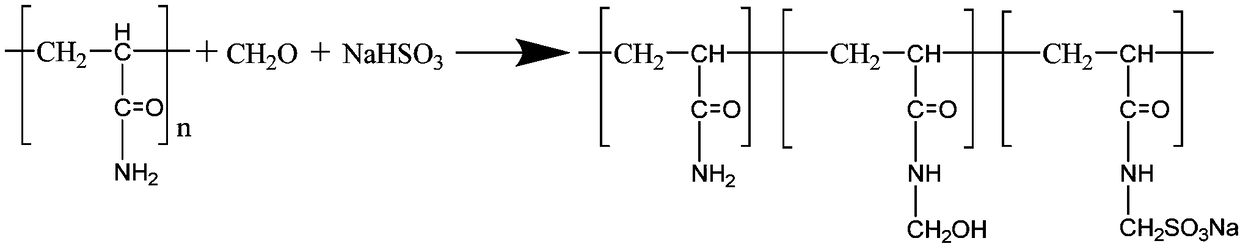

Sulfonate hydroxymethyl polyacrylamide and synthesis method thereof

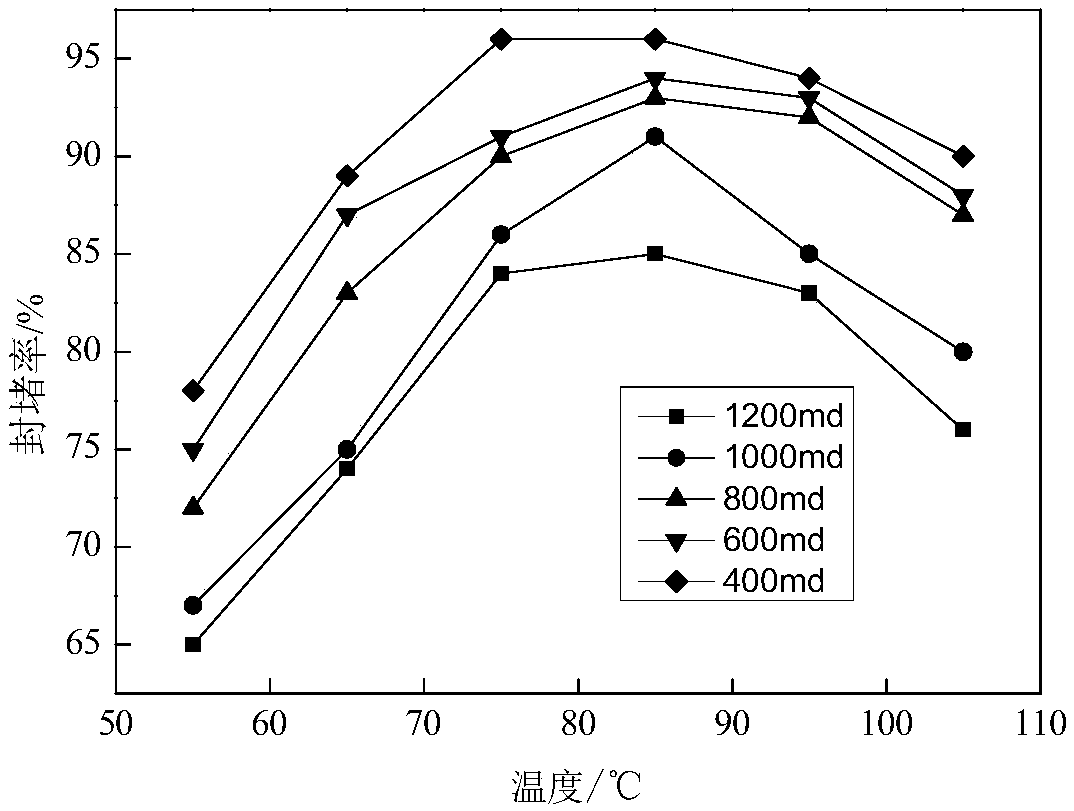

A technology of sulfonic acid hydroxymethyl polyacrylamide and sulfonic hydroxymethyl polyacrylamide, which is applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as inability to meet practical application conditions, and achieve The effect of low production cost, less time-consuming and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

