Flat plate mop cloth capable of being fast dried

A flat mop, fast drying technology, applied in the direction of cleaning floors, carpets, cleaning equipment, etc., can solve the problems of moldy and smelly mop cloth, long-term drying, affecting use, etc., to achieve simple structure, avoid bacteria stink and rot, cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

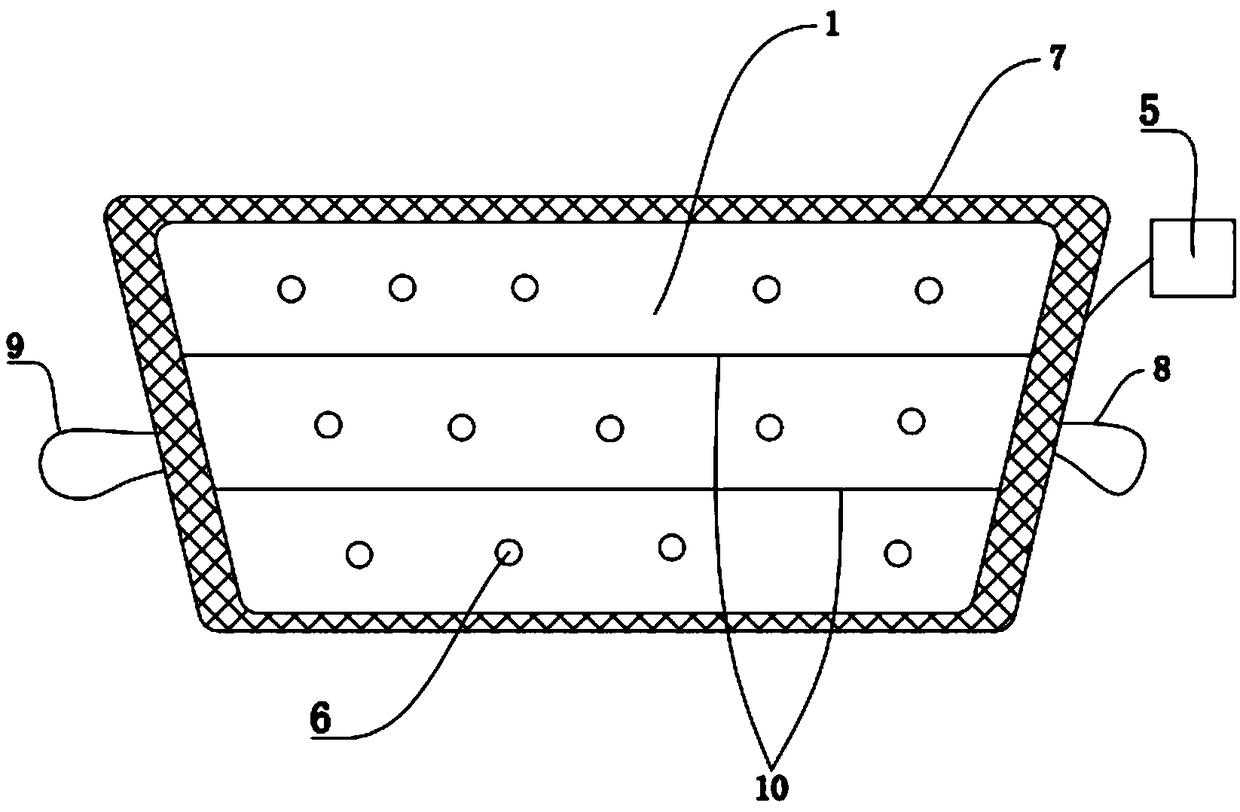

[0028] Such as figure 1 As shown, a new type of mop cloth includes a mop cloth body 1, the mop cloth body 1 is sewn around a layer of velcro cloth 3 and a layer of wiping cloth 2, and the velcro cloth 3 is used for gluing on the flat mop head On, wiping cloth 2 is used for contacting with ground, wipes ground. On the mop cloth body 1, that is, the Velcro cloth 3 and the wiping cloth 2 are pressed with a pressure line 10, and the pressure line 10 can be arranged parallel to the long side of the mop cloth body 1, or perpendicular to the long side of the mop cloth body 1. This solution The middle is preferably arranged parallel to the long side of the mop cloth body 1, which can reduce the number of crimping lines 10 and reduce the amount of processing.

