Processing method and processing device for implant material having excellent biocompatibility

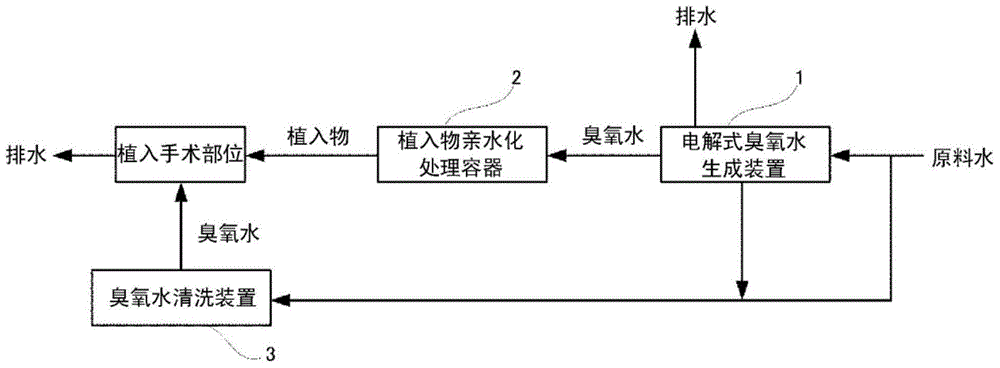

A technology for implant materials and processing methods, which is applied in the field of processing methods and devices for dental implant materials, can solve problems such as undisclosed, unclear titanium surface degradation, and difficulty in manufacturing date of implant materials, so as to ensure safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

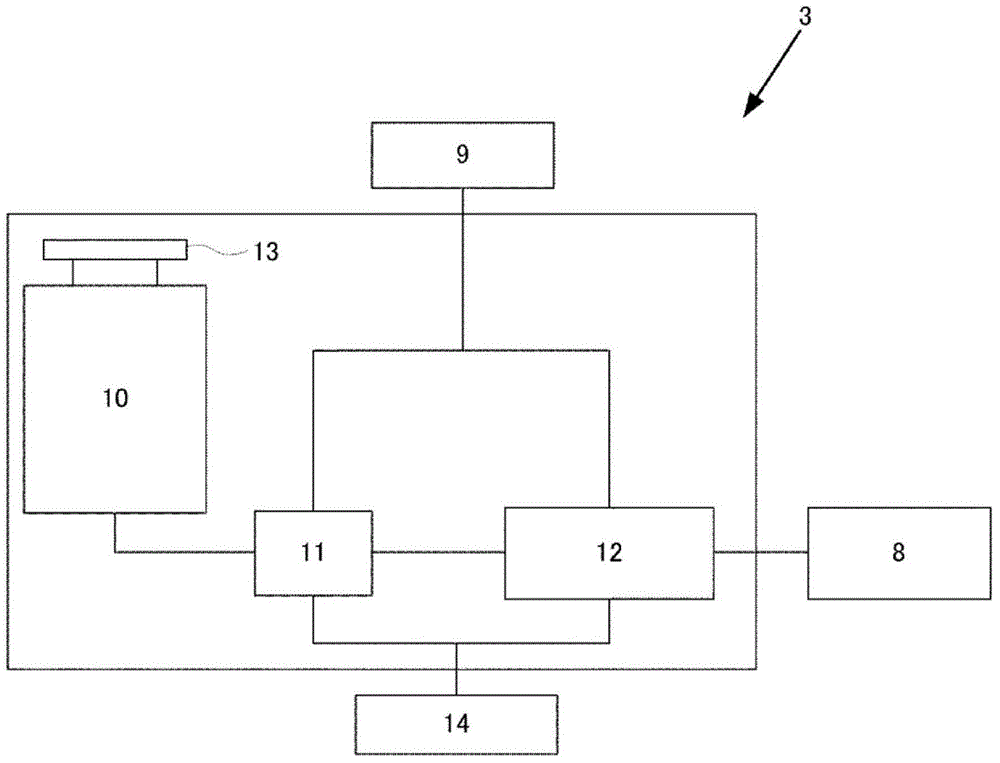

Method used

Image

Examples

Embodiment

[0115] Examples of the present invention are shown below.

