Method for preparing all-natural enzyme fermented black hair dye

A technology of black hair dye and natural enzyme, which can be applied to medical preparations containing active ingredients, hair care, pharmaceutical formulations, etc., can solve problems such as lack of pigment extraction technology, and achieve the effect of overcoming difficulties in extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

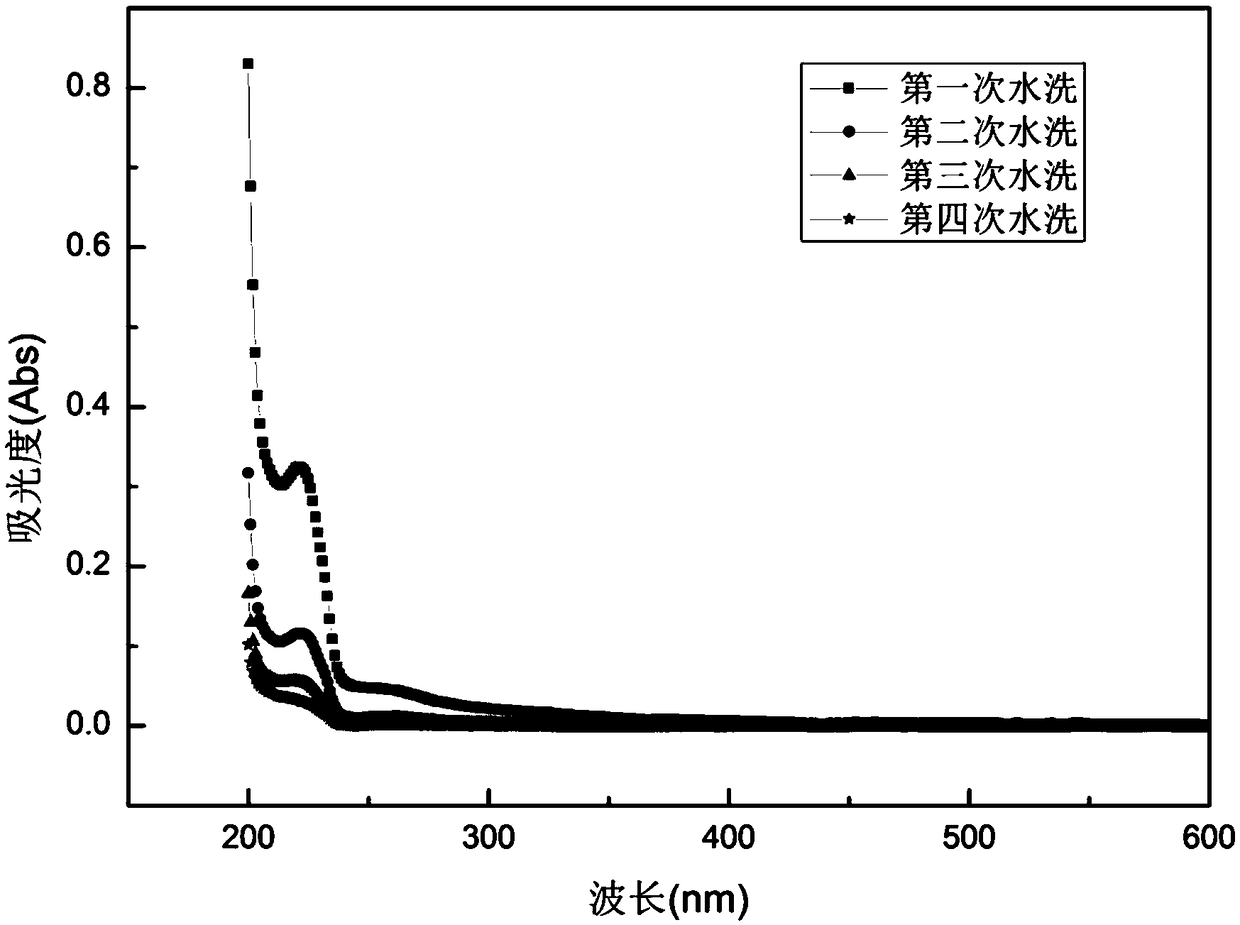

Image

Examples

Embodiment 1

[0040] Step 1, using black soybeans to prepare tyrosinase liquid;

[0041] Mix black soybeans with a phosphate buffer solution with a pH of 7, the ratio of black soybeans to phosphate buffer solution is 10g:20ml, and then ultrasonically extract at 25°C for 2.5 hours to obtain an extract;

[0042] After centrifuging the extract at 3000r for 4min, take the supernatant, add ammonium sulfate with a mass concentration of 55% in the supernatant and let it stand for 3h, then continue to centrifuge at 4000r for 10min and pour off the supernatant, then add pH The phosphate buffer solution of 7 was shaken to obtain the tyrosinase solution;

[0043] Step 2, preparation of tyramide substrate solution

[0044] Dissolving tyramine in a phosphate buffer solution with a pH of 7 to prepare a tyramine substrate solution with a concentration of 0.01 g / mL;

[0045] Step 3, preparing the melanin precursor in the biological fermentation system

[0046] Mix the tyrosinase solution prepared in ste...

Embodiment 2

[0049] Step 1, using black soybeans to prepare tyrosinase liquid;

[0050] Mix black soybeans with phosphate buffer solution with a pH of 7.5, the ratio of black soybeans to phosphate buffer solution is 10g: 40ml, and then ultrasonically extract at 30°C for 3 hours to obtain an extract;

[0051] After centrifuging the extract at 3000r for 5min, take the supernatant, add ammonium sulfate with a mass concentration of 55% in the supernatant and let it stand for 3h, then continue to centrifuge at 4000r for 10min and pour off the supernatant, then add pH The phosphate buffer solution of 7.5 is shaken to obtain the tyrosinase solution;

[0052] Step 2, preparation of tyramide substrate solution

[0053] Dissolving tyramine in a phosphate buffer solution with a pH of 7.5 to prepare a tyramine substrate solution with a concentration of 0.03 g / mL;

[0054] Step 3, preparing the melanin precursor in the biological fermentation system

[0055] The tyrosinase solution prepared in step ...

Embodiment 3

[0058] Step 1, using black soybeans to prepare tyrosinase liquid;

[0059] Mix black soybeans with a phosphate buffer solution with a pH of 8, the ratio of black soybeans to phosphate buffer solution is 10g:50ml, and then ultrasonically extract at 40°C for 3.5h to obtain an extract;

[0060] After centrifuging the extract at 3000r for 6min, take the supernatant, add ammonium sulfate with a mass concentration of 55% to the supernatant and let it stand for 3h, then continue to centrifuge at 4000r for 10min and pour off the supernatant, then add pH 8 phosphate buffer shocks to obtain tyrosinase solution;

[0061] Step 2, preparation of tyramide substrate solution

[0062] Dissolving tyramine in a phosphate buffer solution with a pH of 8 to prepare a tyramine substrate solution with a concentration of 0.05 g / mL;

[0063] Step 3, preparing the melanin precursor in the biological fermentation system

[0064] The tyrosinase solution prepared in step 1 and the tyrosinase substrate so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com