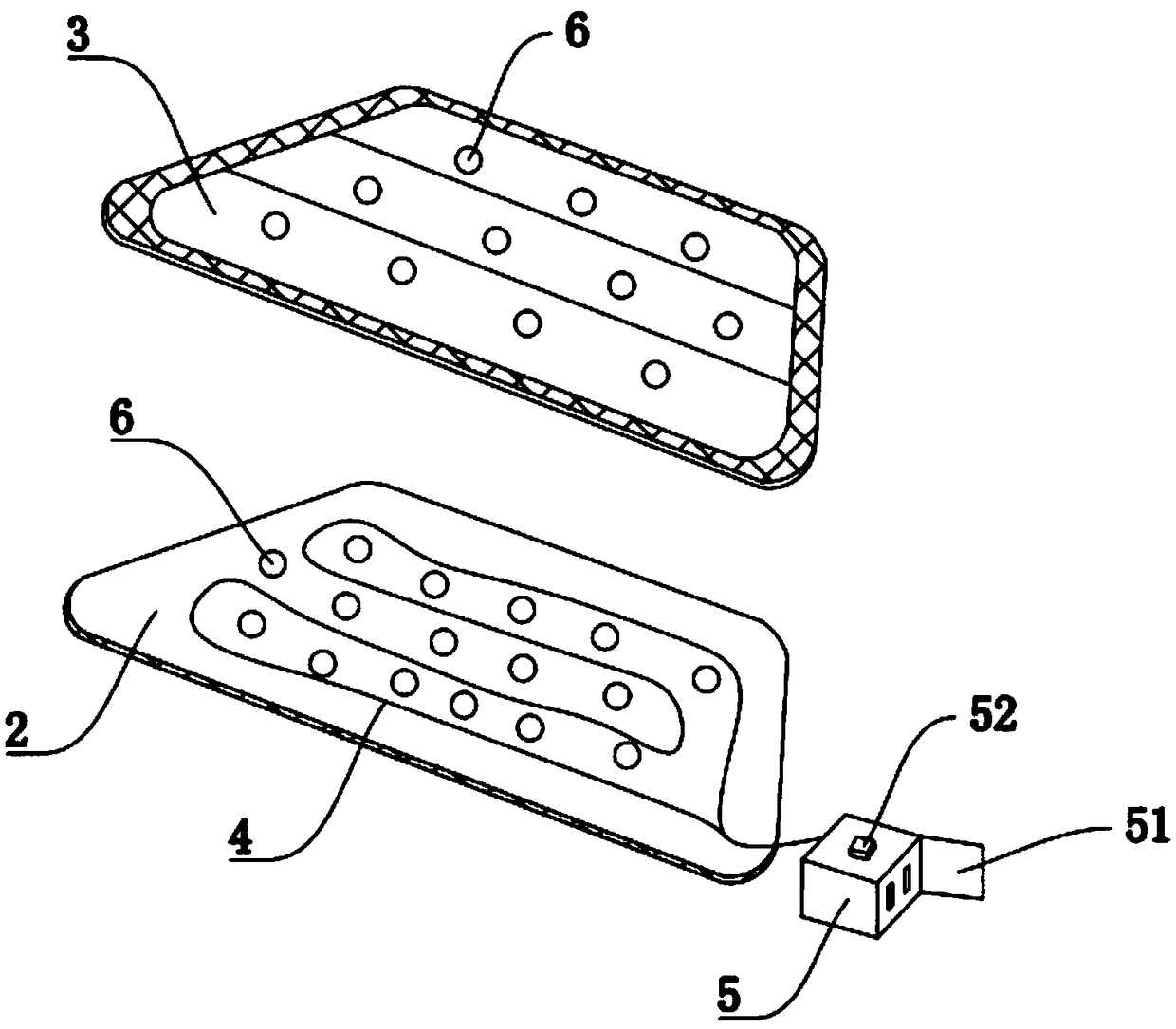

[0029] Such as figure 2 As shown, a heating wire 4 is arranged between the hook and loop cloth 3 and the wiping cloth 2, and the heating wire 4 can be fixed on the side of the hook and loop cloth 3 close to the wiping cloth 2...

