Dam stilling pool prefabricated gallery crowned arch steel template

A steel formwork and formwork technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of difficult work, small safety factor, inconvenient construction, etc., and achieve the effect of convenient production, low cost and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

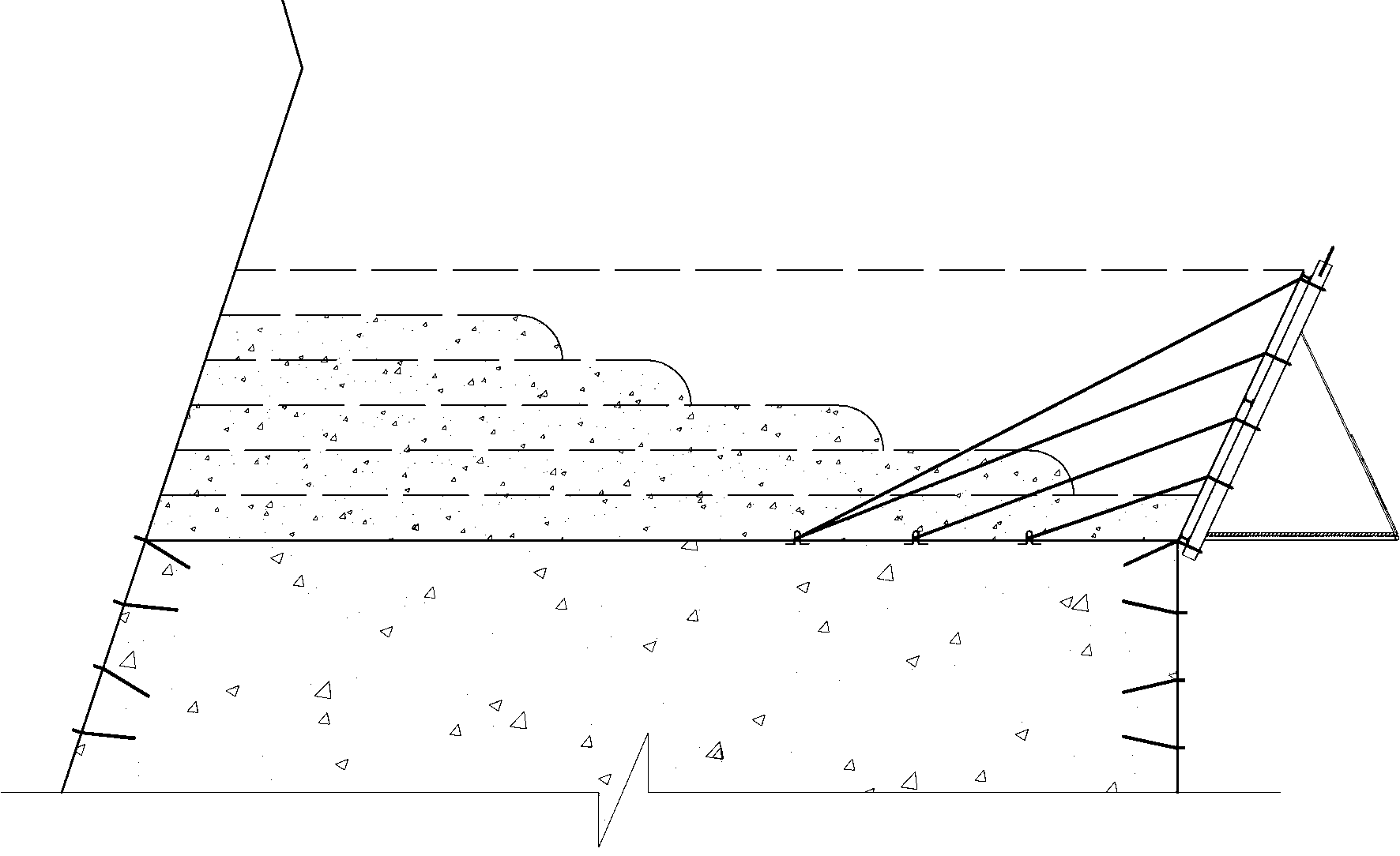

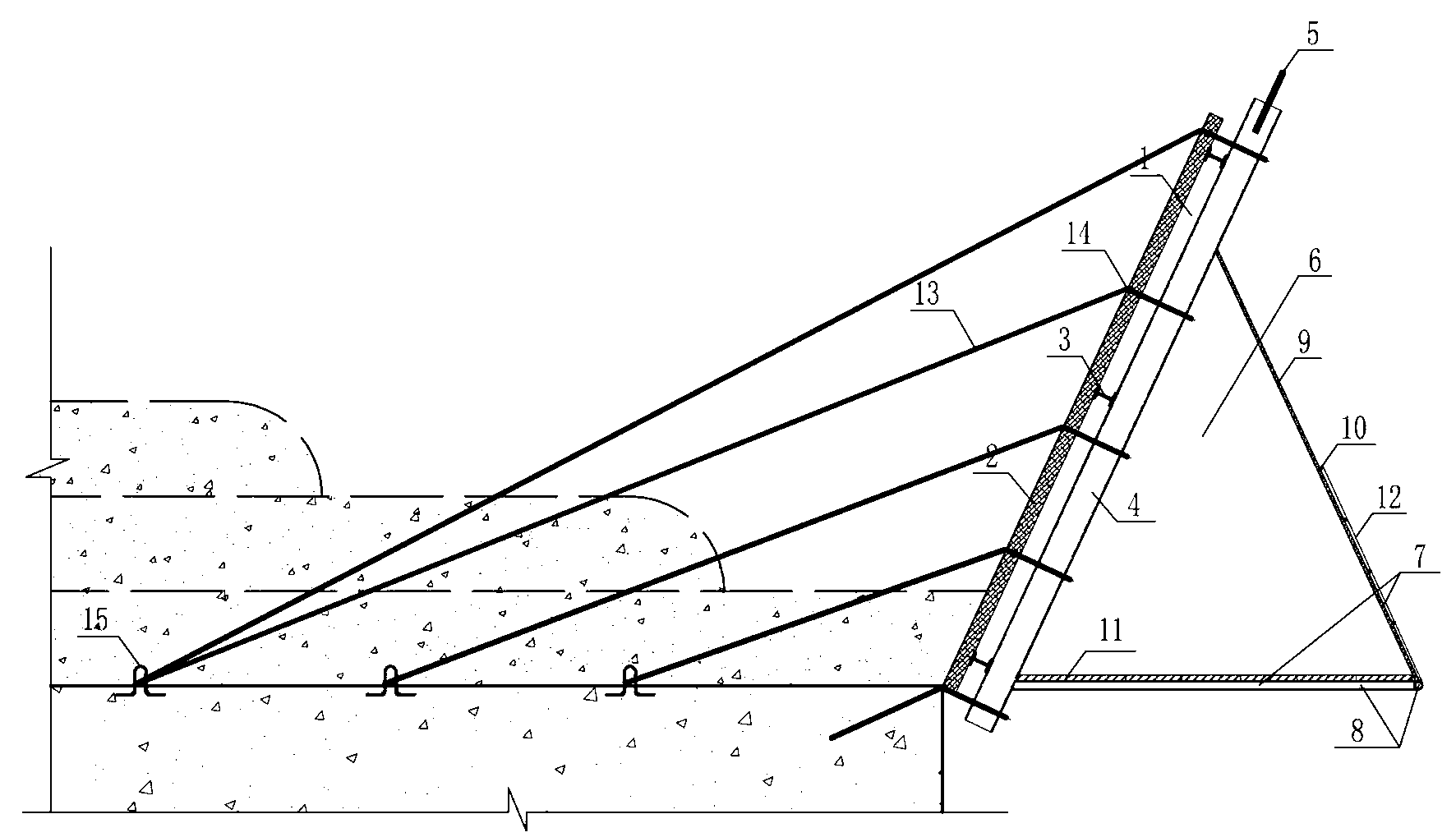

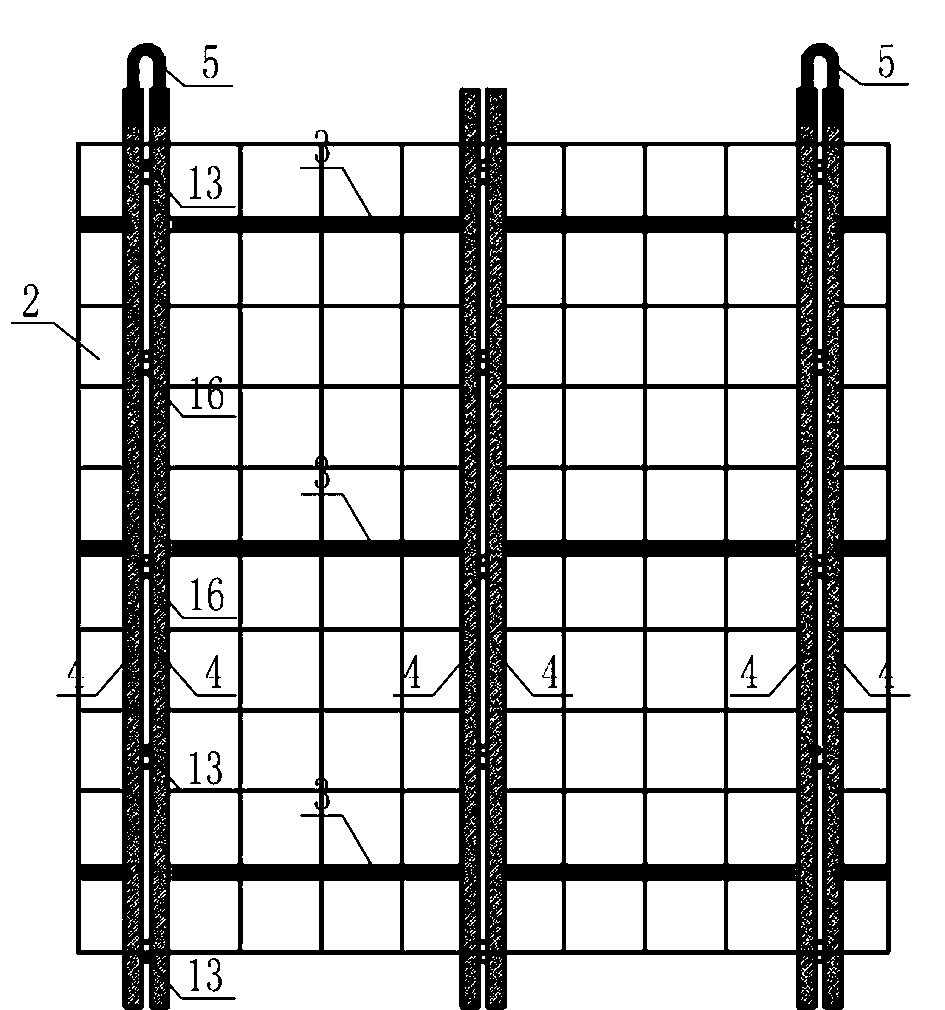

[0017] The structure of the present invention is as figure 1 As shown in -4, a combined cantilever formwork for pouring the inclined part of the dam, the combined cantilever formwork for pouring the inclined part of the dam includes a combined steel formwork 1 and a safety work platform 6, and the combined steel formwork 1 includes a steel formwork 2, a transverse rib 3 and a longitudinal rib 4, and the steel formwork 1 is provided with a brace hole 14 for connecting the template brace 15, and the brace 15 is connected to the steel formwork 1 through the bolt on the brace hole 14, The transverse rib 3 is fixed on the back of the steel formwork 1 , and the longitudinal rib 4 is fixed on the transverse rib 3 ; the safe working platform 6 is composed of a bracket 7 and a safety net 12 .

[0018] The support 7 includes cross braces 8 and vertical braces 9 connected to each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com