Lathe boring device for machining piston rod end opening or lug ring

A piston rod end and lathe technology, which is applied in boring/drilling devices, metal processing equipment, drilling/drilling equipment, etc., can solve the problems that lathes cannot perform boring operations, reduce the purchase cost of special equipment, and reduce production cost, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

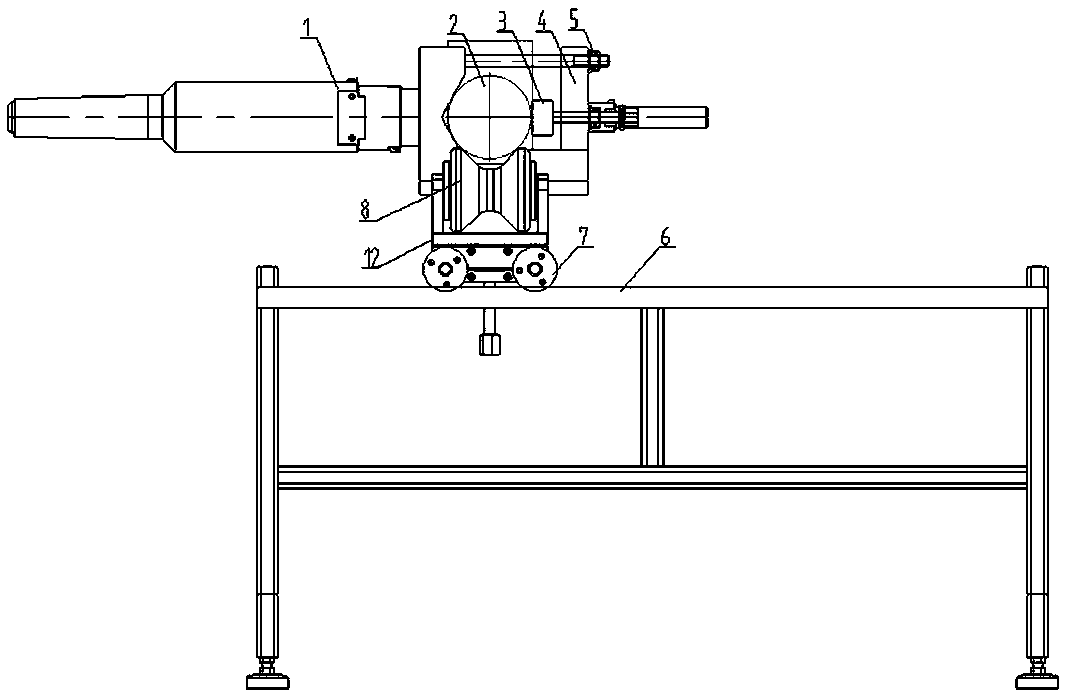

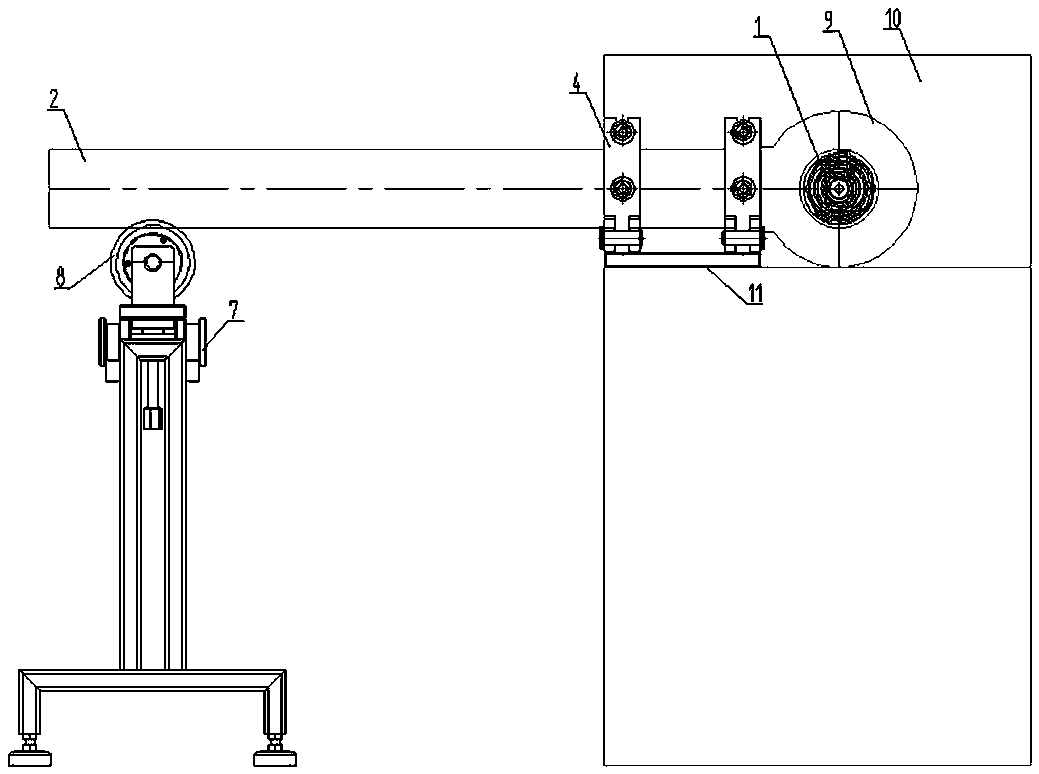

[0013] Refer to attached Figure 1-2 , the present invention belongs to a lathe accessory device, which is set independently from the lathe body 10. It includes a track support 6 set on one side of the lathe, and two tracks are fixed on the upper part of the track support. The follower trolley 12 is placed on the track through rollers 7 On, a supporting wheel 8 is fixed on the upper supporting plate of the trolley. The piston rod clamp 4 is fixed on the feed pallet 11 of the lathe body, and the boring tool 1 is fixed on the cutting tool chuck of the lathe. The boring tool 1 is designed as a stepped structure, and the fixed position of the boring tool is designed according to the feed length corresponding to the cutting thickness.

[0014] During work, the track support 6 is moved to the design position on one side of the lathe body 10, the piston rod clamp 4 is fixed on the lathe feed pallet 11, and the boring tool 1 is fixed on the lathe cutting tool chuck. The workpiece 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com