The Method of Removing Cone Slope of Ribbed Abutment in Road Operation State

A technology of operating status and cone slope, applied in the direction of roads, roads, bridges, etc., can solve the problems of road interruption, insufficient work space, poor adaptability, etc., and achieve the effect of avoiding high risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

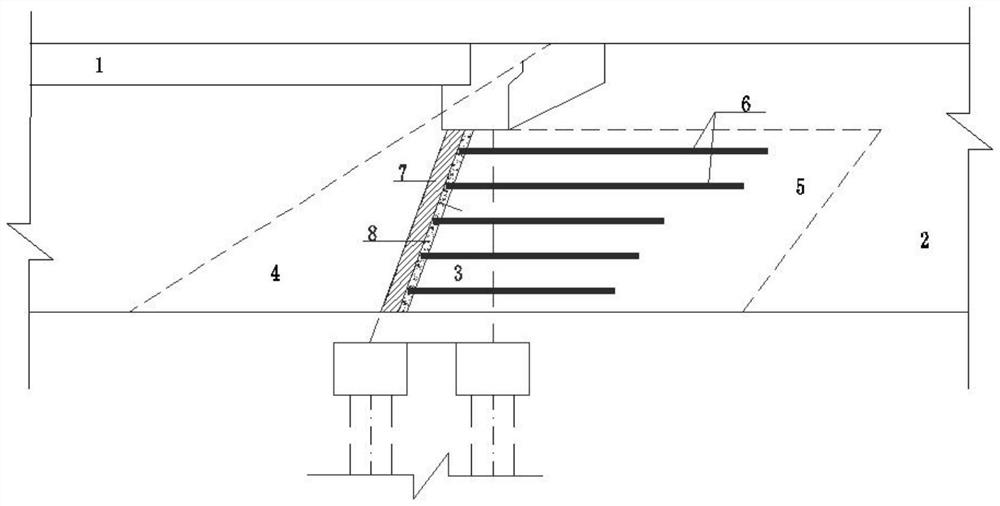

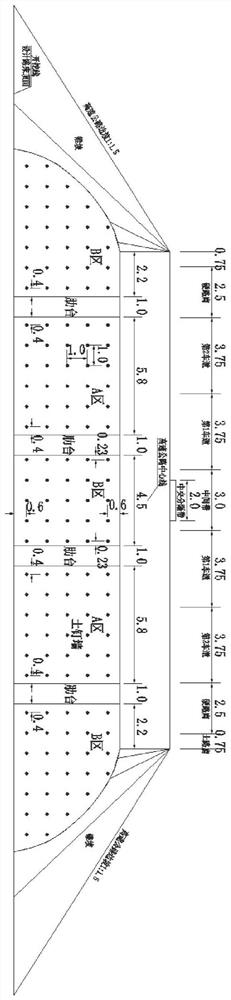

[0032] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] The present invention combines the following three technical measures to make the soil nail support, rib platform and panel form an integral support structure after the cone slope is removed, such as figure 1 As shown, bearing the earth pressure behind the abutment ensures the safety of the rib abutment cone slope removal during construction and permanent use, making this technology feasible and avoiding the large construction or use risks caused by demolition and reconstruction of bridges. , high cost, long construction period, large resource consumption, and large impact on operations.

[0034] (1) Pre-reinforce the soil within a certain range in front of the excavation face of the tapered slope by grouting. After grouting, a certain range of rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com