Color plate-less digital printing machine

A printing machine and digital technology, which is applied in the field of color plateless digital printing machines, can solve the problems of low automation, high labor intensity, and low printing efficiency, achieve high-precision movement, and solve the effect of high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

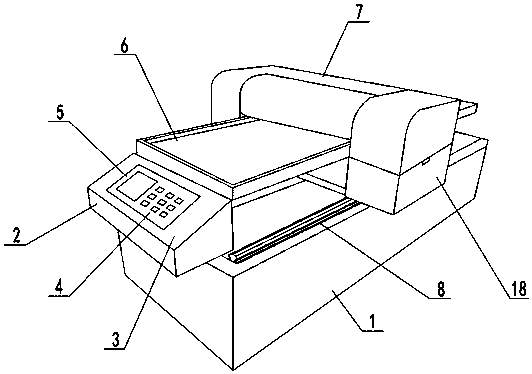

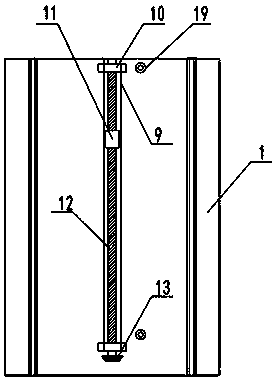

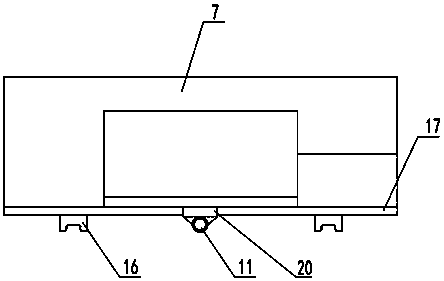

[0019] see Figure 1~4 , in an embodiment of the present invention, a color plateless digital printing machine includes a frame 1, a head 2, a printing plate frame 6 and a printing head 7, the head end of the frame 1 is equipped with the head 2, and the printing plate Frame 6 is fixedly installed on the machine head 2, and is used for placing the article to be printed, from figure 1 It can be seen that the printed board frame 6 has an inwardly recessed positioning cavity. In this embodiment, the printed board frame 6 is especially suitable for the positioning of wood boards, glass, crystals, metal plates, ceramics, etc., and the frame 1 is fixed There are two guide rails 8 arranged along its length direction, and the two feet of the printing head 7 are slidably matched with the guide rails 8, and the ink cartridge 18 is also installed on the printing head 7, and the surface of the frame 1 is also provided with a mounting groove 9 , the screw mandrel 12 is installed through th...

Embodiment 2

[0022] On the basis of Embodiment 1, in order to limit the movement of the printing head 7 , travel switches 19 are installed at both ends of the frame 1 corresponding to the guide rail 8 .

[0023] In order to facilitate the operation of the printing head 7 , a control panel 3 is provided on the printing head 2 , and the control panel 3 includes a display screen 4 and several physical buttons 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com