Embodiment 2

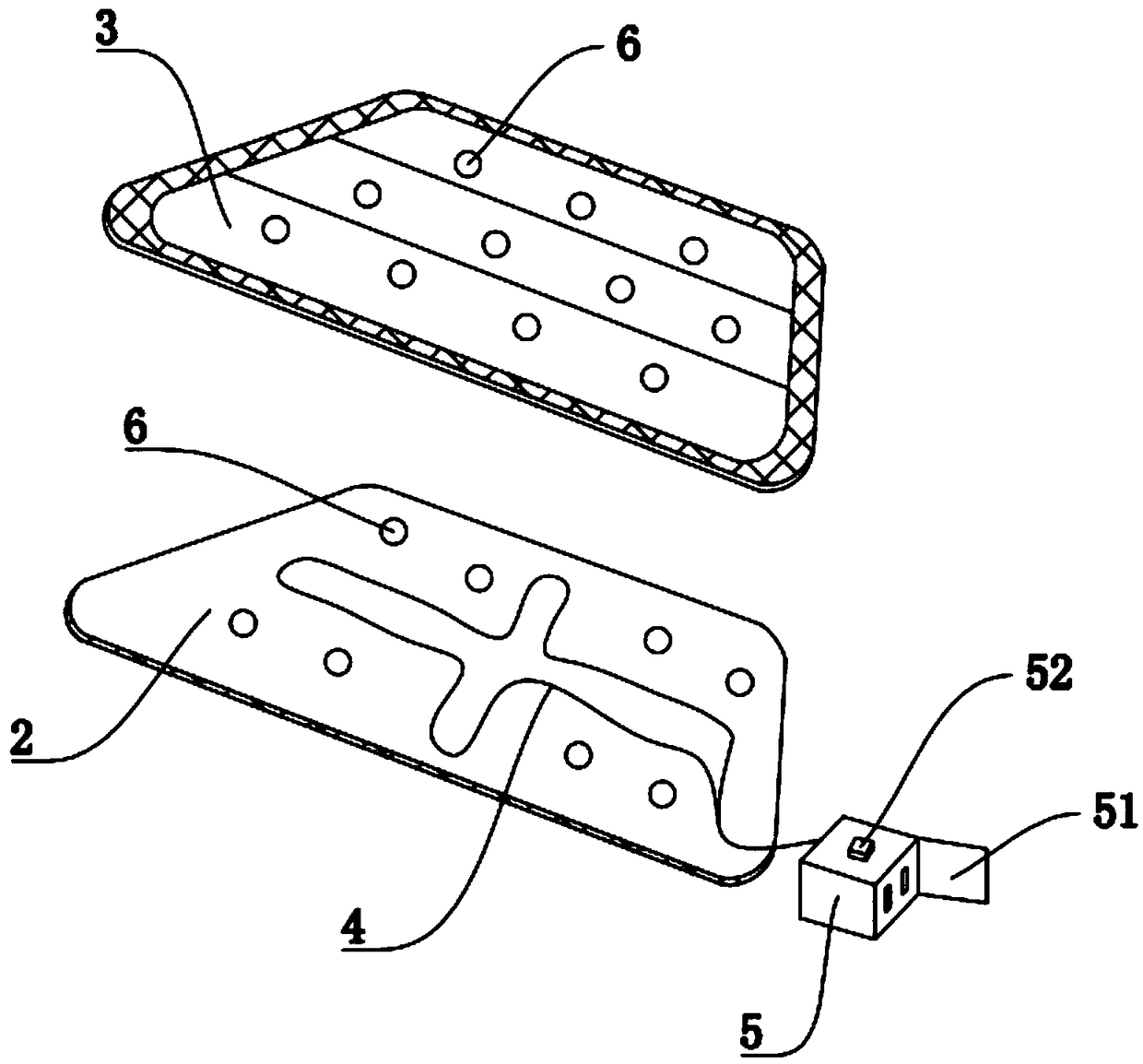

[0032] Such as image 3 As shown, the difference between this embodiment and embodiment 1 is that the heating wire 4 is flatly laid in a cross shape between the hook and loop cloth 3 and the wiping cloth 2 . The cross-shaped laying is another form of laying the heating wire 4. The cross-shaped laying extends to the front, rear, left, and right sides of the mop cloth body 1, so that the heating wire 4 is evenly laid in the space between the hook and loop cloth 3 and the wiping cloth 2. , heating makes the mop cloth easy to dry.

[0033] By fixing the heating wire 4 between the hook and loop cloth 3 of the mop body 1 and the wiping cloth 2, the heating wire 4 is laid on a plane between the two, occupying all directions of front, back, left, and right, and the heating wire 4 can be connected through a USB connector 5 The power supply heats it. When mopping the floor, the heating wire 4 becomes the strong force point in the mop cloth body 1. When the mop cloth is pressed, it scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com