Luggage conveying equipment

A technology for conveying equipment and luggage, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of complex assembly line structure, large space occupation, and high use cost, and achieve high transportation effect, small space occupation, and use. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

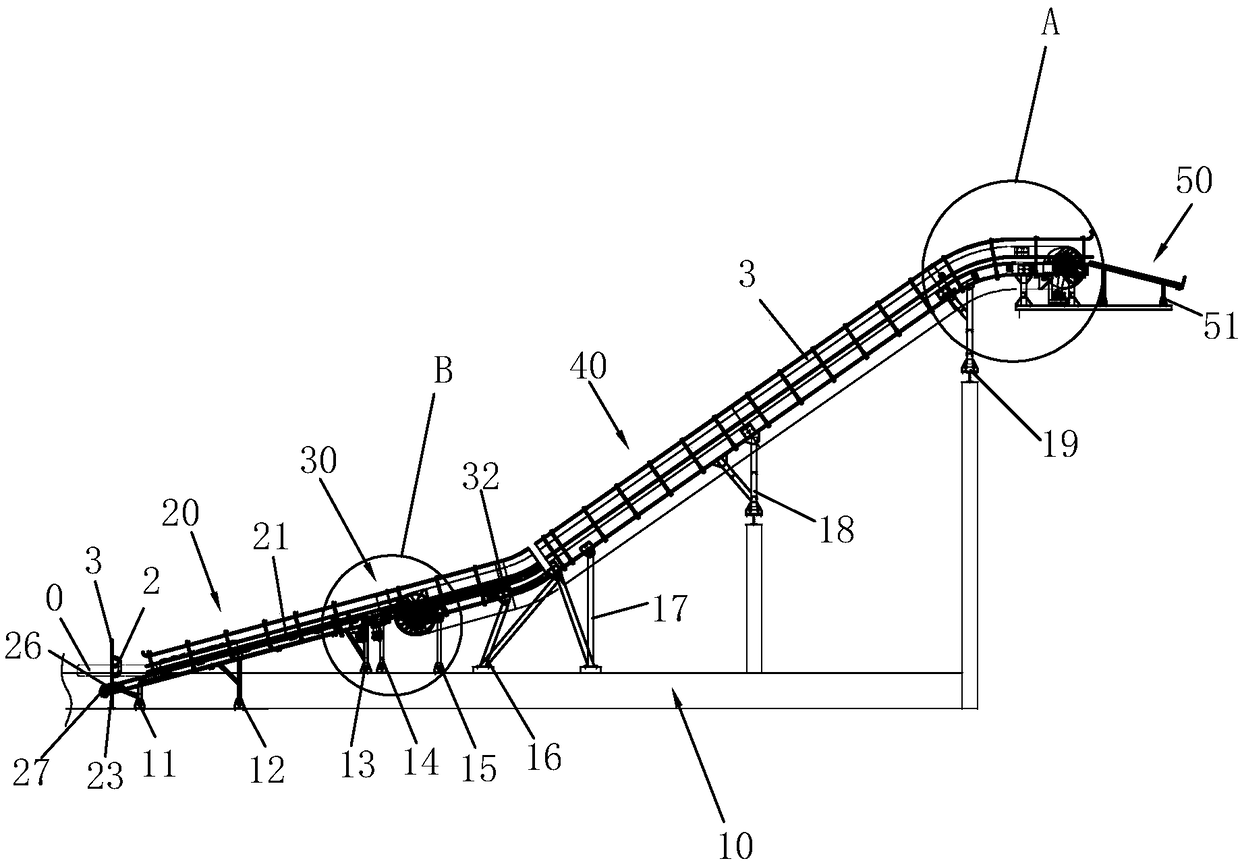

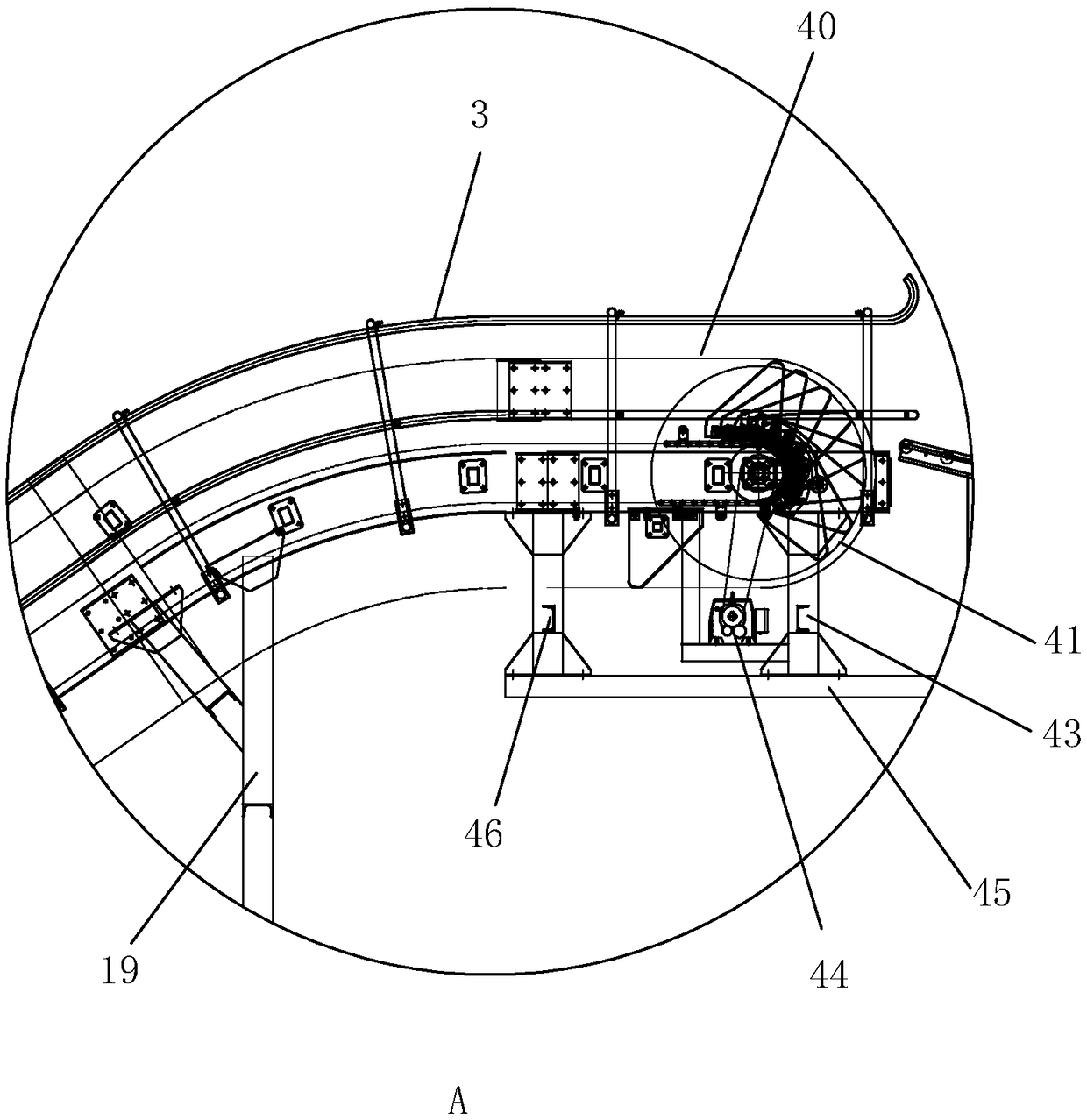

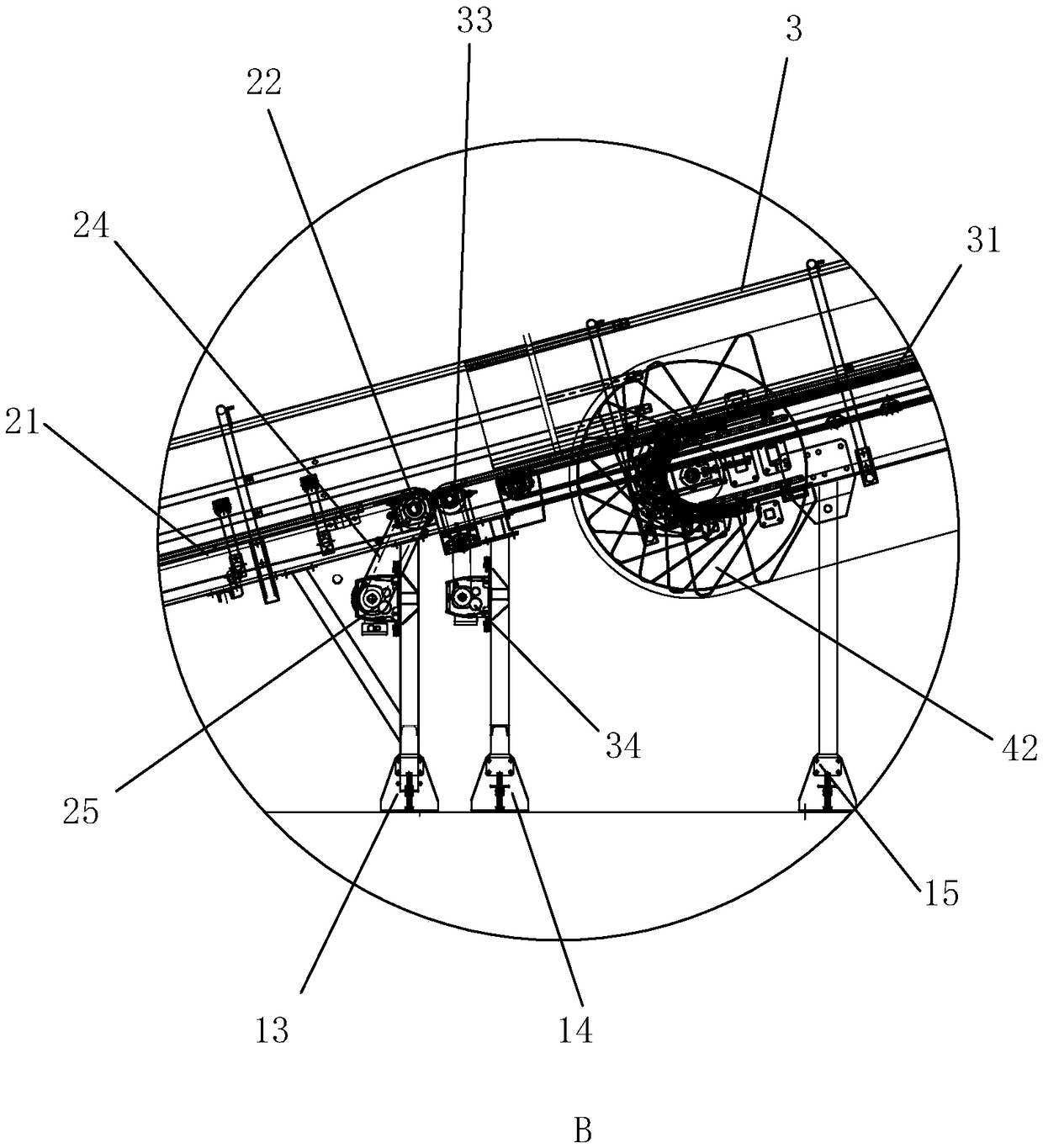

[0011] Such as Figure 1 to Figure 3 As shown, the luggage conveying device of the present invention includes a bracket 10 , a primary conveying belt 20 , a secondary conveying belt 30 , a tertiary conveying chain 40 and a connecting chute 50 . The primary conveyor belt 20 , the secondary conveyor belt 30 , the tertiary conveyor chain 40 and the connecting chute 50 are all fixed and supported by the bracket 10 . Around the upper ends of the primary conveyor belt 20, the secondary conveyor belt 30, and the tertiary conveyor chain 40, a protective frame 3 is installed, and the protective frame 3 is fixed on the support 10. The protective frame 3 and the primary conveyor belt 20, the secondary conveyor belt 30 and the A transport channel is formed between the stage conveyor chains 40, and the transport channel is an irregular serpentine inclined upward slope transport channel, through which the luggage case O is upwardly transported. delivery.

[0012] Such as Figure 1 to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com