Form-variable stilling basin front end energy dissipation structure and energy dissipation method thereof

A stilling tank and pressure sensor technology, applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of low energy dissipation efficiency and high pressure of stilling tanks, improve atomization and reduce various pressures , the effect of stable water flow out of the pool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

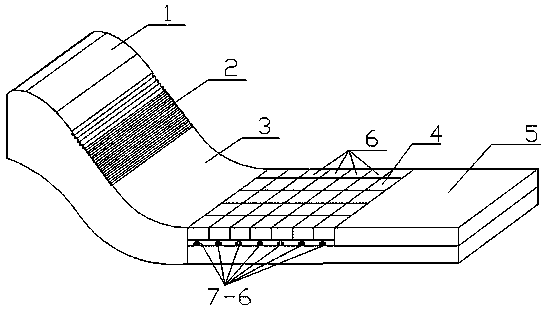

[0038] Embodiment 1: as figure 1 , 7 , 8 and 9, a modified form of stilling pool front end energy dissipation structure, including WES curve section 1, WES step straight section 2, WES anti-arc section 3, stilling pool front end 4, stilling pool rear end 5, Pressure sensor, controller, auxiliary hydraulic jacking device, main hydraulic jacking device, WES curve section 1 is connected with WES straight section 2, WES straight section 2 is connected with WES anti-arc section 3, the tail of WES anti-arc section 3 is connected with the disappearing The front end 4 of the stilling pool is connected, and the front end 4 of the stilling pool is connected with the rear end 5 of the stilling pool. The front end 4 of the stilling pool is evenly divided into several blocks 6, and each block 6 is equipped with an auxiliary hydraulic jack Lifting device, auxiliary hydraulic jacking device includes auxiliary hydraulic cylinder 7-5, auxiliary lifting column 7-6, auxiliary hydraulic cylinder...

Embodiment 2

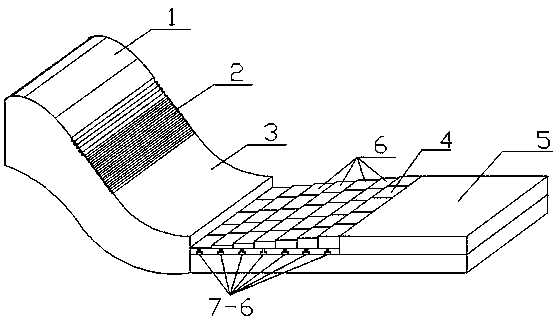

[0047] Embodiment 2: as figure 2 As shown, the structure of this embodiment is the same as that of Embodiment 1, the difference is that the first row of blocks 6 at the front end 4 of the stilling pool all descends as a whole, and the descending height is the same and the largest, and every subsequent row descends, and the descending height Although it is consistent but gradually decreases, a drop sill with a certain height difference can be formed between the WES anti-arc section 3 and the front end 4 of the stilling pool, and the front end 4 of the stilling pool can be formed as a whole to form a bottom slope of the stilling pool i>0 This form can increase the concentration of aeration in the process of underflow energy dissipation, and strengthen the tumbling of the water flow at the connection, so as to achieve the purpose of energy dissipation.

Embodiment 3

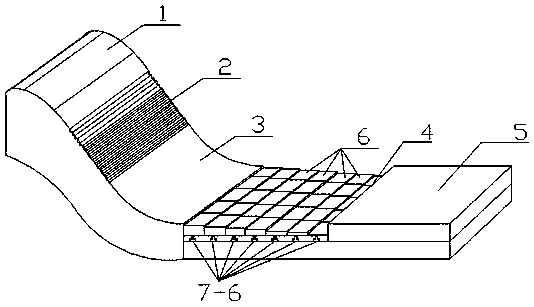

[0048] Embodiment 3: as image 3 As shown, the structure of this embodiment is the same as that of Embodiment 1, the difference is that the relative height H of the first row of blocks 6 at the front end 4 of the stilling pool does not change, and the overall height H of each row of blocks 6 afterward All descend, the relative height H of the same row of blocks is equal, and the height of the blocks 6 of different rows gradually increases as they go further, so that the front end 4 of the stilling pool can form a bottom slope of the stilling pool as a whole i< 0, so that the discharged water can continuously fall at the front end 4 of the stilling basin, and more sufficient collision and mixing can be carried out at the position between the front end 4 of the stilling basin and the rear end 5 of the stilling basin It is more conducive to the energy dissipation of the water flow in the stilling pool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com