Waterborne roller-coating artistic coating and preparation method thereof

A technology of art paint and roller coating, applied in multi-color effect paint and other directions, can solve the problems of invisibility of multiple color spots, difficult construction, and long construction service period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

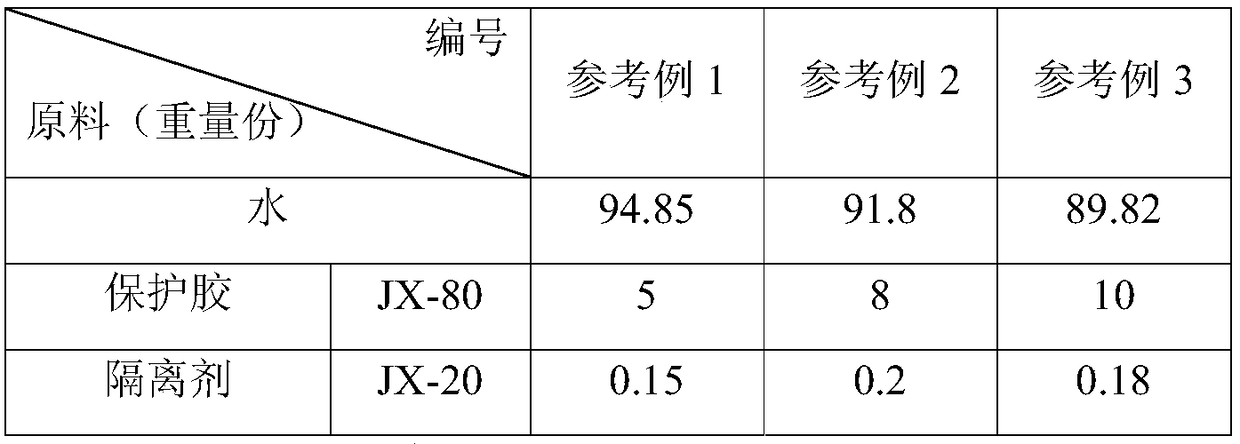

[0069] Reference example 1 for the preparation method of B2 component protective colloid aqueous solution

[0070] According to the weight parts of the raw materials in Reference Example 1 described in Table 1, add water into the batching tank, add protective glue and disperse for 20 minutes to a transparent state under stirring at a speed of 600r / min, and then add a release agent under stirring at a speed of 600r / min , dispersed for 20 minutes to a transparent gel-free state, and after standing for 20 hours, the protective glue solution 1 was obtained.

[0071] Reference example 2 of the preparation method of B2 component protective colloid aqueous solution

[0072] According to the weight parts of the raw materials in Reference Example 2 described in Table 1, add water into the batching tank, add protective glue and disperse for 40 minutes to a transparent state under stirring at a speed of 800r / min, and then add a release agent under stirring at a speed of 800r / min , dispe...

