Spinning machine with high safety

A high-safety, textile machine technology, applied in the direction of continuous winding spinning machine, textile, loom, etc., can solve the problems of poor versatility, adaptation, damage of anti-pinch device, etc. Good performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

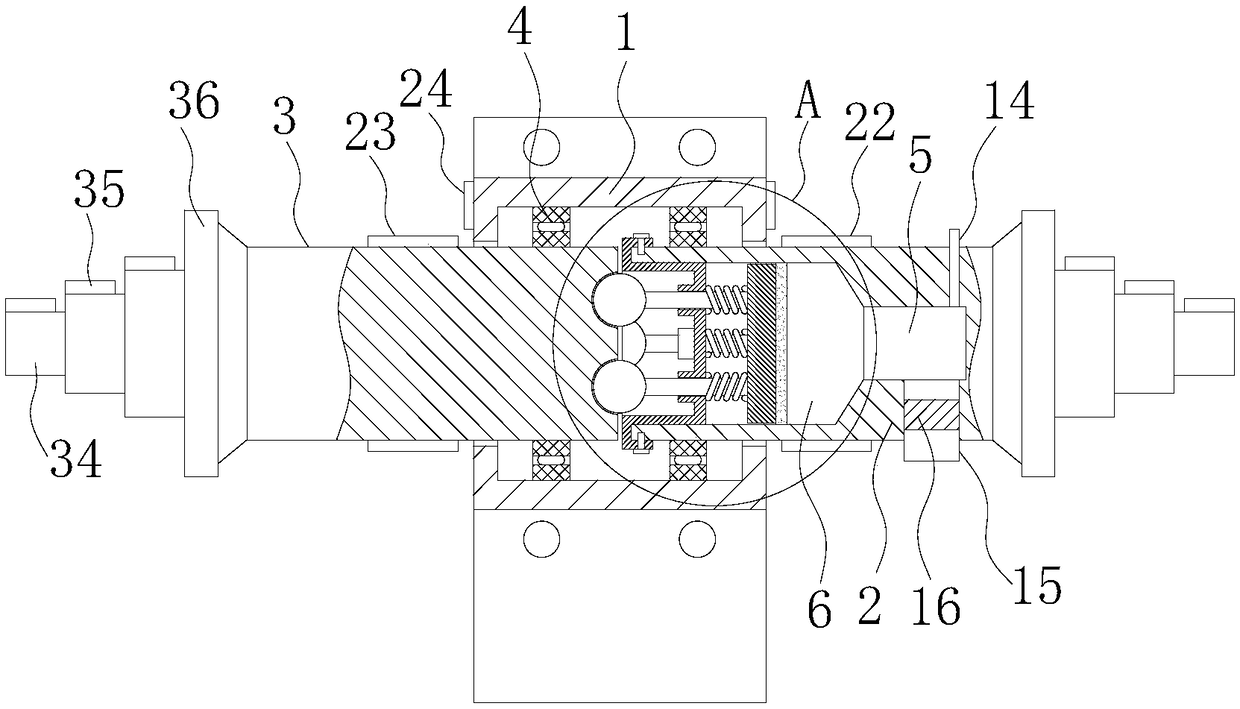

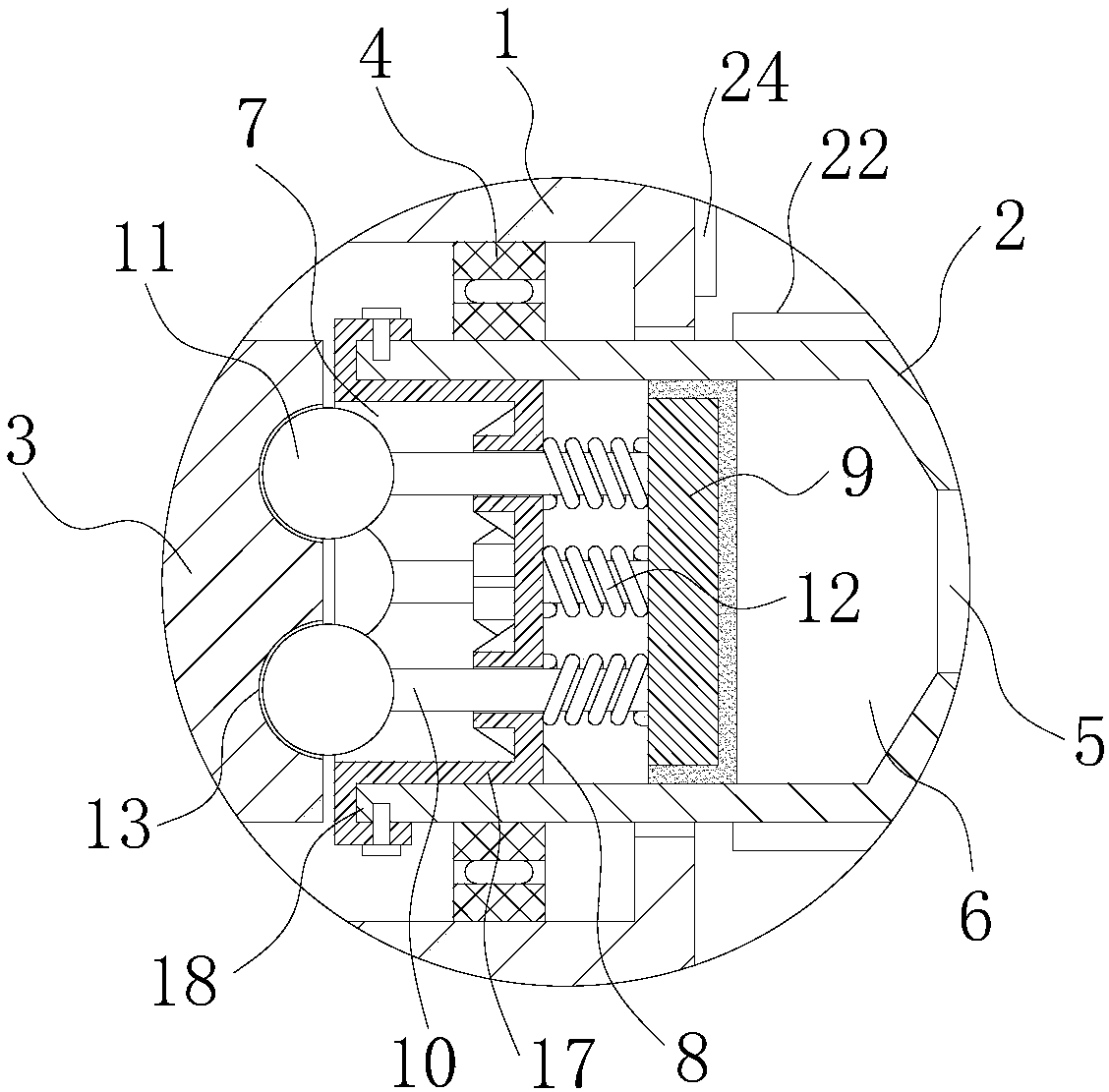

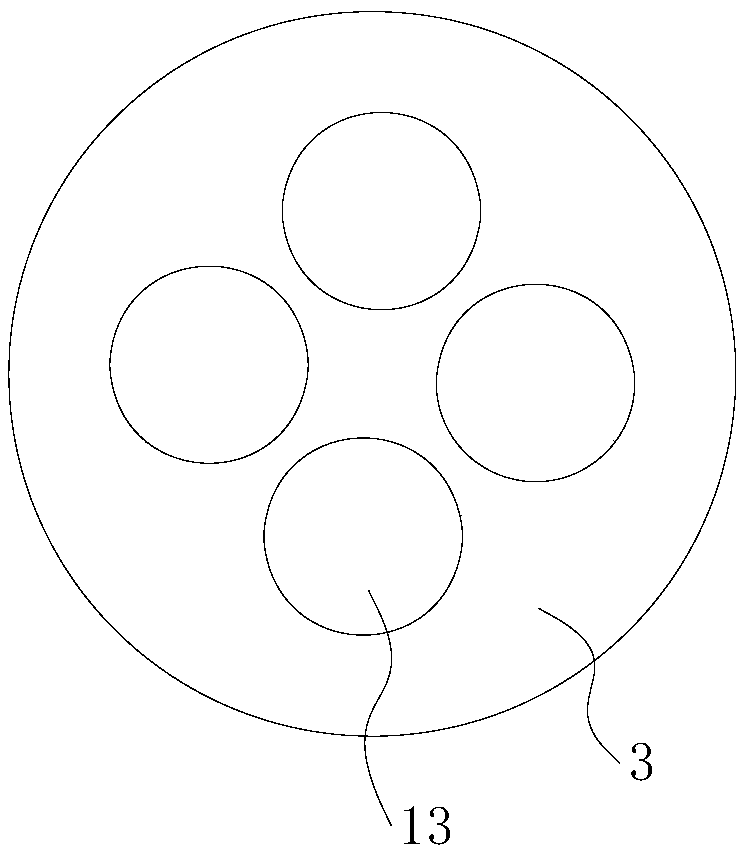

[0024] like Figure 1-6 A textile machine with high safety is shown, the power transmission path between the prime mover and the shaft of the textile machine is provided with an anti-pinch device, and the prime mover can be an oil extraction machine, a gasoline engine, an electric motor, etc. , generally using a motor; the shaft is the shaft that uses power, such as the conveyor shaft, reel, wheel shaft, etc. of the textile machine. The anti-pinch device of the present invention is used to connect the motor and the shaft, transmit the power of the motor to the shaft, and perform abnormal protection. like figure 1 As shown, the anti-pinch device includes a mounting base 1 and a main shaft 2 and a sub shaft 3 with opposite ends. The mounting seat 1 is in the shape of a sleeve, which is set on the opposite side of the main shaft 2 and the auxiliary shaft 3, and is respectively connected with the main shaft 2 and the auxiliary shaft 3 through the bearing 4, and the opposite ends...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com