A mixing machining process design system

A technology of process design and mixer, applied in the direction of design optimization/simulation, calculation, instrument, etc., can solve the problem of not guaranteeing the rationality and applicability of process design, difficult to understand accurately, etc. The effect of three-dimensionalization and improvement of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

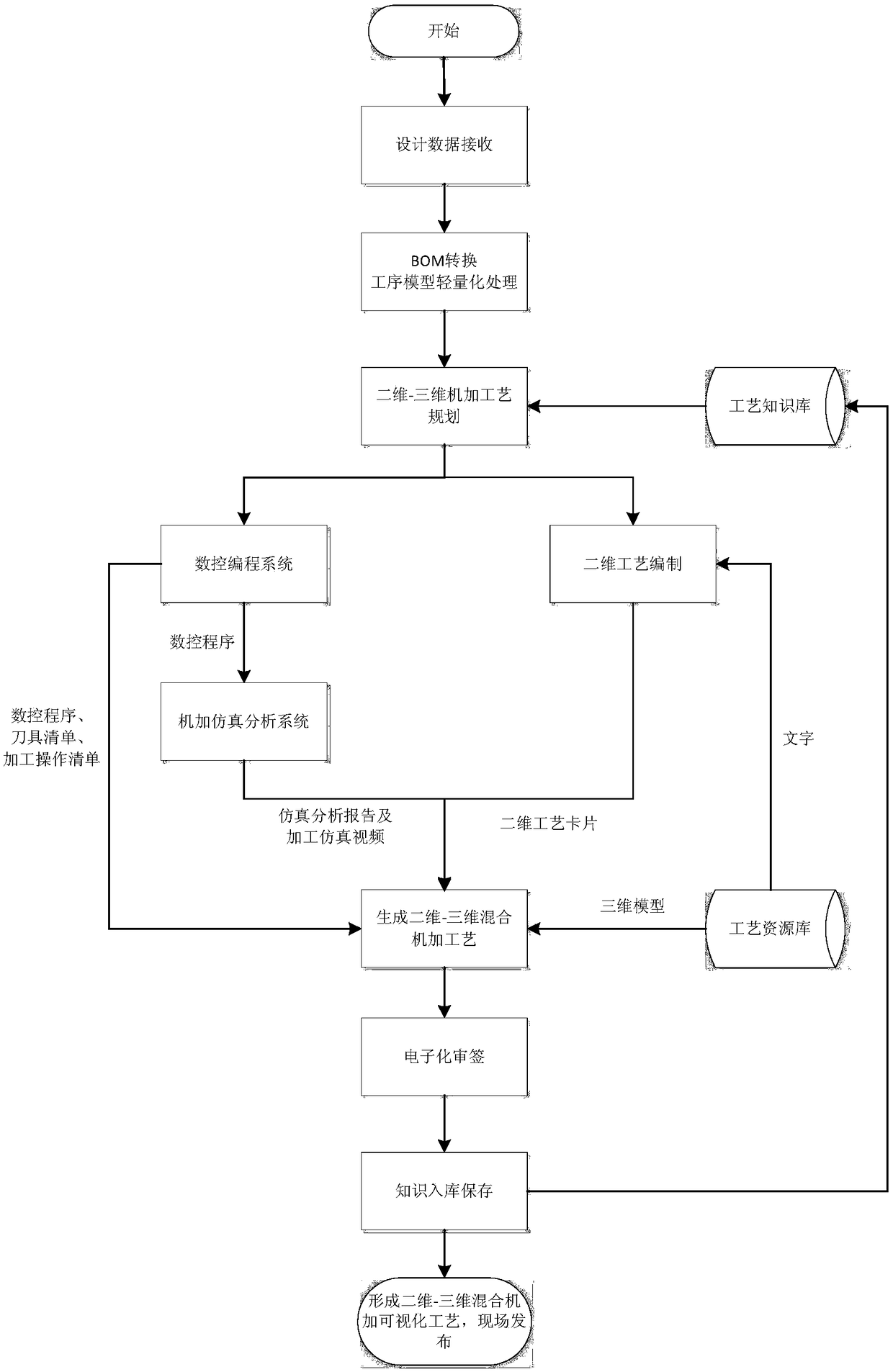

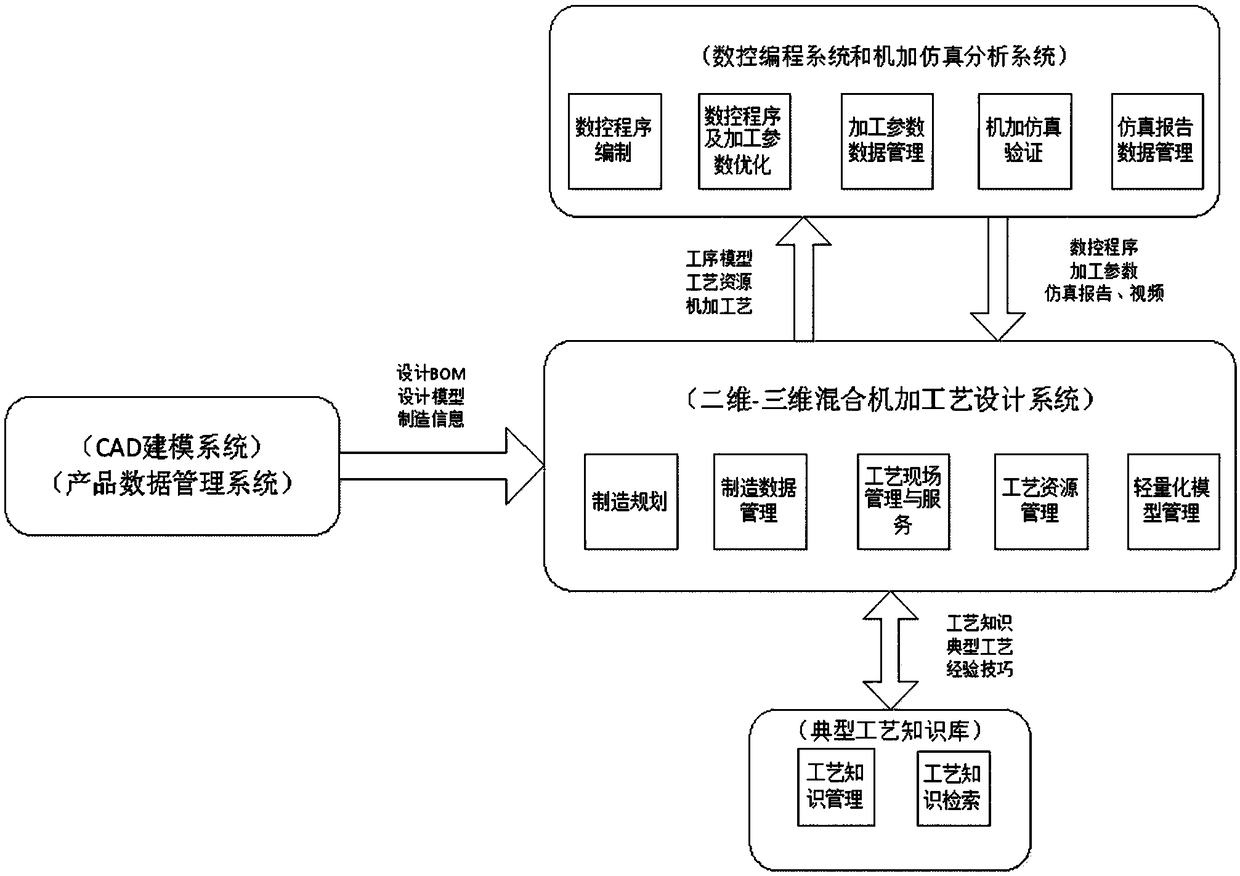

[0018] 1) The manufacturing process management system receives product data from the product data management system, including product 3D model, product BOM, manufacturing information, technical requirements, etc.;

[0019] 2) Edit based on the design data in the manufacturing process management system, convert the design EBOM into a process PBOM, and carry out lightweight processing of the design data;

[0020] 3) Find the closest machining scheme by calling the typical knowledge base, and select the two-dimensional or three-dimensional process design mode according to the complexity of the machining features, and initially formulate the machining scheme. The simple machining features adopt the two-dimensional machining process design mode, and the complex The processing characteristics adopt the three-dimensional machining process design mode;

[0021] 4) The two-dimensional machining process design directly calls the two-dimensional process card for compilation, and the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com