Embodiment 1~3

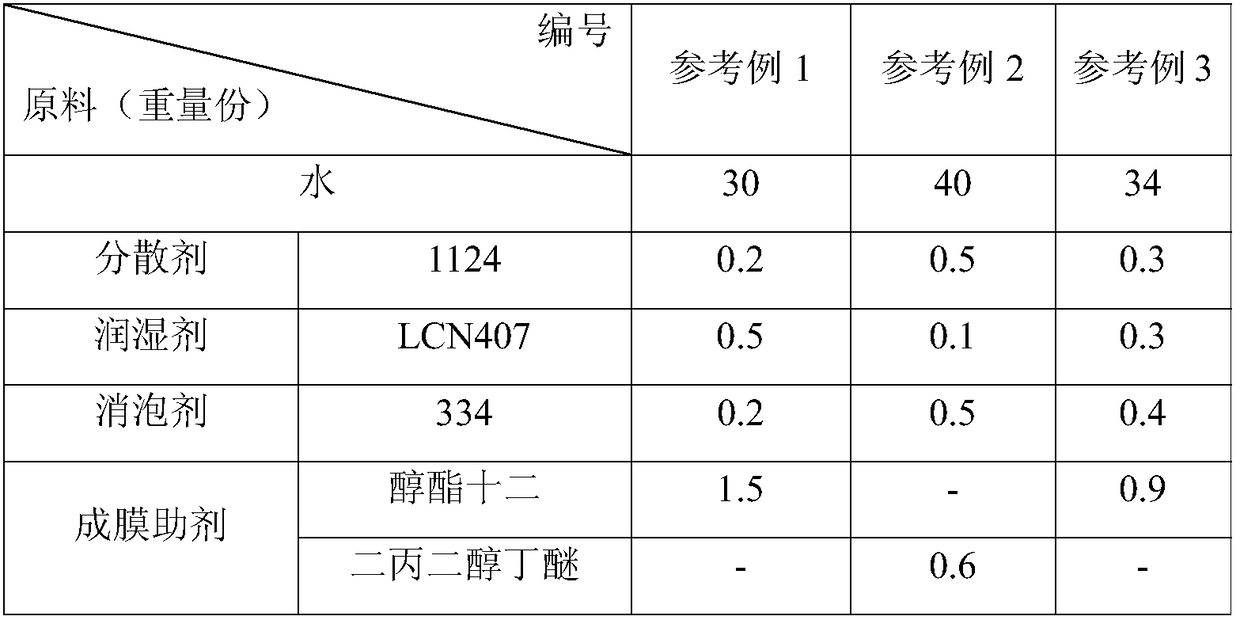

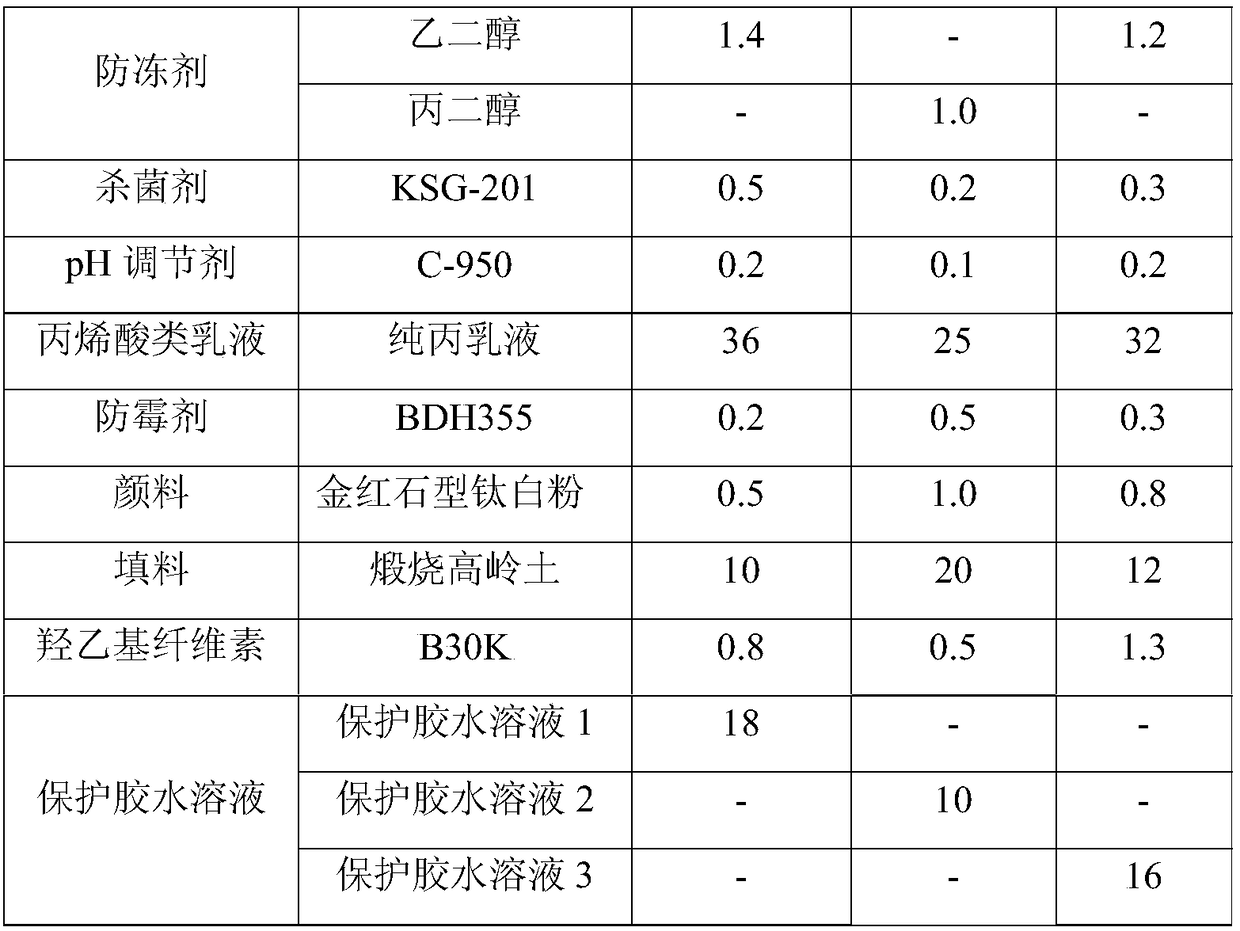

[0099] The raw material components and proportioning ratio of water-based roller coatable art paint examples 1 to 3 are shown in Table 4:

[0100] Table 4 water-based roll coatable art paint embodiment 1-3 raw material components and proportioning table

[0101]

[0102]

Embodiment 1

[0104] (1) The preparation method of B component: according to the weight parts of each raw material in Example 1 described in Table 4, the B1 component is added to the B2 component with a mass ratio of 1:0.8, and at a speed of 600r / min, Disperse to a particle size of 5 mm to obtain component B;

[0105] (2) Preparation method of water-based roll-coatable art paint: add component A to component B obtained in step (1) at a mass ratio of 1:1.17, and disperse until the particle size is ≤ 60 μm, to obtain water-based roll-coatable art paint 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com