Copper-clad wire oxidation tester convenient to move

An oxidation test and copper-clad wire technology, which is applied to mobile frames, engine frames, instruments, etc., can solve the problems of inconvenient movement, inability to stretch copper-clad wires, and inability to classify and store oxidation wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

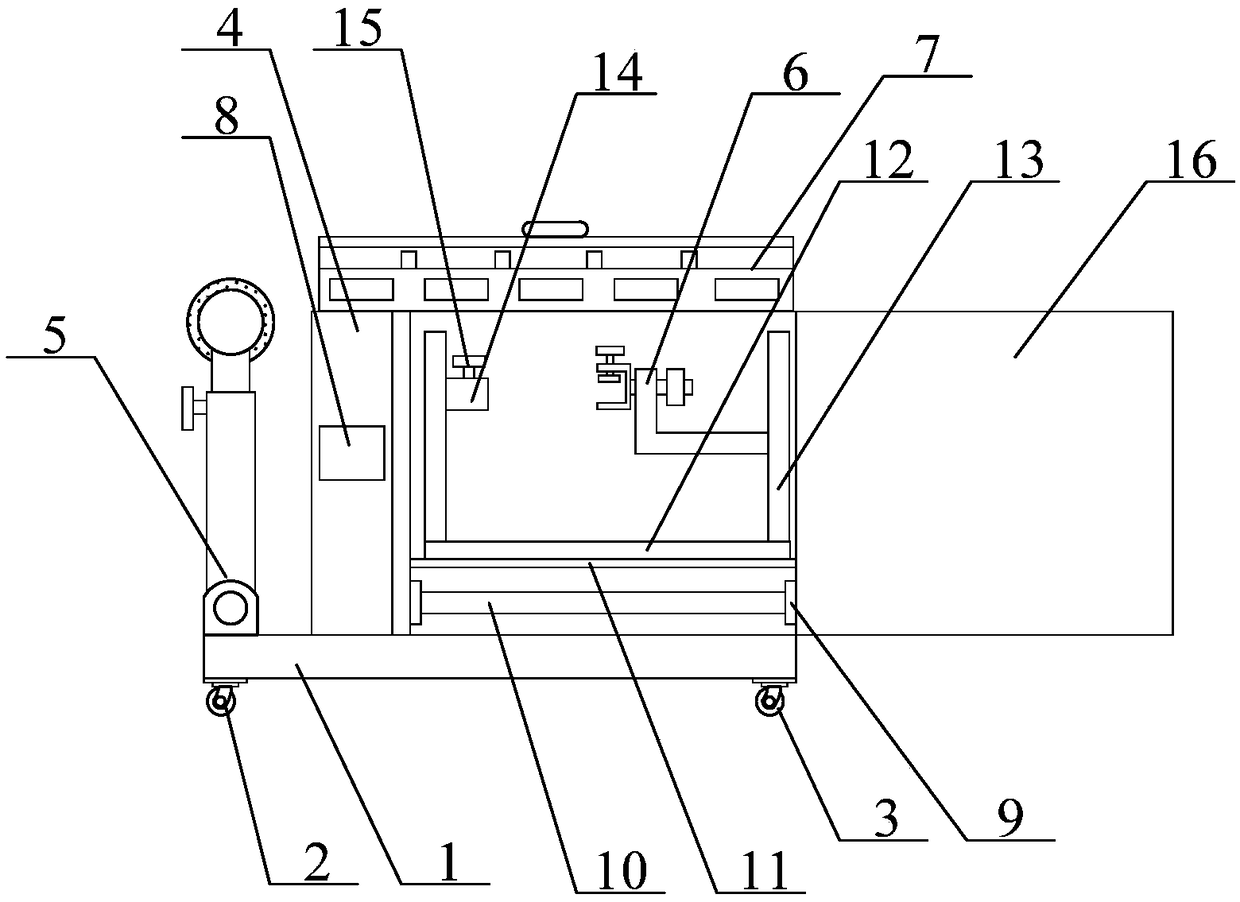

[0031] The present invention will be specifically described below in conjunction with the accompanying drawings.

