Automated flattening machine for wall surfaces and floors

A wall, floor and flat machine technology, which is applied in the direction of construction and building structure, can solve the problems of inconvenient construction quality control, high labor intensity, and cracking of the mortar layer, so as to reduce the working time of workers, reduce labor intensity, and enhance Ergonomic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

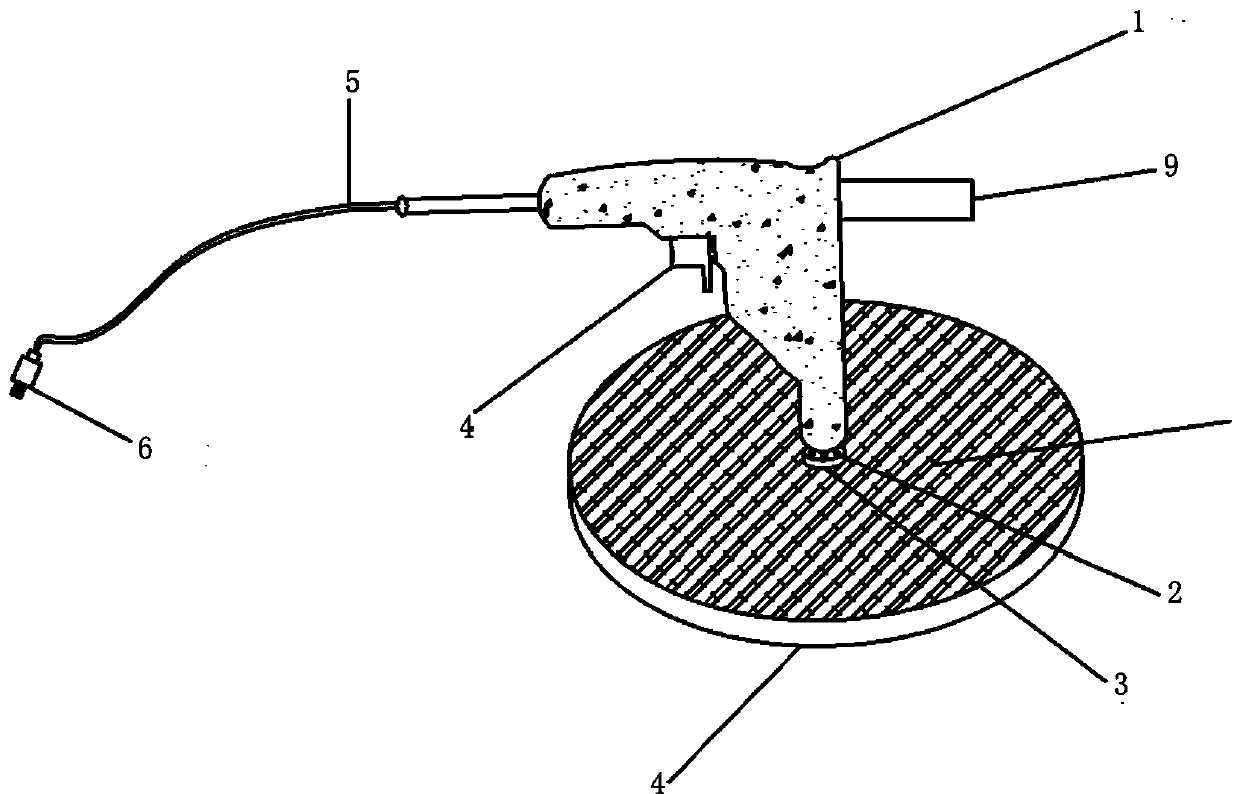

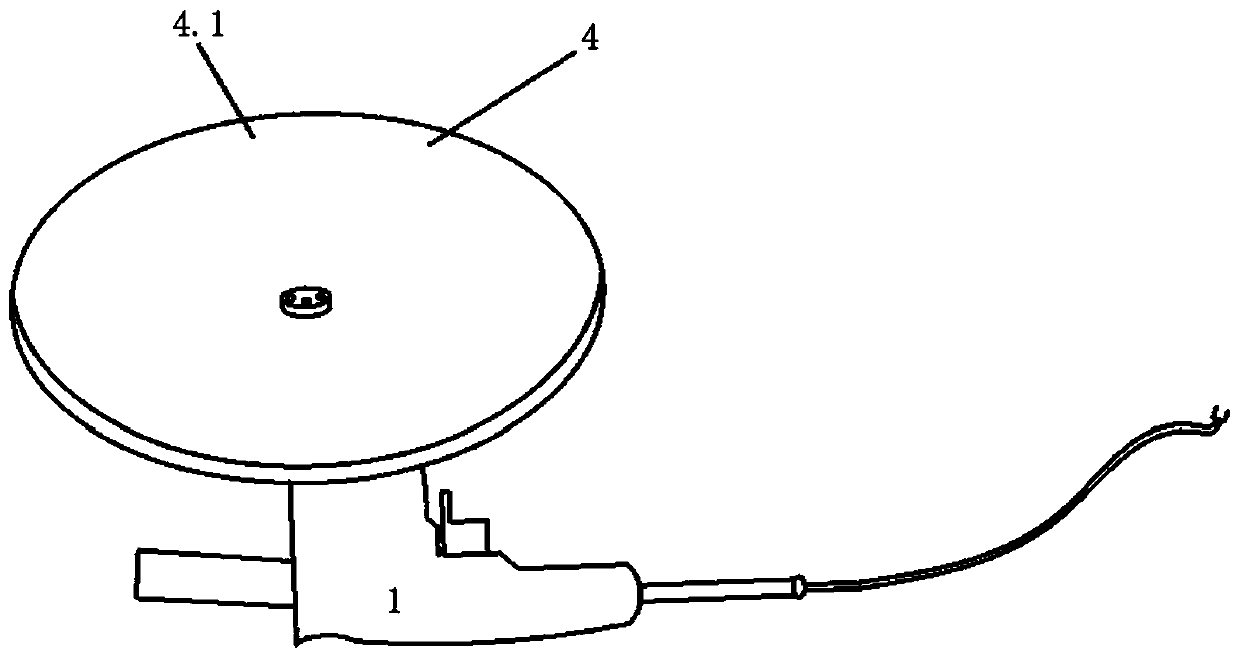

[0023] like Figure 1~Figure 4 As shown, an automatic wall and floor leveling machine includes an electric rotating mechanism 1 . The electric rotating mechanism 1 is provided with a rotating screw 2, and the rotating screw 2 is fixedly installed with a honeycomb circular rubber plate 4 through a gasket 3;