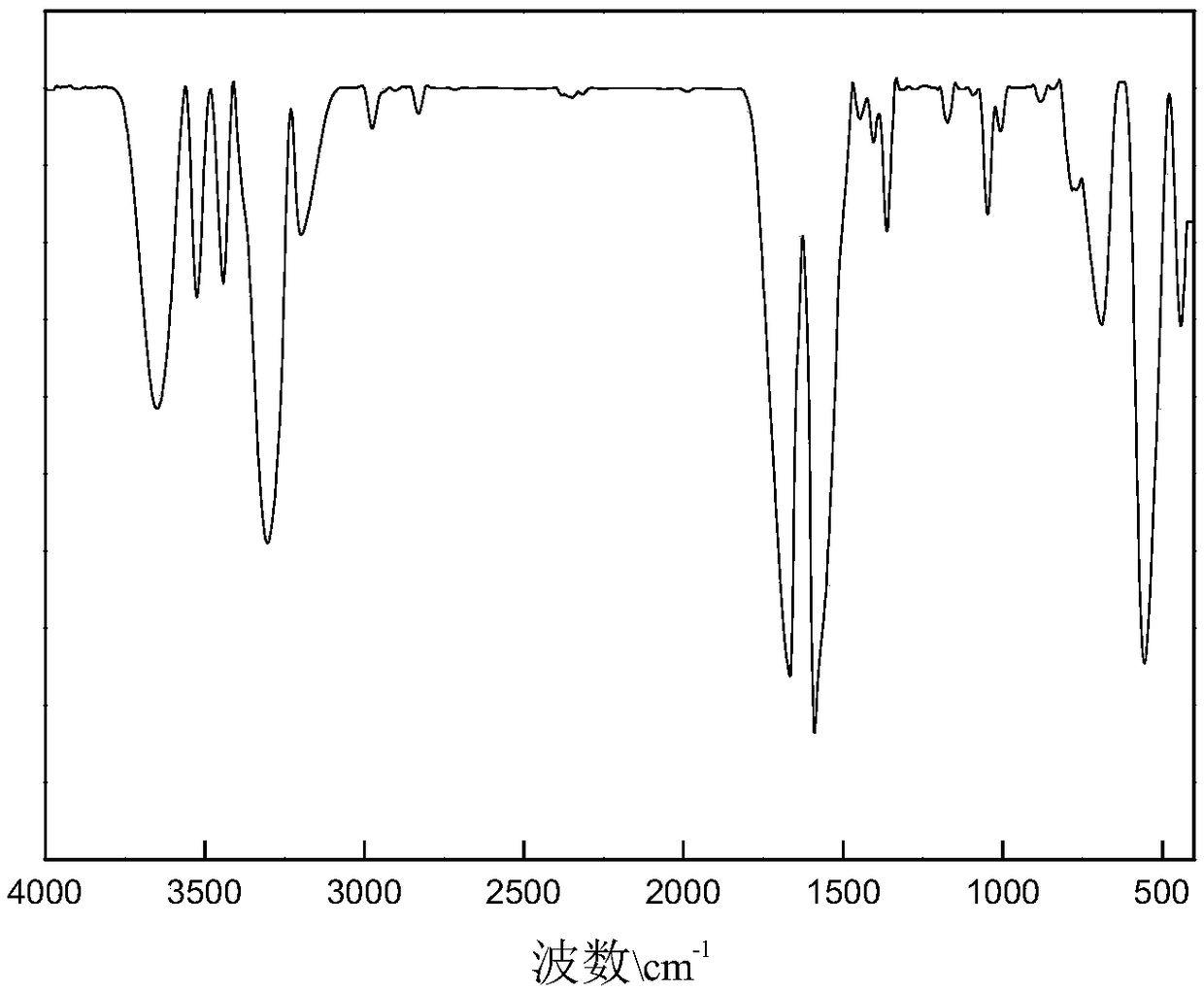

[0027] The invention discloses a preparation method of sulfonic acid methylol polyacrylamide, which specifically comprises the following steps:

[0028] Step 1, mix polyacrylamide (PAM) and purified water according to the ratio of material to liquid (2-3) g: (10-20) mL, and stir until PAM is fully dissolved to obtain a PAM solution;

[0029] Step 2, mix sodium bisulfite (NaHSO 3 ) and purified water, stirred to NaHSO 3 fully dissolved to produce NaHSO 3 Solution; mix PAM solution and NaHSO according to volume ratio (20-40):(5-8) 3 solution and stir evenly to prepare mixed solution A;

[0030] Step 3, adjust the pH value of the mixed solution A to 9-11 through a sodium hydroxide (NaOH) solution with a mass fraction of 30-40%, to obtain a mixed solution B, and place the mixed solution B in a three-necked flask;

[0031] Step 4, adding formaldehyde (HCHO) to the mixed solution B, so that the mass fraction of the added formaldehyde in the mixed solution is 4-5%, to obtain the ...

Embodiment 1

[0042] Prepare PAM solution according to the solid-liquid ratio of 2.5:15, and prepare NaHSO according to the solid-liquid ratio of 0.5:6 3 Solution, mix PAM solution and NaHSO according to volume ratio 20:8 3 solution and stirred evenly to prepare mixed solution A; adjust the pH value of mixed solution A to 10 by mass fraction of 30% NaOH solution to obtain mixed solution B, and place mixed solution B in a three-necked flask; add formaldehyde to make formaldehyde in The mass fraction in the reaction solution is 4%, and the mixed solution C is prepared; the mixed solution C is heated to 70°C, and reacted at this temperature for 2 hours to obtain a colorless and transparent liquid D; the liquid D is separated by absolute ethanol to obtain a precipitate , and dried the precipitate at 55°C to obtain a white solid, which is a sulfonic acid methylol polyacrylamide copolymer.

Embodiment 2

[0044] Prepare 2:20 PAM solution according to the ratio of solid to liquid, prepare NaHSO according to the ratio of solid to liquid 0.5:8 3 Solution, mix PAM solution and NaHSO according to volume ratio 20:6 3 solution and stirred evenly to prepare mixed solution A; adjust the pH value of mixed solution A to 9 by mass fraction of 40% NaOH solution to obtain mixed solution B, and place mixed solution B in a three-necked flask; add formaldehyde to make formaldehyde in The mass fraction in the reaction solution is 5%, and the mixed solution C is prepared; the mixed solution C is heated to 75°C, and reacted at this temperature for 4 hours to obtain a colorless and transparent liquid D; the liquid D is separated by absolute ethanol to obtain a precipitate , Dry the precipitate at 60°C to obtain a white solid, which is a sulfonic acid methylol polyacrylamide copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com