Chia seed high-fiber protein bars and preparation method thereof

A chia seed and high-fiber technology, which is applied in the field of chia seed high-fiber protein bar and its preparation, can solve the problem of single nutritional components of the protein bar, and achieve the effects of improving nutritional value, good moisturizing performance, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

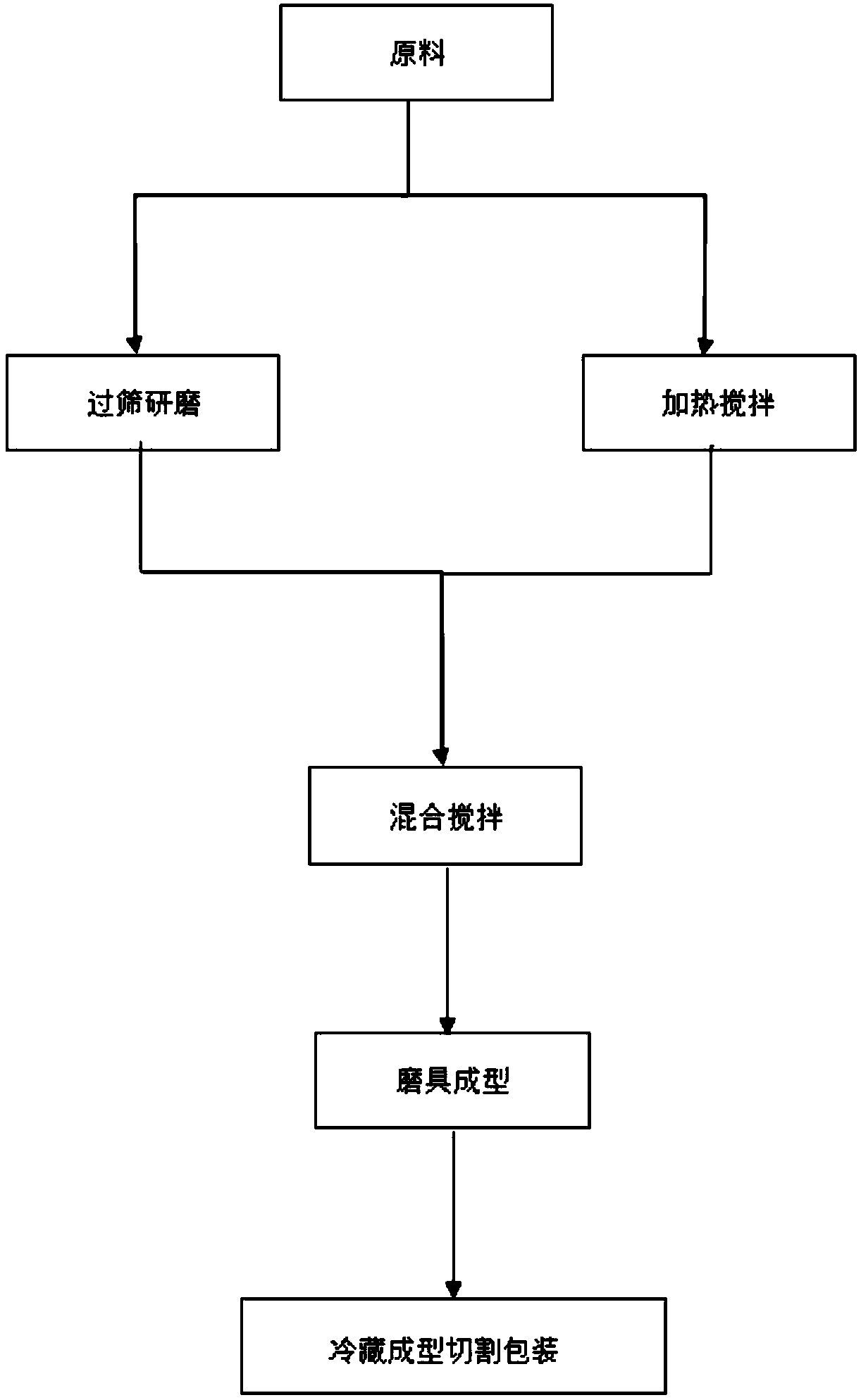

Method used

Image

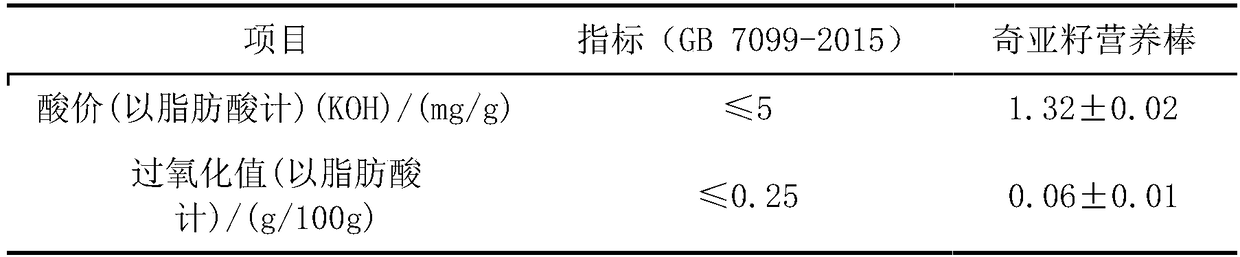

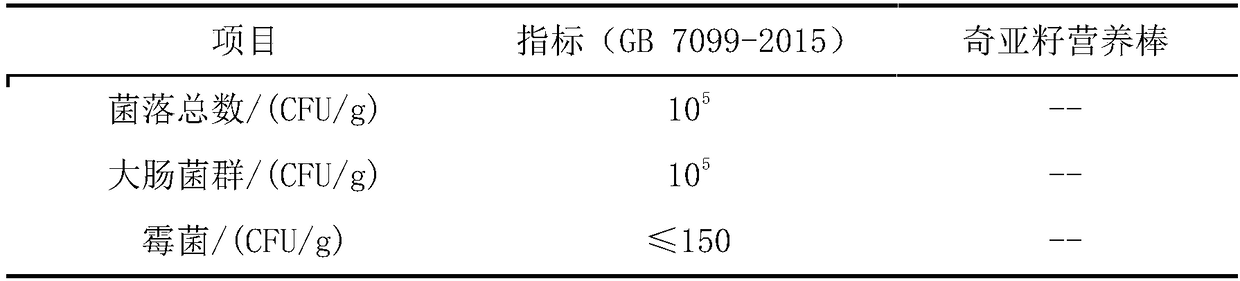

Examples

Embodiment 1

[0025] (1) preparing chia seed cake and chia seed oil by cold pressing chia seeds, and pulverizing the chia seed cake;

[0026] (2) Pass 48 parts of chia seed cake, 10 parts of Fonterra New Zealand Whey Protein Concentrate WPC80, 3 parts of sodium caseinate, and 4 parts of carrageenan through a 40-mesh sieve; pour into a clean container and mix for 10 minutes until Uniform, made into composite powder material;

[0027] (3) Heat 20 parts of maltitol liquid, 6 parts of glycerin, 4 parts of shortening, and 5 parts of chia seed oil at 90°C and stir for 10 minutes and stir evenly. Pour the evenly stirred liquid into a blender , stirring at high speed for 10 minutes to emulsify;

[0028] (4) Pour the composite powder material into a mixer, and stir until the material is whipped into loose and uniform material particles;

[0029] (5) Spread the material particles in batches into the molding die for extrusion molding;

[0030] (6) Put the molded semi-finished nutrition bar into a z...

Embodiment 2

[0039] (1) preparing chia seed cake and chia seed oil by cold pressing chia seeds, and pulverizing the chia seed cake;