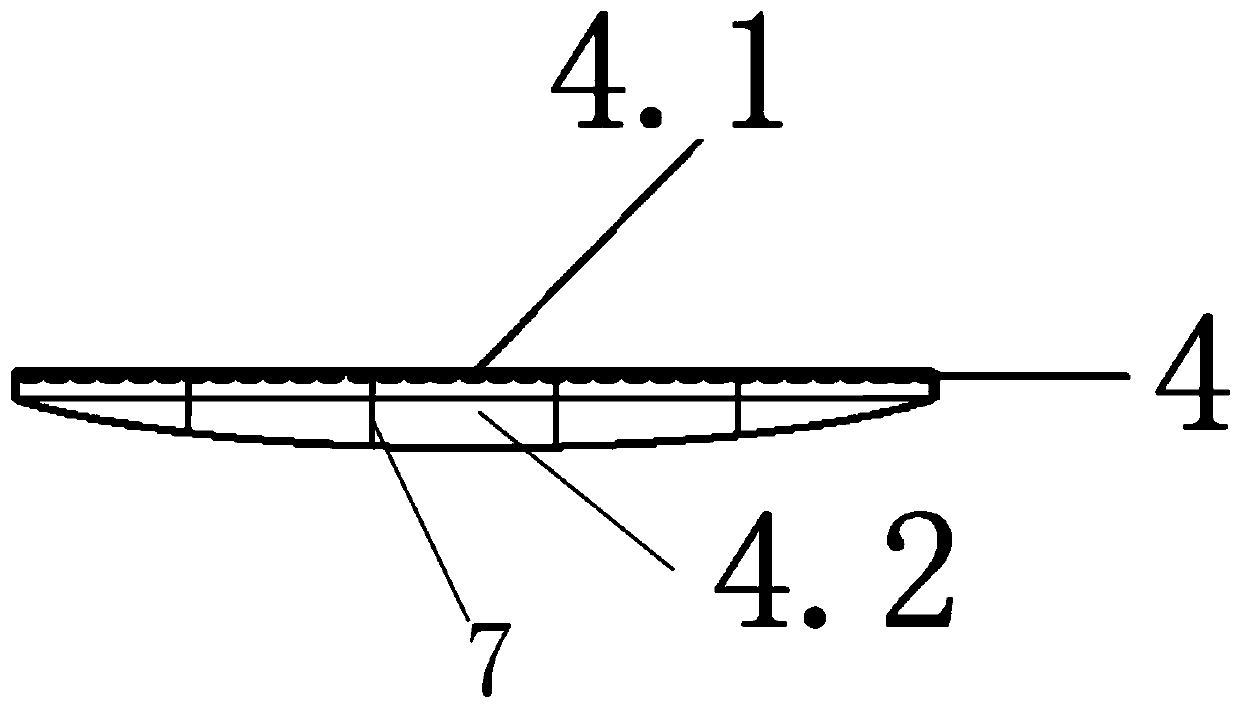

[0024] The bottom surface 4.1 of the honeycomb circular rubber sheet 4 is a horizontal plane, and the top surface 4.2 is an arc-shaped surface;

[0025] A reinforcing rib 7 is fixed on the top surface of the honeycomb circular rubber sheet 4 .

[0026] The electric rotating mechanism 1 is refitted from an electric drill in the prior art. The electric rotating mechanism 1 includes a stepless variable speed motor connected to a rotating screw 2 on which fastening nuts are arranged.

[0027] The electric rotating mechanism 1 is provided with a handle 9 and a switch 4 , and the tail of the electric rotating mechanism 1 is connected to a plug 6 through an electric wire 5 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com