Absorption type condensation industrial waste heat recovery system

A technology of industrial waste heat and recovery system, which is applied in the field of industrial waste heat recovery, can solve the problems of power consumption and water resources, high cost of clean energy, energy waste, etc., and achieve fast absorption and release speed and good effect of waste heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

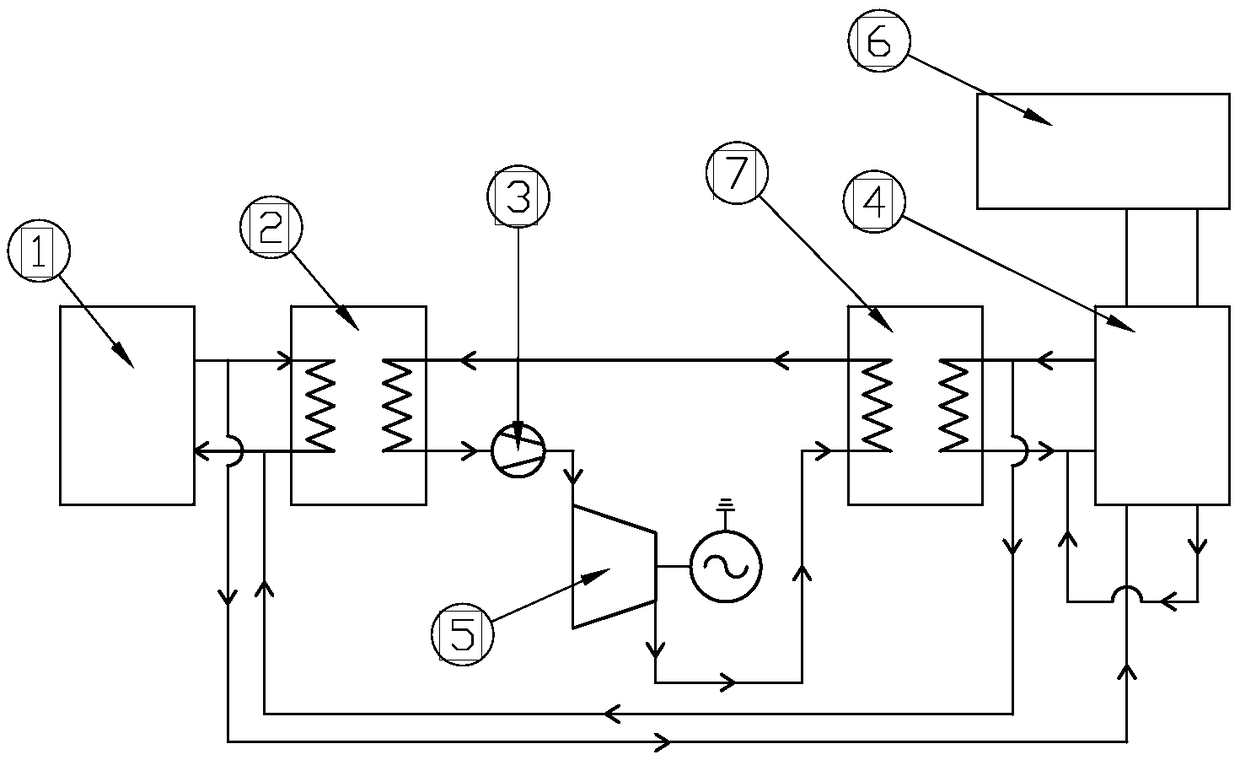

[0010] An industrial waste heat recovery system of absorption condensation, including industrial waste heat 1, evaporator 2, compressor 3, absorption heat pump 4, working medium generator 5, heat user 6, and condenser 7; the industrial waste heat 1 separates the waste heat transported to the evaporator 2, the absorption heat pump 4, the evaporator 2 evaporates the refrigerant, and uses the compressor 3 to heat the refrigerant, and transports the refrigerant to the working medium generator 5 for work, and the working medium still has a certain temperature after work. The condensed water in the condenser 7 is used as the low-temperature heat source of the absorption heat pump 4, and the first part of the waste heat of the industrial waste heat 1 is used as the driving heat source of the absorption heat pump 4, and the obtained heat source is used to deliver to the heat user 6 for Heating, drive the heat source to work and transport back the industrial waste heat 1.

[0011] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com