Groove tooth-shape structure for drafting lower roller

A groove and tooth shape technology, applied in drafting equipment, textiles, papermaking, spinning machines, etc., can solve the problem of affecting the uniformity of the evenness and the quality of the finished product, reducing the contact area between the working surface of the groove and the top roller, Affects the uniformity of evenness and finished product quality, and achieves the effect of improving yarn holding force, reducing processing procedures and reducing mechanical waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

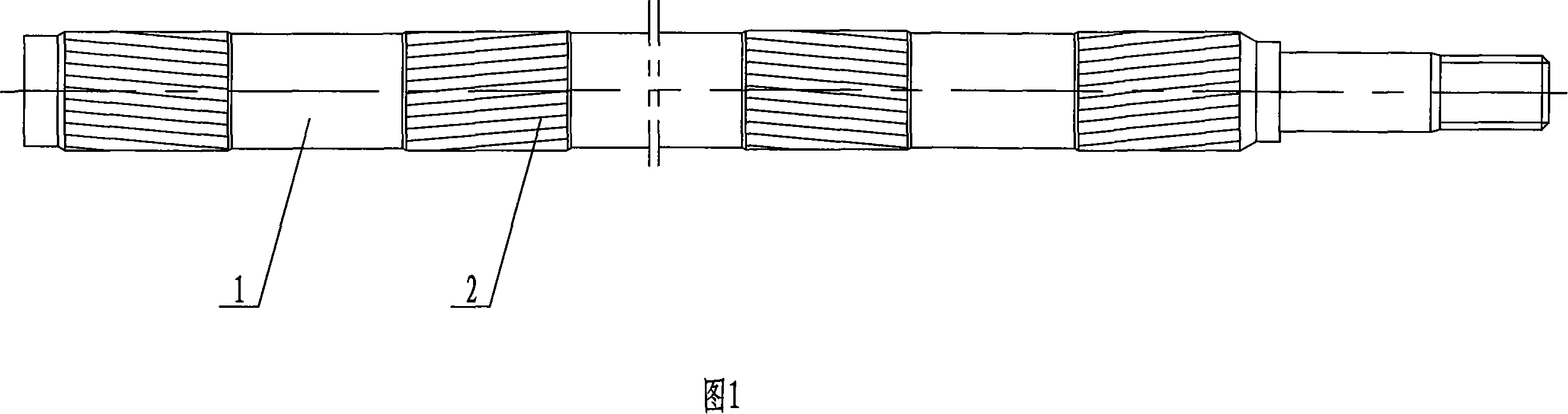

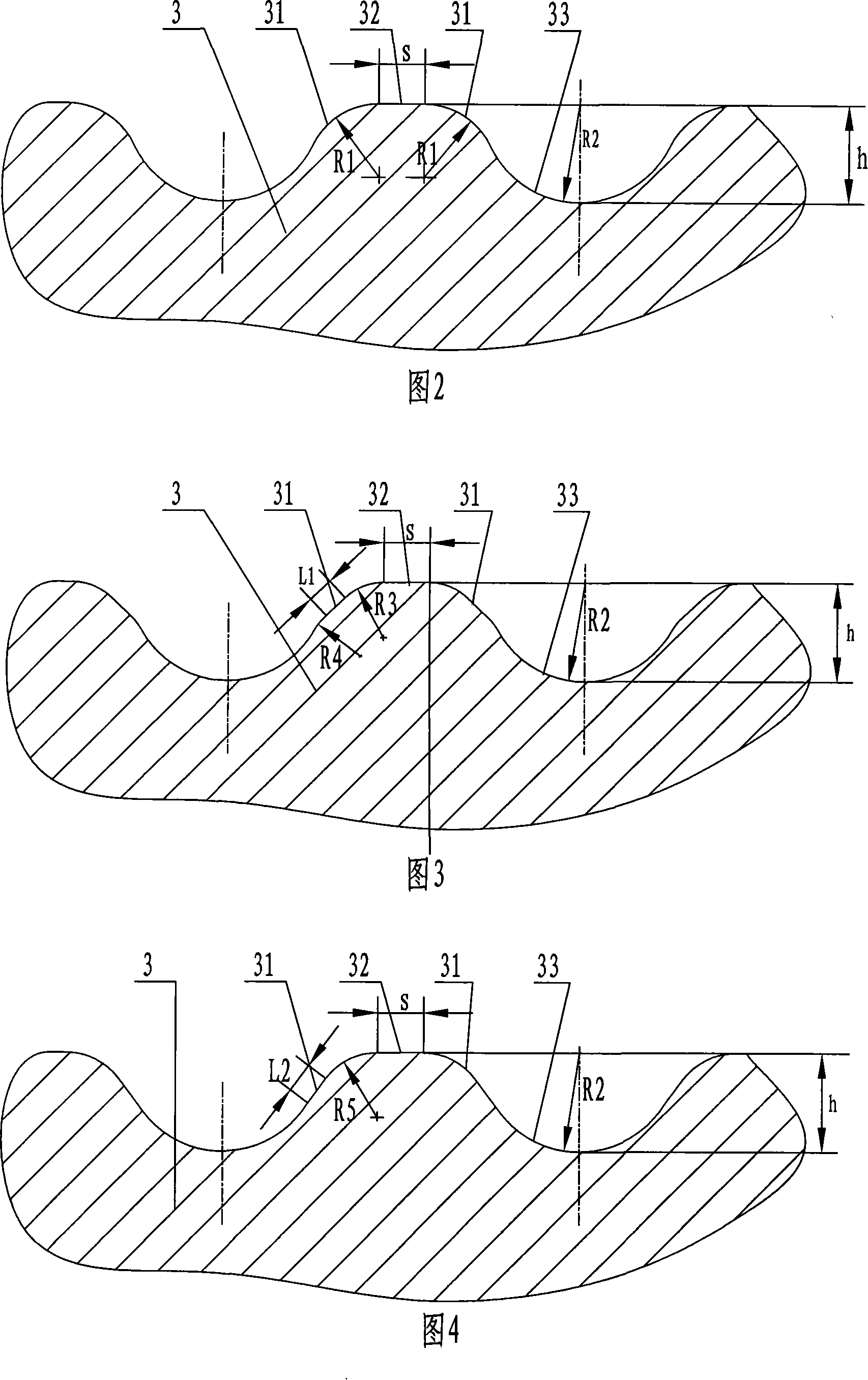

[0016] The groove tooth structure of the drafting bottom roller of the present invention is shown in Fig. 1, and the drafting bottom roller includes an optical axis 1, a groove working surface 2 and a guide hole arranged at intervals between the optical axes 1, and the groove The groove tooth profile 3 on the working surface 2 can be a helical tooth profile or a straight tooth profile. The groove tooth shape 3 is shown in Figure 2, and its outer contour is composed of the addendum arc length 31 formed by the outer circle of the roller, the curve 32 smoothly transitioned to the two ends of the addendum arc length 31, and the tooth tangent to the curve 32. Bottom arc length 33, the curve 32 is the transition arc length inscribed with the addendum arc length 31, and the radius R2 of the tooth bottom arc length 33 ≥ the radius R1 of the excess arc length, the chord length S of the addendum arc length is 0.1mm~0.5mm, the radius R1 of the transition arc length is 0.25mm~0.4mm, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chord length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com