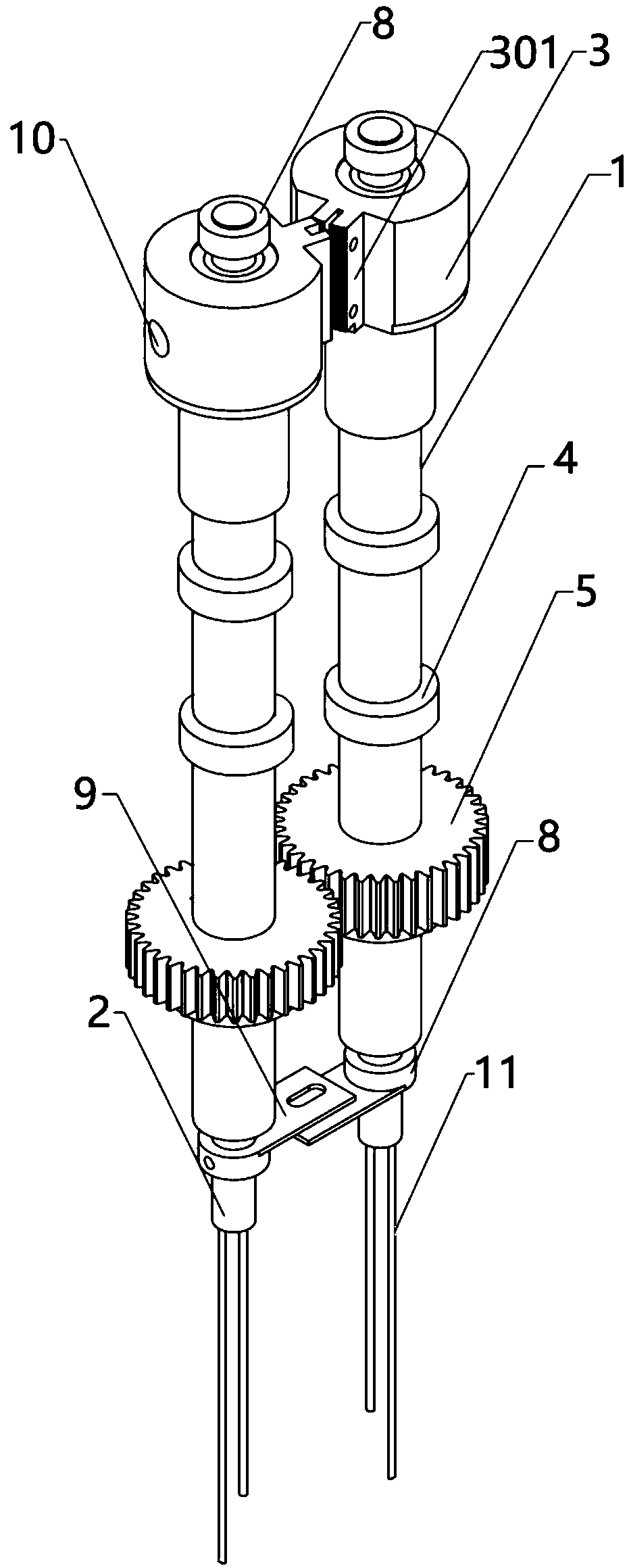

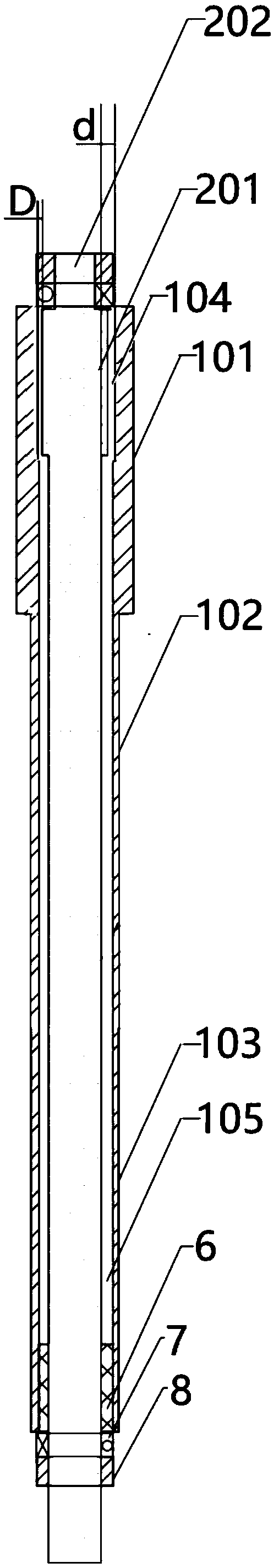

Heat sealing device suitable for narrow seal of packaging machine

A heat sealing device, packaging machine technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of increased operation and maintenance costs, accelerated parts wear, high manufacturing costs, and reduced manufacturing costs and maintenance. The effect of workload, ease of use and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Here, it should be noted that the functions, methods, etc. involved in the present invention are only conventional adaptive applications of the prior art. Therefore, the improvement of the present invention to the prior art lies in the connection relationship between the hardware, rather than the functions and methods themselves. Improve. The description of the functions and methods in the present invention is to better illustrate the present invention so as to better understand the present invention.

[0030] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0031] It should be noted that, unless otherwise specified, the technical terms or scientific terms used...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap