A magnetic fluid mechanical arm

A technology of manipulators and magnetic fluids, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems that the manipulator arm cannot be folded, hinders the movement and operation of personnel, and has a fixed telescopic range, so as to achieve rich bending forms and small space occupation , the effect of large bending range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

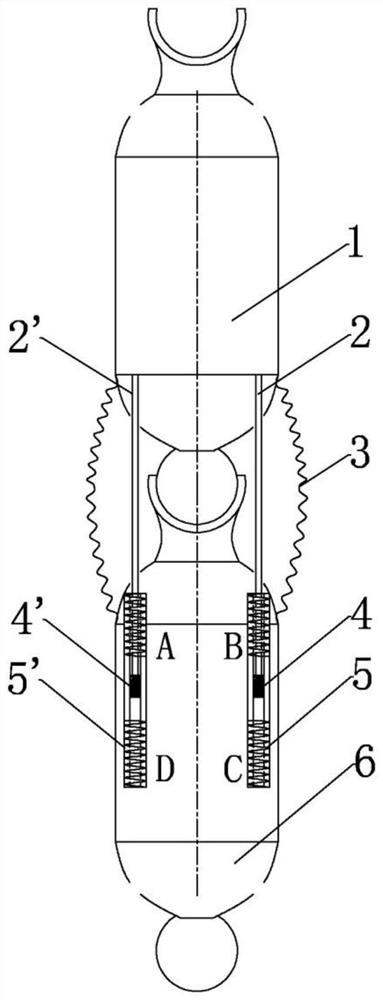

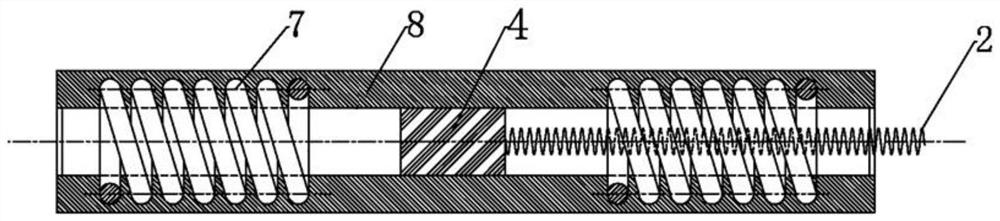

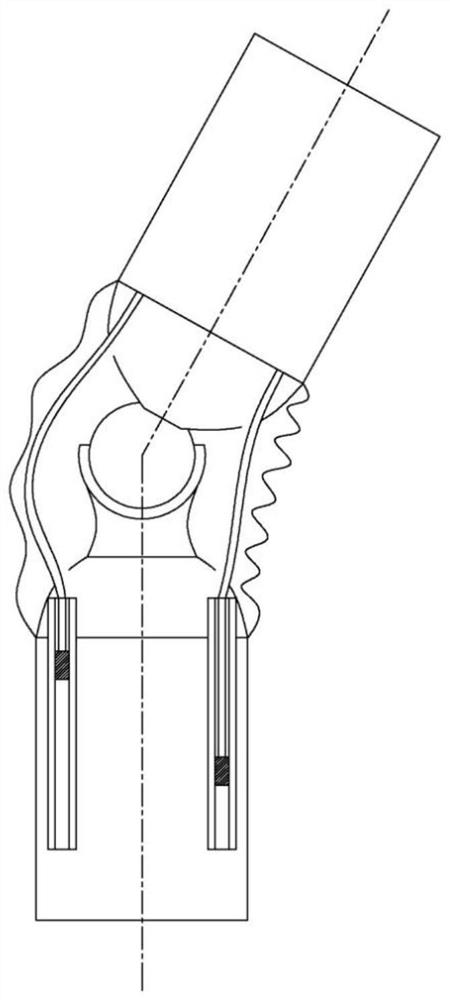

[0020] Such as figure 1 As shown, a magnetic fluid mechanical arm includes an upper limb rod 1 and a lower limb rod 6. The upper limb rod 1 and the lower limb rod 6 are connected by a spherical pair. One end of the foldable rubber sleeve 3 is connected to the upper limb rod 1 and the other end is connected to the The lower limb rod 6 and the folded rubber sleeve 3 protect the junction of the two rods, and can play a buffering role when the upper limb rod is bent. A pair of telescopic drive mechanisms 5 based on magnetic fluid are installed symmetrically in the longitudinal direction on the inner wall of the lower limb rod 6 , and the front end of the lower limb rod 6 has a hole. Such as figure 2 As shown, the telescopic drive mechanism 5 includes a plastic round tube 8, a magnetic fluid slider (4, 4') and a spring rod (2, 2'). The plastic round tube 8 has a coil 7 at both ends, and the coil 7 is connected to the current control device , the magnetic fluid slider (4, 4') can...

Embodiment 2

[0023] On the basis of Embodiment 1, multiple pairs of telescopic drive mechanisms 5 are symmetrically arranged on the lower limb rod 6 , and by cooperatively controlling the spring rods 2 of each telescopic drive mechanism 5 , the upper limb rod 1 can be coordinated and controlled to swing in any direction.

Embodiment 3

[0025] On the basis of Embodiments 1 and 2, the upper limb member 1 and the lower limb member 6 of the multi-section magnetic fluid manipulator are connected end to end to form a multi-section manipulator to achieve multi-stage bending.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com