Walnut kernel peeling device

A peeling device and technology for walnut kernels, which are applied in the fields of shelling, pod removal, food science, etc., can solve problems such as increasing costs, affecting the ecological environment, and detrimental to the long-term development of enterprises, saving production costs, saving manpower and material resources, and reducing peeling. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

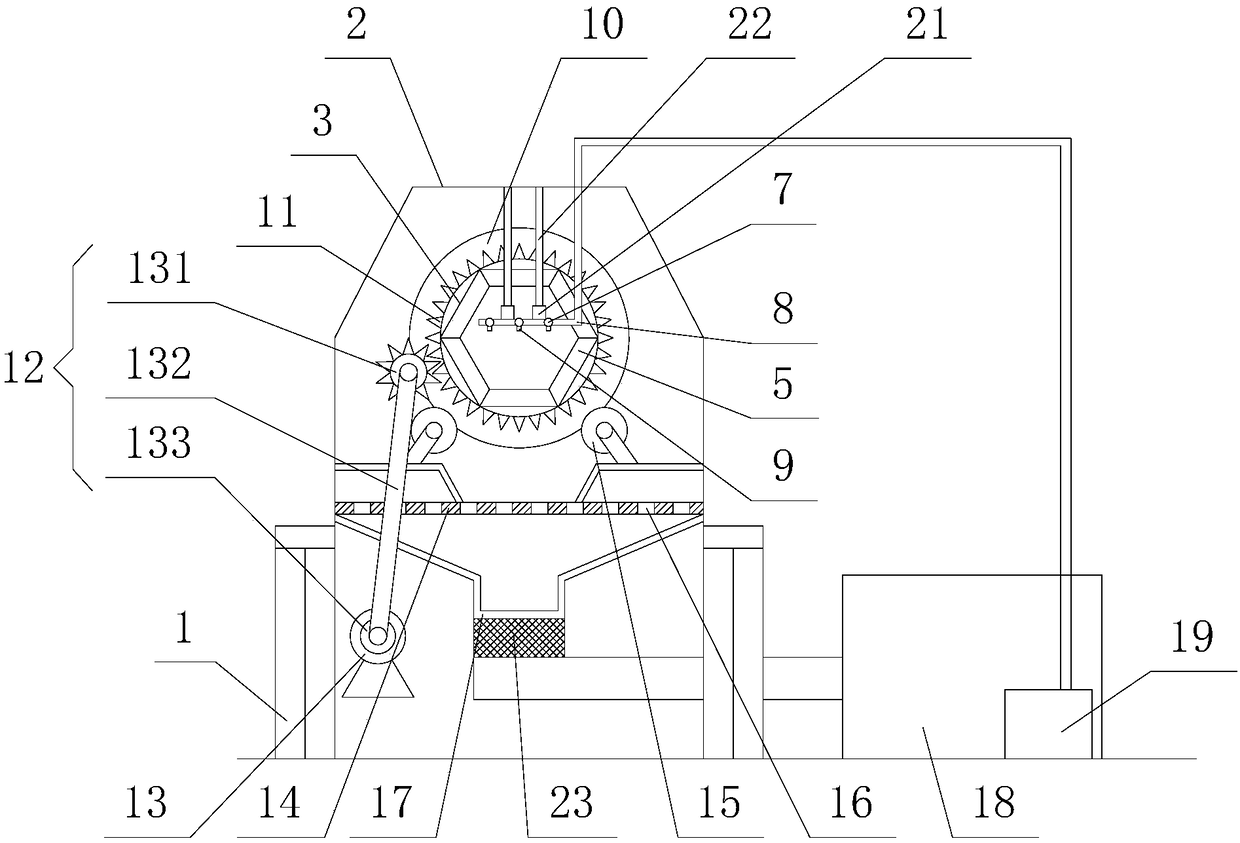

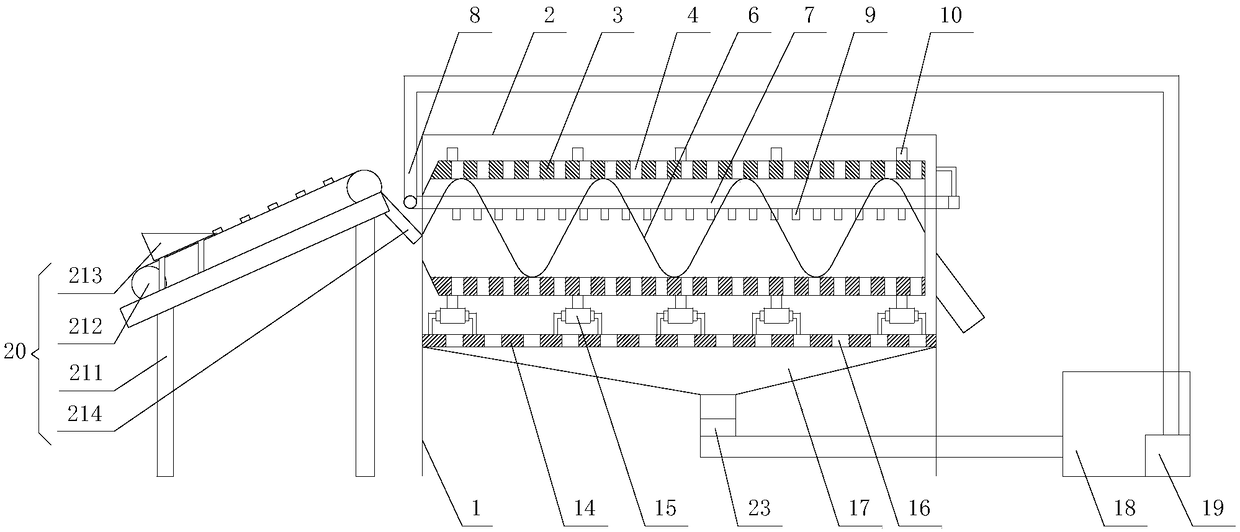

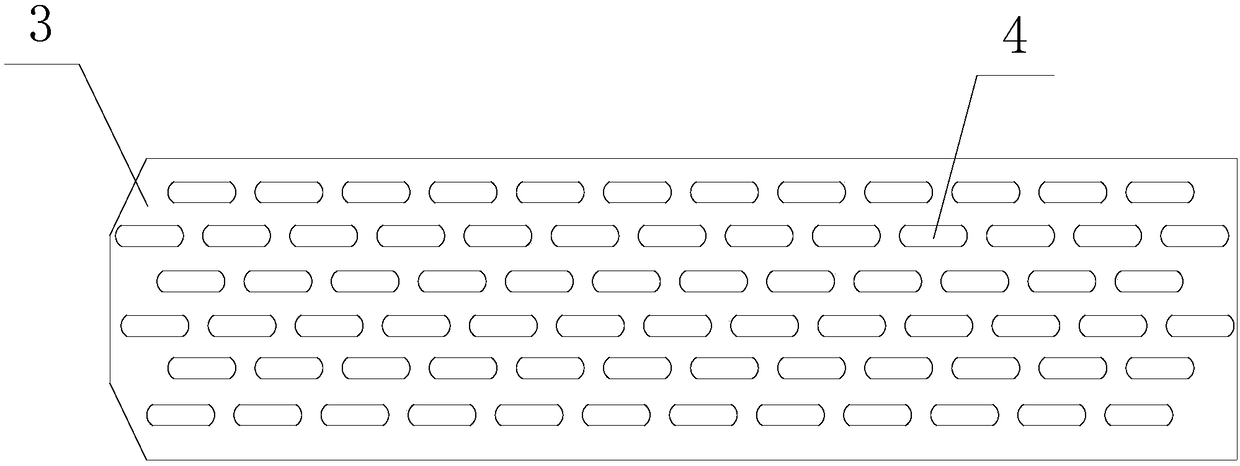

[0023] like figure 1 and figure 2 As shown, the walnut kernel peeling device provided by the present embodiment comprises a frame 1, a casing 2 and a feeding lifting mechanism 20, the casing 2 is provided with a horizontal cylinder 3, and one end of the cylinder 3 is a feeding end, and the other One end is a discharge end, and the feeding lifting mechanism 20 includes a support frame 211, a conveyor belt 212, a feeding baffle 213 and a feeding plate 214, and the surface of the conveyor belt 212 is evenly spaced with anti-skid ribs, and the conveying Belt 212 is obliquely installed on the support frame 211, and the low end of conveyor belt 212 is provided with feeding baffle 213, and the top end of conveyor belt 212 is equipped with blanking plate 214, and blanking plate 214 is obliquely arranged, and the bottom of blanking plate 214 One end and the support frame 211 are fixed at the top of the conveyor belt 212, and the other end is located at the feeding end of the drum 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com