Method for installing and adjusting optical axis of despinning part of Pechan prism

The technology of a Biechan prism and its installation and adjustment method is applied in the field of installation and adjustment of the optical axis of the derotation part of the Biechan prism, which can solve the problems of increased workload, human eye error, difficulty, and inability to monitor and adjust in real time, so as to save debugging time, Avoid the effects of blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

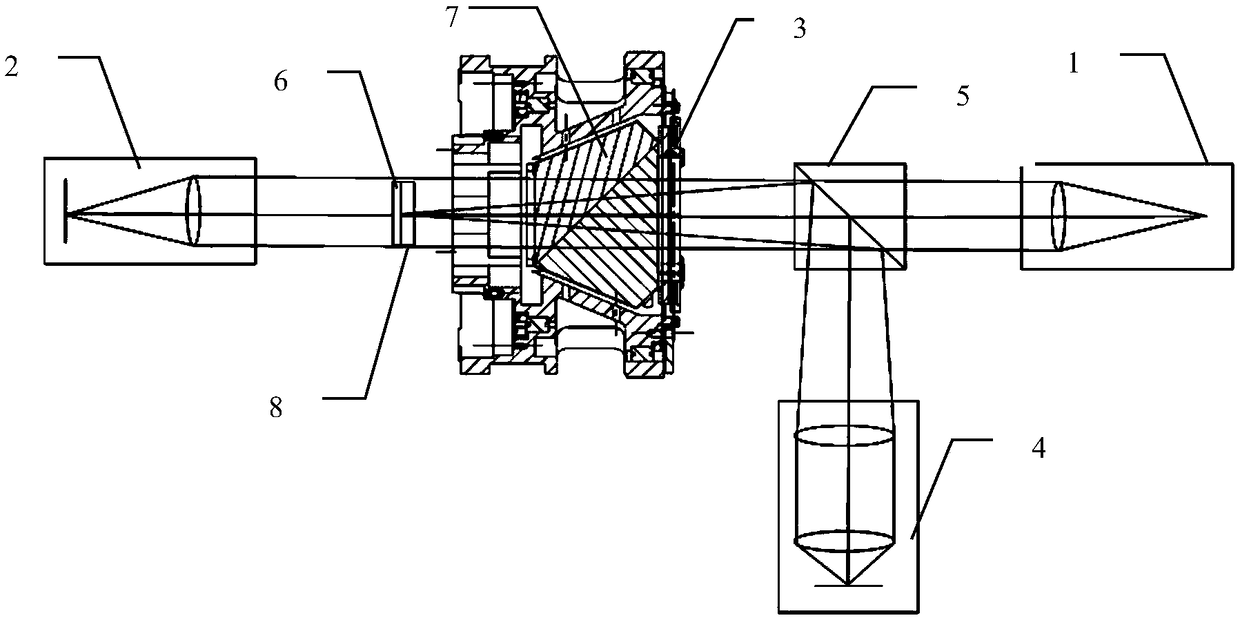

[0021] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0022] Step 1: Align the first photoelectric autocollimator 1 with the second photoelectric autocollimator 2, then place the right-angle beam splitter 5 between the two autocollimators, and adjust the position of the right-angle prism to make the second photoelectric autocollimator 2 pairs of right-angle prism right-angle side self-collimation of the collimator;

[0023] Step 2: Place the inner focusing light pipe in the refraction light path of the right-angle beamsplitter prism 5, adjust the focal length of the inner focusing light pipe 4 to make it image an infinite target, and adjust the position of the inner focusing light pipe so that it is in line with the second photoelectric self- The collimator 2 is mutually aligned. At this time, the optical path composed of the second photoelectric autocollimator 2 and the inner focusing light pipe 4 is parallel to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com