Economical water tank dedusting reversing fan device

An economical, water tank technology, applied in the direction of non-variable pumps, engine components, machines/engines, etc., can solve the problems of difficulty in manual dust removal, unfavorable processing and production, and easy formation of dust and other problems, so as to solve the problem of long-term exposure and facilitate Processing and production, the effect of simple structure of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

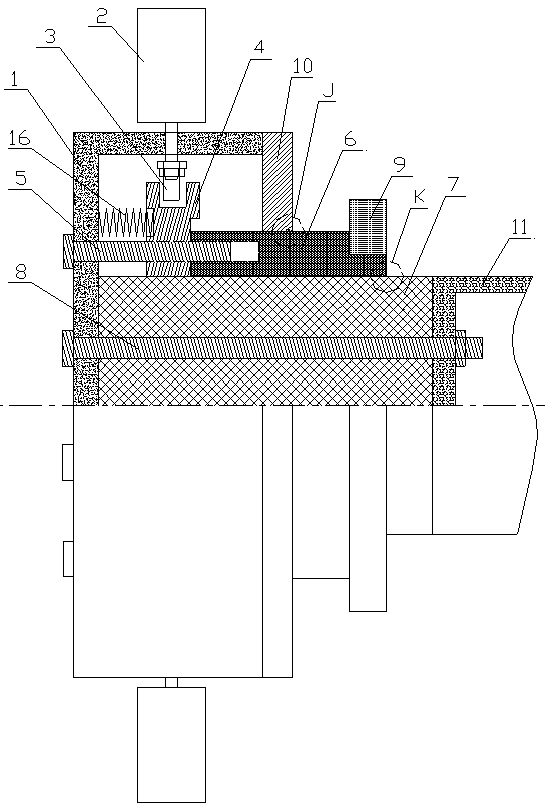

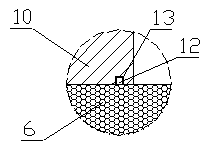

[0016] Embodiment 1: as figure 1 , image 3 and Figure 4 As shown, a new type of water tank dust removal reversing fan device includes a housing 1, blades 2, small shift fork 3, center positioning gear 4, spring 16, guide rod 5, transmission sleeve 6, central shaft 7, main bearing 9 and shell Cover 10; the outer circumference of the housing 1 is provided with blades 2, the blades 2 pass through the housing 1 and are fixedly connected with the small shift fork 3, the small shift fork 3 is in movable contact with the center positioning gear 4, and the center positioning The right side of the gear 4 is fixedly connected to the transmission sleeve 6, and the center positioning gear 4 and the transmission sleeve 6 are provided with guide holes at corresponding horizontal positions, and the guide rod 5 is fixed to the housing 1 and slides sequentially through the guide holes Connected to the central positioning gear 4 and the transmission sleeve 6, the central positioning gear 4 ...

Embodiment 2

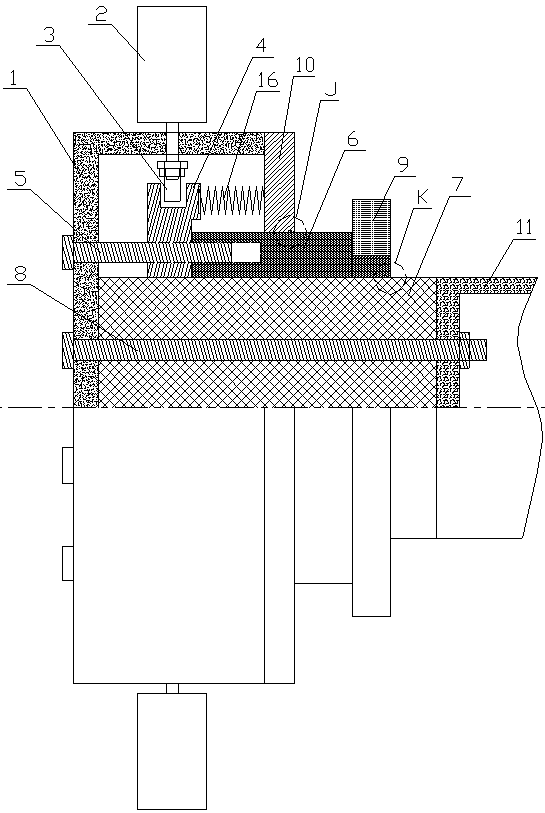

[0017] Embodiment 2: as figure 2 , image 3 and Figure 4 As shown, a new type of water tank dust removal reversing fan device includes a housing 1, blades 2, small shift fork 3, center positioning gear 4, spring 16, guide rod 5, transmission sleeve 6, central shaft 7, main bearing 9 and shell Cover 10; the outer circumference of the housing 1 is provided with blades 2, the blades 2 pass through the housing 1 and are fixedly connected with the small shift fork 3, the small shift fork 3 is in movable contact with the center positioning gear 4, and the center positioning The right side of the gear 4 is fixedly connected to the transmission sleeve 6, and the center positioning gear 4 and the transmission sleeve 6 are provided with guide holes at corresponding horizontal positions, and the guide rod 5 is fixed to the housing 1 and slides sequentially through the guide holes Connected to the central positioning gear 4 and the transmission sleeve 6, the central positioning gear 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com