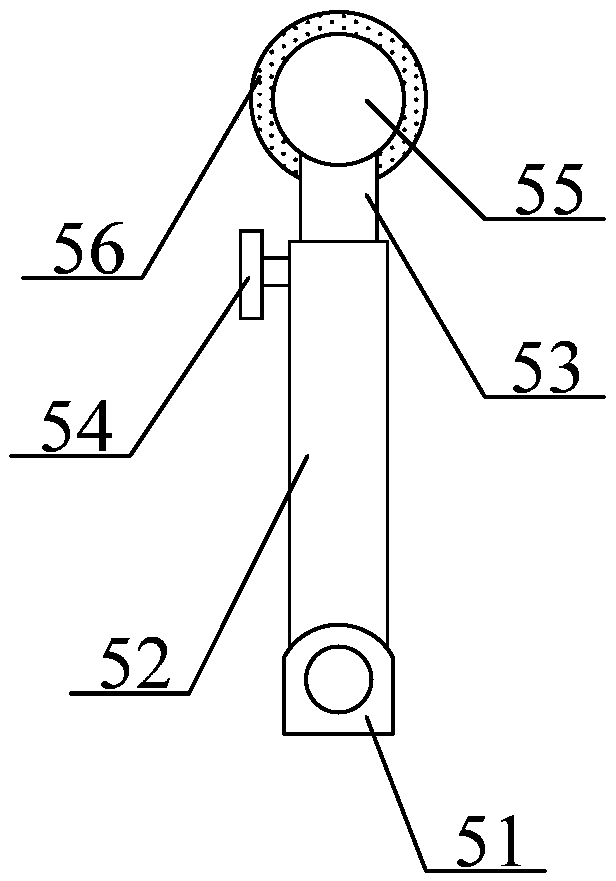

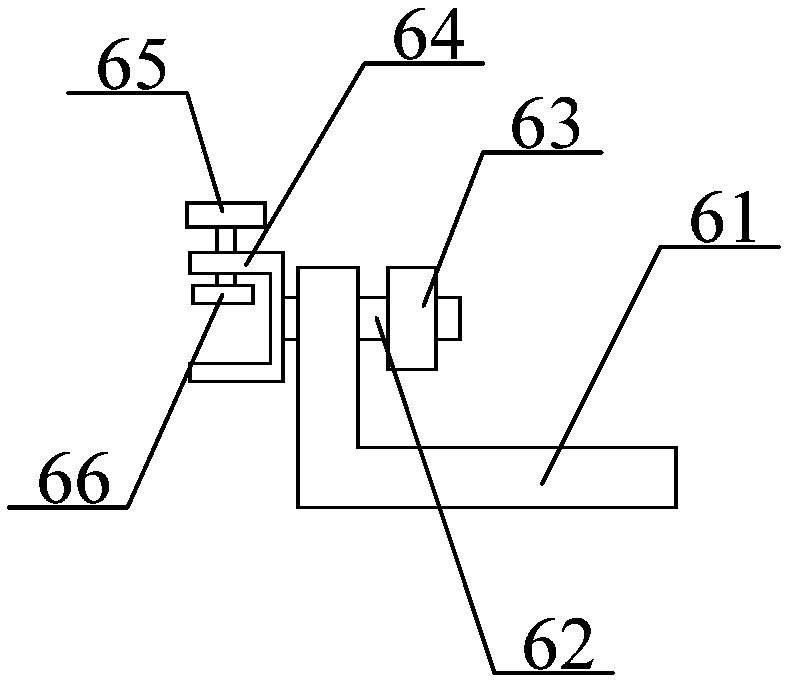

[0032] Such as figure 1 and figure 2 As shown, a copper-clad wire oxidation tester that is convenient to move according to the present invention includes a moving plate 1, a universal wheel 2, a directional wheel 3, a drying oxidation box 4, a rotating and adjusting pulling rod structure 5, and a fixed pulling rod structure 5. Stretching rod structure 6, storage sorting box structure 7, power switch 8, mounting seat 9, heating pipe 10, heating plate 11, placing plate 12, fixing plate 13, locking tube 14, jacking bolt 15 and box door 16, all The universal wheel 2 bolts are connected to the left side of the lower end of the mobile plate 1; the directional wheel 3 bolts are connected to the right side of the lower end of the mobile plate 1; On the right side; the rotation adjustment pull rod structure 5 is installed on the left side of the upper end of the moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com