Solid adsorbent tube pretreatment automatic sample preparation instrument

A solid sorbent, automatic sample preparation technology, applied in sampling, instruments, scientific instruments, etc., can solve the problems of inaccurate quantification of volatile substances, easy injury of solid sorbent tubes, and long time-consuming dumping process, so as to avoid personnel problems. Injury, occupational hazard reduction, time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

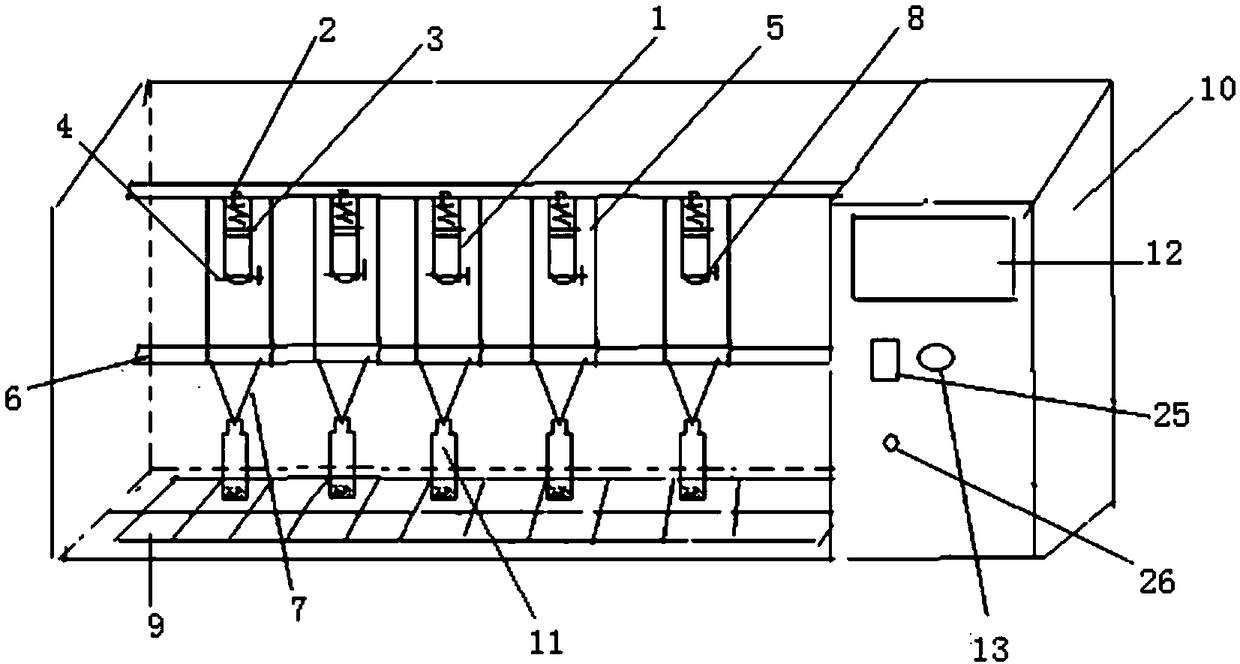

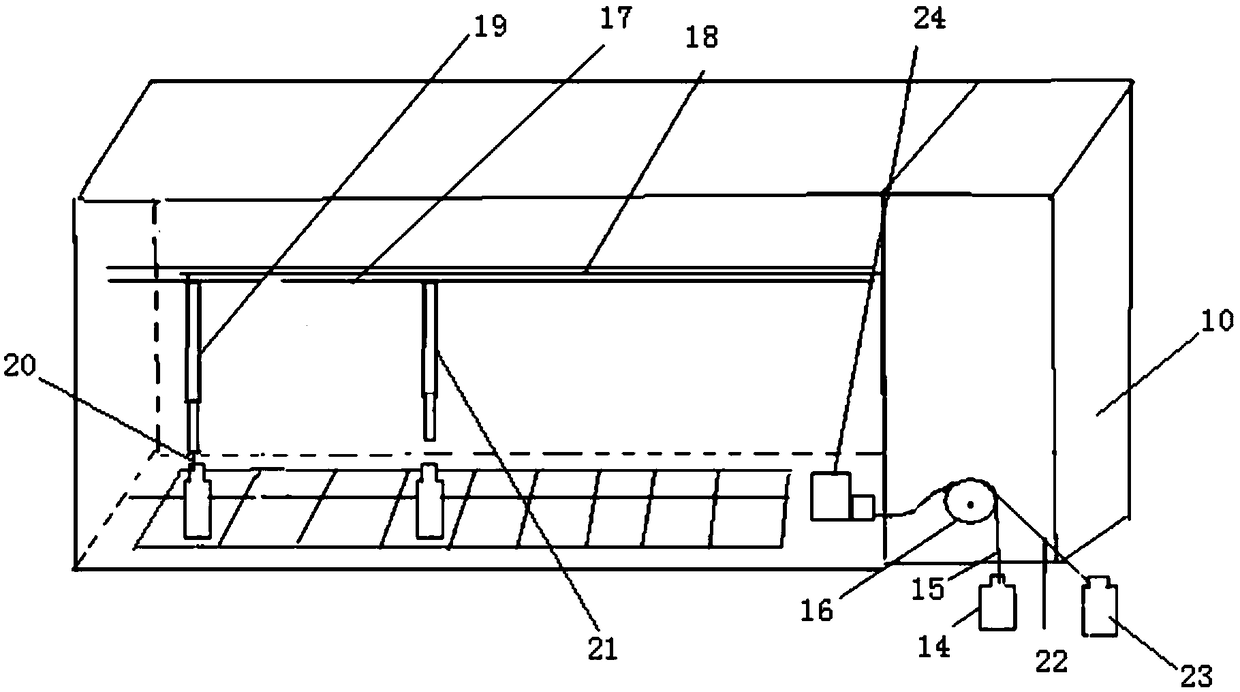

[0024] As shown in the figure, the automatic sample preparation instrument for solid adsorbent tube pretreatment includes a box body, a tube body cutting and dumping device, an automatic sample adding capping device and a control box 10, and the tube body cutting and dumping device is located on one side of the box body; The automatic sample adding and capping device is located on the other side of the box; the control box 10 is located at one end outside the box, and the control box 10 is electrically connected with the tube body cutting and pouring device and the automatic sample adding and capping device.

[0025] The pipe body cutting and dumping device comprises a pipe body jacket 1, a spring 2, a rubber gasket 3, a fixing bolt 4, a protective cover 5, a screen 6, a funnel 7, a ring knife 8 and an induction sample tray 9, and the pipe body The jacket 1 is fixed on the inner top of the box, the inner top of the pipe body jacket 1 is fixedly installed with a spring 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com