[0040] (2) Pass 47 parts of chia seed cake, 9 parts of Fonterra New Zealand Whey Protein Concentrate WPC80, 3 parts of sodium caseinate, and 4 parts of carrageenan through a 40-mesh sieve; pour into a clean container and mix for 10 minutes until Uniform, made into composite powder material;

[0041] (3) Heat 19 parts of maltitol liquid, 6 parts of glycerin, 4 parts of shortening, and 5 parts of chia seed oil at 95°C and stir for 8 minutes and stir evenly. Pour the evenly stirred liquid into a blender , stirring at high speed for 10 minutes to emulsify;

[0042] (4) Pour the composite powder material into a blender, stir until uniform, add 3 parts of crushed nuts, and continue stirring until the material is whipped into loose and uniform material particles;

[0043] (5) Spread the material particles in batches into the molding die for extrusion molding;

...

Embodiment 3

[0046] (1) preparing chia seed cake and chia seed oil by cold pressing chia seeds, and pulverizing the chia seed cake;

[0047] (2) Pass 49 parts of chia seed cake, 8 parts of Fonterra New Zealand Whey Protein Concentrate WPC80, 3 parts of sodium caseinate, and 4 parts of carrageenan through a 40-mesh sieve; pour into a clean container and mix for 10 minutes until Uniform, made into composite powder material;

[0048] (3) Heat 19 parts of maltitol liquid, 5 parts of glycerin, 3 parts of shortening, and 5 parts of chia seed oil at 95°C and stir for 8 minutes and stir evenly. Pour the evenly stirred liquid into a blender , stirring at high speed for 10 minutes to emulsify;

[0049] (4) Pour the composite powder material into a blender, stir until uniform, add 4 parts of fruit grains, and continue stirring until the material is whipped into loose and uniform material particles;

[0050] (5) Spread the material particles in batches into the molding die for extrusion molding;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com