[0116]

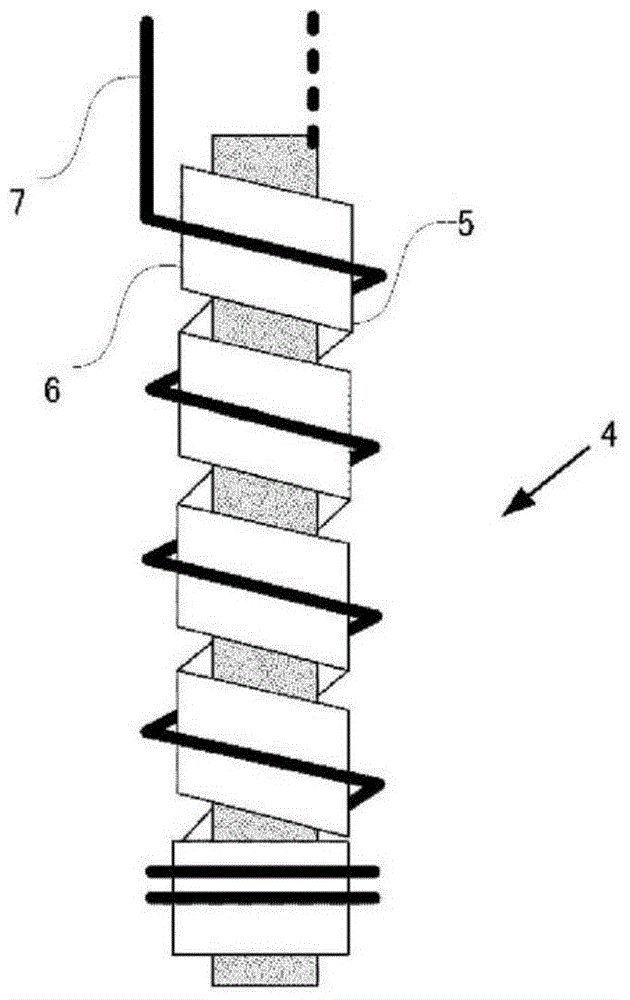

[0117] A cylindrical ion-exchange membrane (Nafion350, thickness 0.35 mm, diameter 3 mm) (Nafion is a registered trademark of DU PONT Co., Ltd.) is wound spirally on a niobium rod-shaped (diameter 2 mm) anode (formed with a conductive diamond catalyst ( The doping concentration of boron is 2500ppm)), and a platinum wire is wound on the separator to form an anode-membrane-cathode assembly. Pure water was flowed in at a rate of 40 mL per minute from the lower part of the electrolytic cell to which this membrane-electrode assembly was mounted. A current of 0.5A was passed, and as a result, due to the spiral diaphragm, oxygen, ozone, and hydrogen generated from the anode were mixed to generate electrolyzed water in which they were dissolved. The battery voltage at this time was 10V, and ozone water The concentration is 4ppm.

[0118] The surface of a titanium disc with a diameter of 8 mm and a thickness of 1 ...

Embodiment 2

[0123] Put the niobium rod-shaped (diameter 2mm) anode (formed with a conductive diamond catalyst (boron doping concentration 2500ppm)) into a cylindrical ion-exchange membrane (Nafion350 manufactured by DU PONT Co., Ltd., thickness 0.35mm, diameter 3mm); As the cathode, a commercially available platinum wire (diameter: 0.4 mm) was spirally wound on the membrane to form an anode-membrane-cathode assembly. The spacing of the spirals is 4 mm. Tubes (diameter 4 mm) were bonded to the upper and lower sides of the junction, and the power supply lines of the electrodes were connected from a DC power supply to form an electrolytic cell, and pure water was flowed in at 40 mL per minute from the lower part of the anode chamber. A current of 1A was passed, and as a result, the battery voltage at this time was 19V, and the concentration of ozone water was 21ppm.

[0124] The same test as in Example 1 was carried out. As a result, carbon compounds on the titanium surface were reduced by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com