Method, device, apparatus and system for calibrating initial angle of motor resolver

A calibration method and initial angle technology, applied in the estimation/correction of motor parameters, etc., can solve the problems of long process time and calibration error, and achieve the effect of improving calibration efficiency and eliminating the risk of mistakes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0034] For the convenience of understanding, the nouns involved in the embodiments of the present invention are explained below:

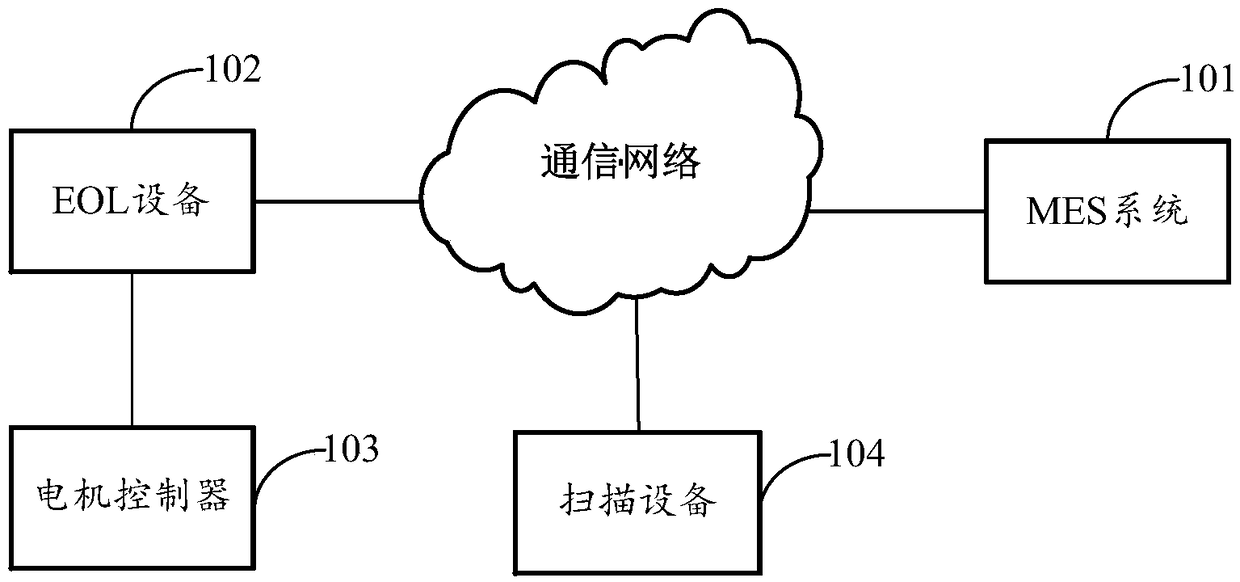

[0035] EOL, End of Line Testing Tool, is the end of line testing equipment used in the car production line to meet the functional testing and product configuration before the product goes off the line.

[0036] Manufacturing Execution System (MES, Manufacturing Execution System), that is, production information management system, can optimize all the information required for production activities from order input to product completion: it uses timely and accurate information to guide, start, respond and record production activities ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com