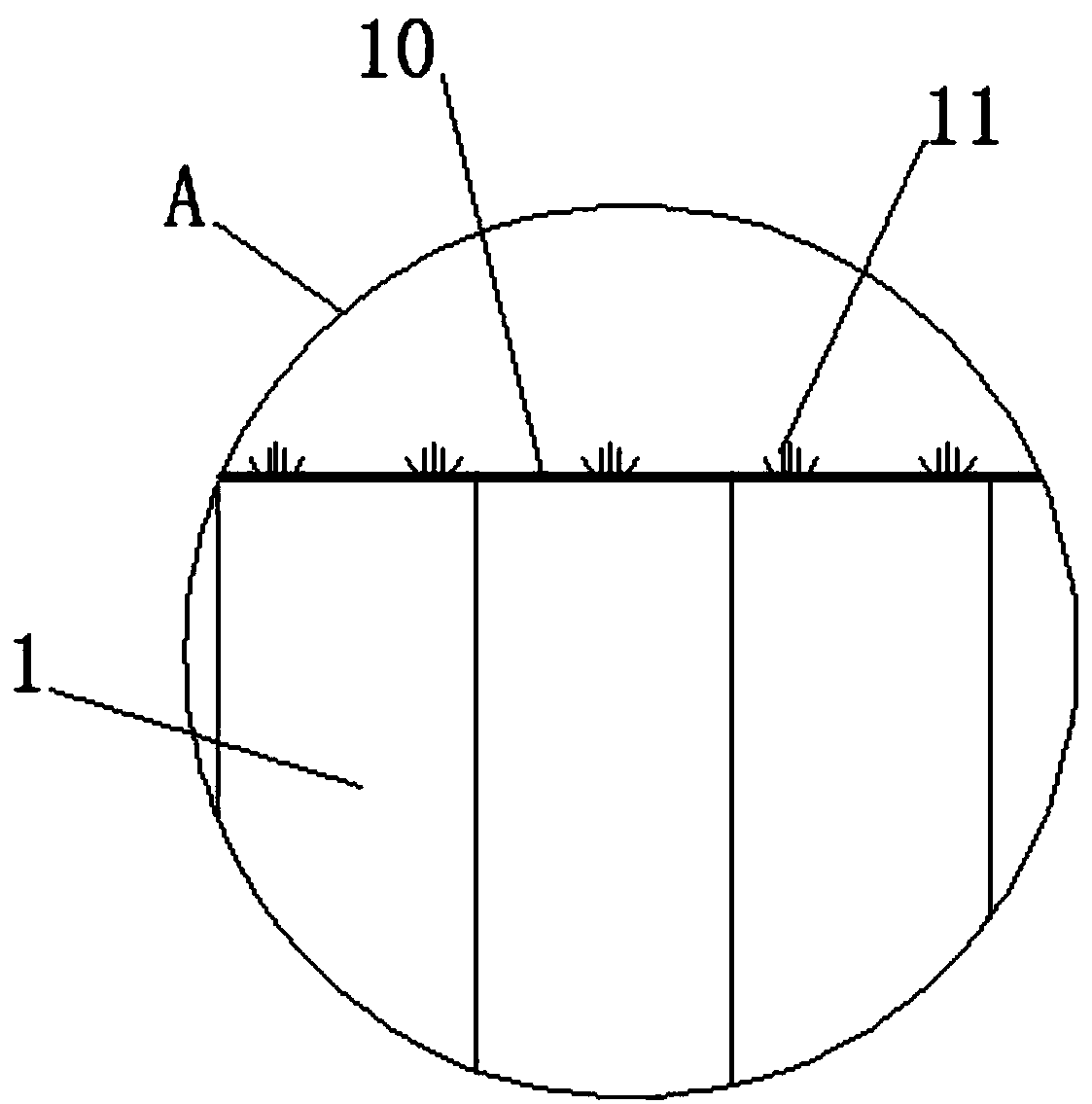

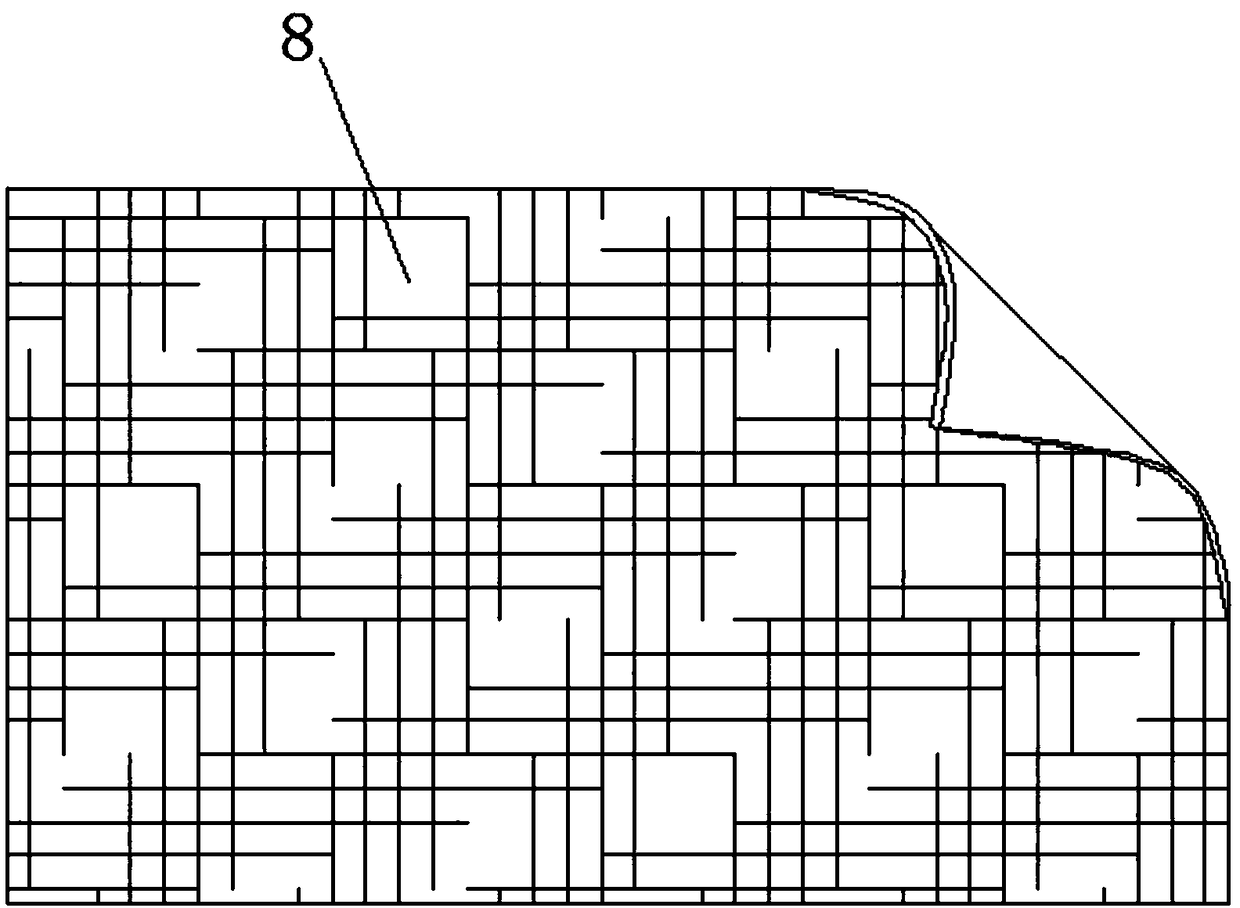

[0049] see figure 1 , a high wear-resistant PU artificial leather and its preparation process, comprising a main structure layer 6, the upper end of the main structure layer 6 is sequentially provided with a reinforcing wear-resistant layer 5, a wear-resistant layer 4, a surface layer 3, an anion layer 2 and a moisture-absorbing layer 1 The hygroscopic layer 1 and the anion layer 2 both use water-based polycarbonate, and protein material is added to the hygroscopic layer 1. After the water-based polycarbonate and the protein material are mixed, the hygroscopic layer 1 is endowed with a hygroscopic function, and the anion layer 2 Adding negative ion materials, water-based polycarbonate and negative ion materials are mixed, so that the negative ion layer 2 is endowed with the function of purifying the air. At the same time, the negative ion material in the negative ion layer 2 can eliminate free radicals, which has a good effect on human health. It can sterilize and deodorize. T...

Embodiment 2

[0054] A kind of preparation technology of high abrasion-resistant PU artificial leather described in embodiment 1, comprises the following steps:

[0055] The first step is to add protein raw materials into the water-based polycarbonate, and then mix the two to obtain the hygroscopic layer 1;

[0056] The second step is to add anion material to water-based polycarbonate, and then mix the two to obtain anion layer 2;

[0057] The third step, the surface layer 3 is treated with a water-based polycarbonate resin surface treatment agent;

[0058] The fourth step is to use polycarbonate resin and an environmentally friendly wear-resistant agent to eliminate air bubbles and improve the density through precision defoaming equipment to obtain a wear-resistant layer 4, thereby increasing wear resistance, and then setting a supplementary layer in the same way Strong wear-resistant layer 5;

[0059] The fifth step is to use a two-component polyether resin with a solid content of more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com