Multifunctional rotary drilling rig

A rotary drilling rig, multi-functional technology, applied in the direction of drilling tools, drilling equipment, earth drilling and mining, etc., can solve the problems of single construction, high cost of rotary drilling rig, failure to realize CFG drilling rig construction, soil squeezing pile machine construction, etc. , to achieve the effect of saving purchase cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

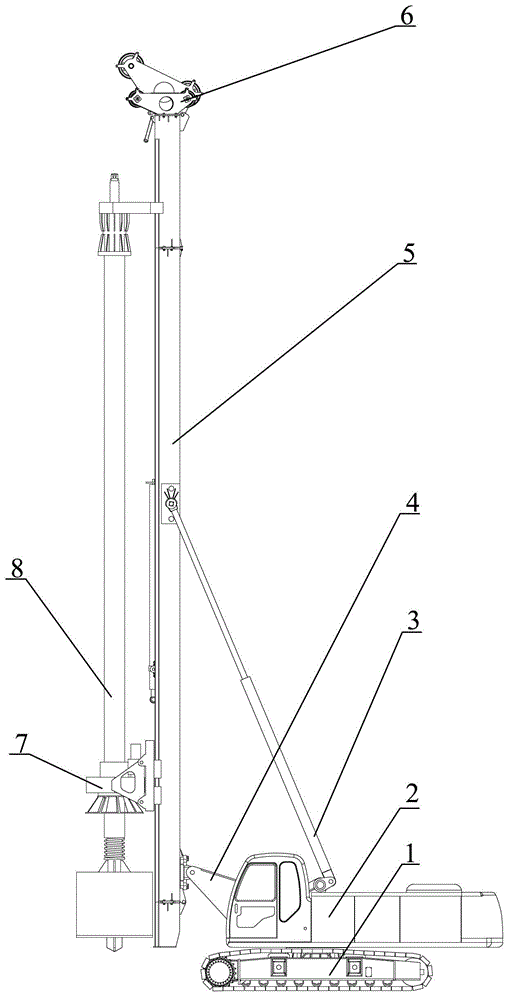

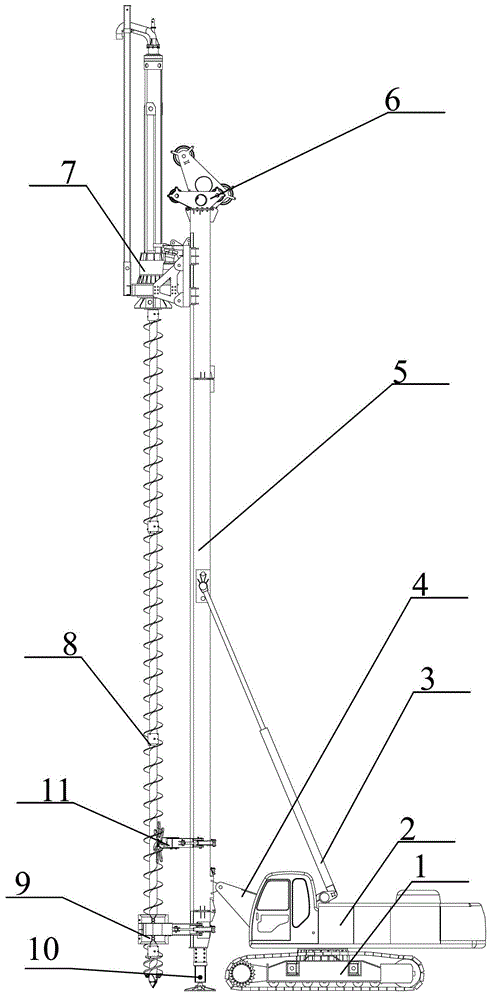

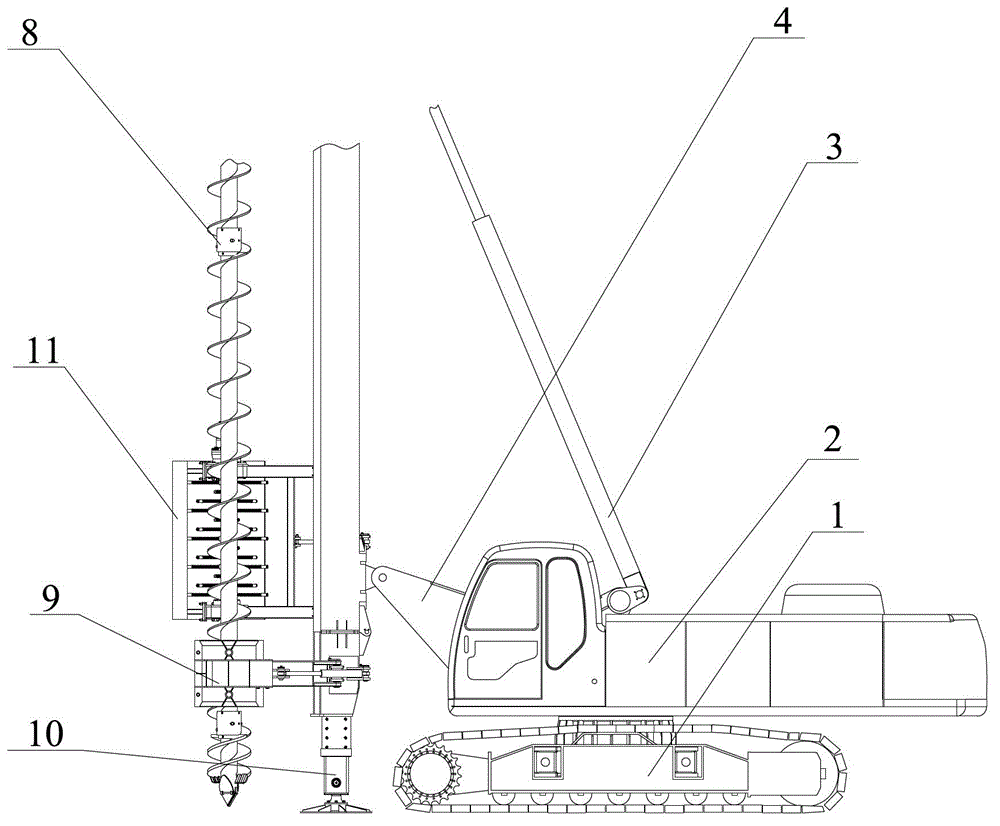

[0026] Such as Figure 1-3 The multifunctional rotary drilling rig shown includes a chassis 1, an upper car 2 installed on the chassis 1, a diagonal bracing cylinder 3 installed on the upper car 2, and a mast 5 connected to the hoisting box 4 and the oblique Support oil cylinder 3, hoist box body 4 is fixed on the front end of boarding car 2, and the end of mast 5 is equipped with straightening device 9, and the top of straightening device 9 is provided with soil clearer 11, and soil clearer 11 is also arranged on mast 5. Legs 10 are installed at the bottom of the mast 5 . The head pulley frame 6 with adjustable orientation is installed on the mast 5 top, and the head pulley frame 6 connects the power head 7. The power head 7 has two hanging positions, and the drilling tool 8 is hung below the hanging positions. Drilling tool 8 is common drilling rod of rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com