Freight elevator capable of automatically loading and unloading cargoes

A freight elevator and automatic technology, which is applied in the field of elevators, can solve the problems of goods and elevator damage, troublesome loading and unloading of freight elevators, and low efficiency, so as to reduce labor costs, reduce man-made damage, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

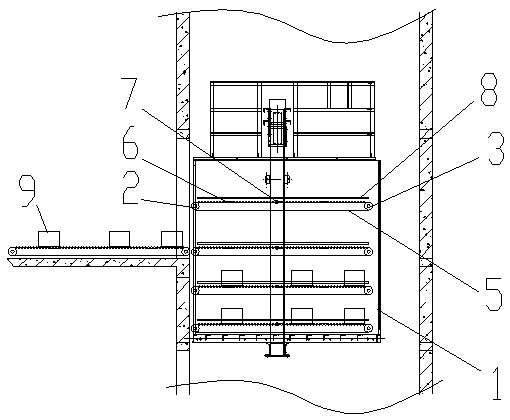

[0026] Example: see figure 1 , a freight elevator capable of automatically loading and unloading goods, including a car 1, a shelf is provided in the car 1, and the shelf includes at least a frame body with an open front side, and several layers are arranged on the frame body from top to bottom Cargo layer, the cargo layer is detachably connected to the frame body, and the distance between two adjacent cargo layers is equal; in the actual production process, the cargo layer is connected to the frame body by bolts; Among them, according to the height of the goods 9, the number of cargo-carrying layers can be reduced, so that the distance between two adjacent cargo-carrying layers can be increased, so as to adapt to the cargoes 9 of different heights. On the frame body, a photoelectric switch 7 is arranged at the position corresponding to each cargo layer, through which it can be detected whether the cargo layer is connected with the frame body, and the photoelectric switch 7 is...

Embodiment 2

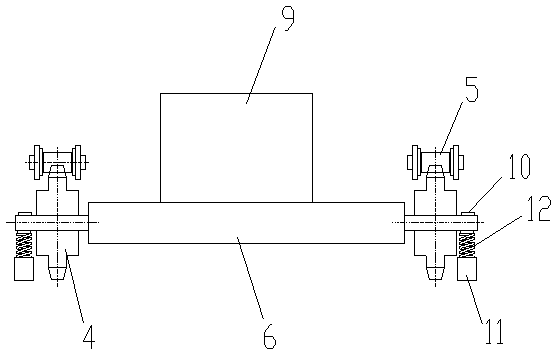

[0037] Example 2: see figure 2 , different from Embodiment 1, on the bracket, a bar-shaped hole is vertically provided at the positions corresponding to the two ends of the transmission rod 6, and the two ends of the transmission rod 6 are located in the bar-shaped hole, and can move up and down along the bar-shaped hole ; The drive chain 5 is bypassed from the upper side of the drive sprocket 4 and combined with the drive sprocket 4 . An opening and closing structure is provided directly below both ends of the transmission rod 6 , and the opening and closing structure includes a transmission seat 10 , an electromagnetic chuck 11 and a return spring 12 . The upper end of the return spring 12 is connected with the transmission seat 10, and the lower end is connected with the electromagnetic chuck 11; the electromagnetic chuck 11 is fixedly connected with the chassis. The transmission seat 10 is connected to the end of the transmission rod 6, and the transmission rod 6 is rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com