Chaplet for engine cylinder block casting, application process of chaplet and combination core with chaplet

A technology for engine cylinder blocks and core supports, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of high heat required for fusion, easy cracks, and poor fusion quality, so as to reduce heat, avoid cracks, The effect of high fusion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

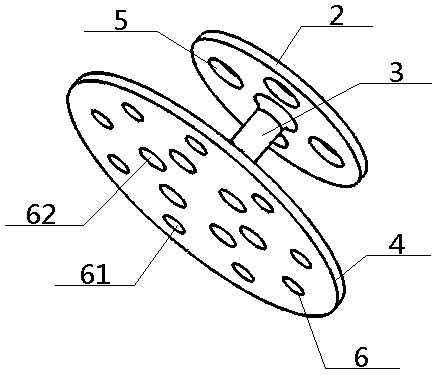

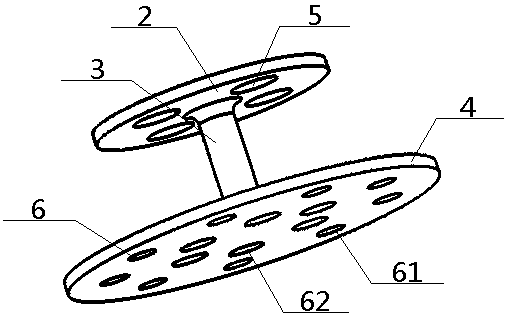

[0052] see Figure 1 to Figure 6 , a core support for engine cylinder casting, including an upper support seat 2, a middle connecting rod 3 and a lower support seat 4, the middle part of the bottom surface of the upper support seat 2 passes through the top surface of the middle connecting rod 3 and the lower support seat 4 The middle part is connected, the upper support base 2 is provided with a plurality of through-through upper fluxing holes 5, and the lower support base 4 is provided with a plurality of through-through lower fluxing holes 6; the upper support base 2, The melting points of the materials used for the middle connecting rod 3 and the lower support seat 4 are all lower than the temperature of the molten iron injected during casting filling. Preferably, the upper flux holes 5 are evenly arranged around the junction of the upper support seat 2 and the middle connecting rod 3 , and the lower flux holes 6 are evenly arranged around the junction of the lower support ...

Embodiment 2

[0056] Basic content is the same as embodiment 1, the difference is:

[0057] The number of the upper fluxing holes 5 is four, and they are evenly arranged along the same circumference; the lower fluxing holes 6 include nine lower outer fluxing holes 61 and six lower inner fluxing holes 62, and all the lower outer fluxing holes 62 The melting holes 61 are evenly arranged along the same circumference, all the lower inner fluxing holes 62 are evenly arranged along the same circumference, the radius of the circumference along the lower outer fluxing holes 61 is greater than the radius of the circumference along the lower inner fluxing holes 62, and the lower outer fluxing holes The circumference along the hole 61 and the circumference along the lower inner fluxing hole 62 are concentric circles.

Embodiment 3

[0059] Basic content is the same as embodiment 1, the difference is:

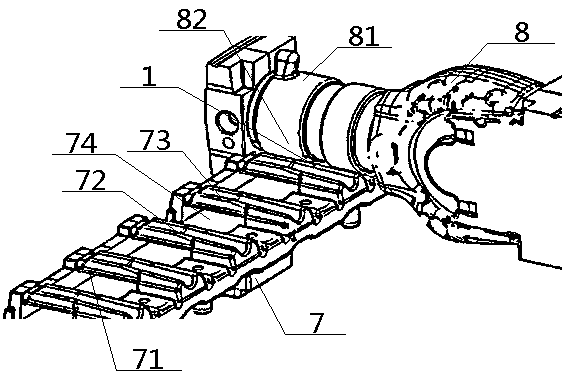

[0060] The lower support base 4 placed on the top surface of the lower tank water jacket core 7 means that the lower support base 4 is embedded in the lower support groove 75 provided on the top surface of the lower tank water jacket core 7 .

[0061] The contact between the upper support base 2 and the bottom side circumference 82 of the core head 81 means that the top surface of the upper support base 2 is in contact with the upper support point 83 provided on the bottom side circumference 82 of the core head 81 in the round rod core 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com