Vertical continuous production equipment for phosphorus pentafluoride

A technology of phosphorus pentafluoride and production equipment, applied in the field of reactors, can solve the problems of inability to maintain consistent contact area, fluctuating reaction rate, unfavorable reaction rate, etc., and achieve the effects of easy transportation, stable reaction, and reduction of safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

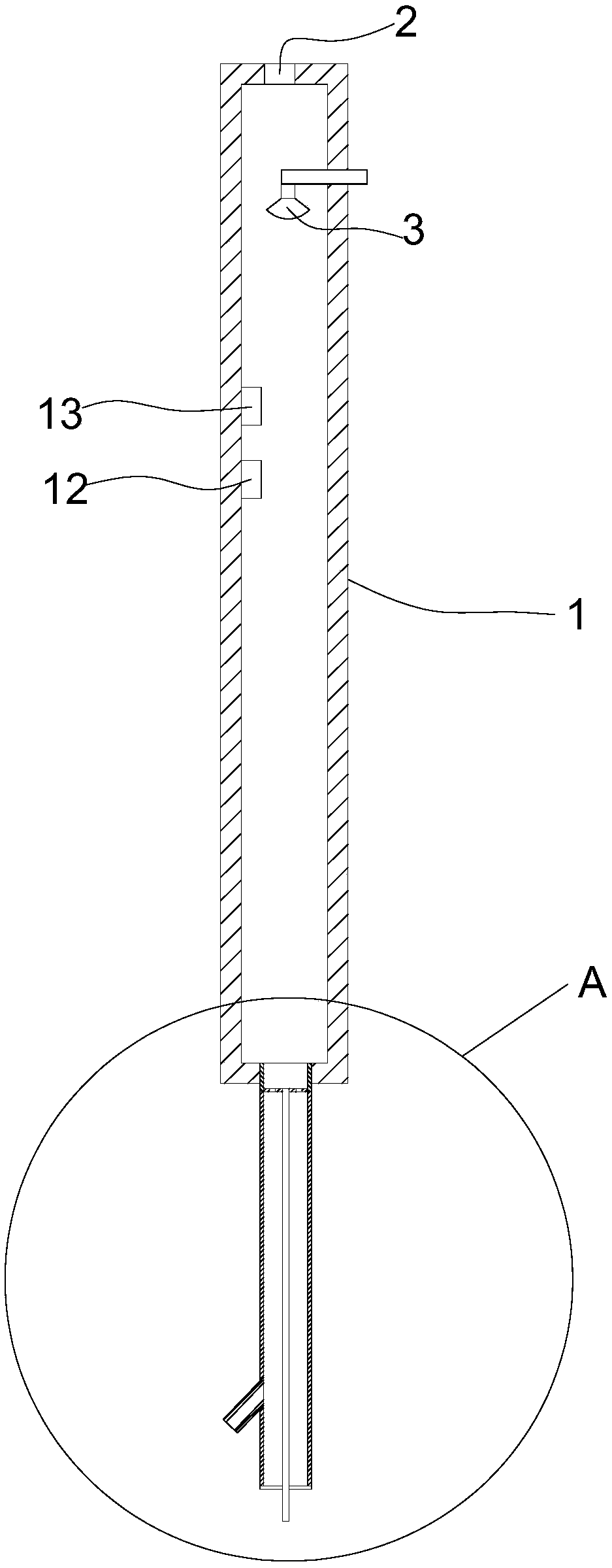

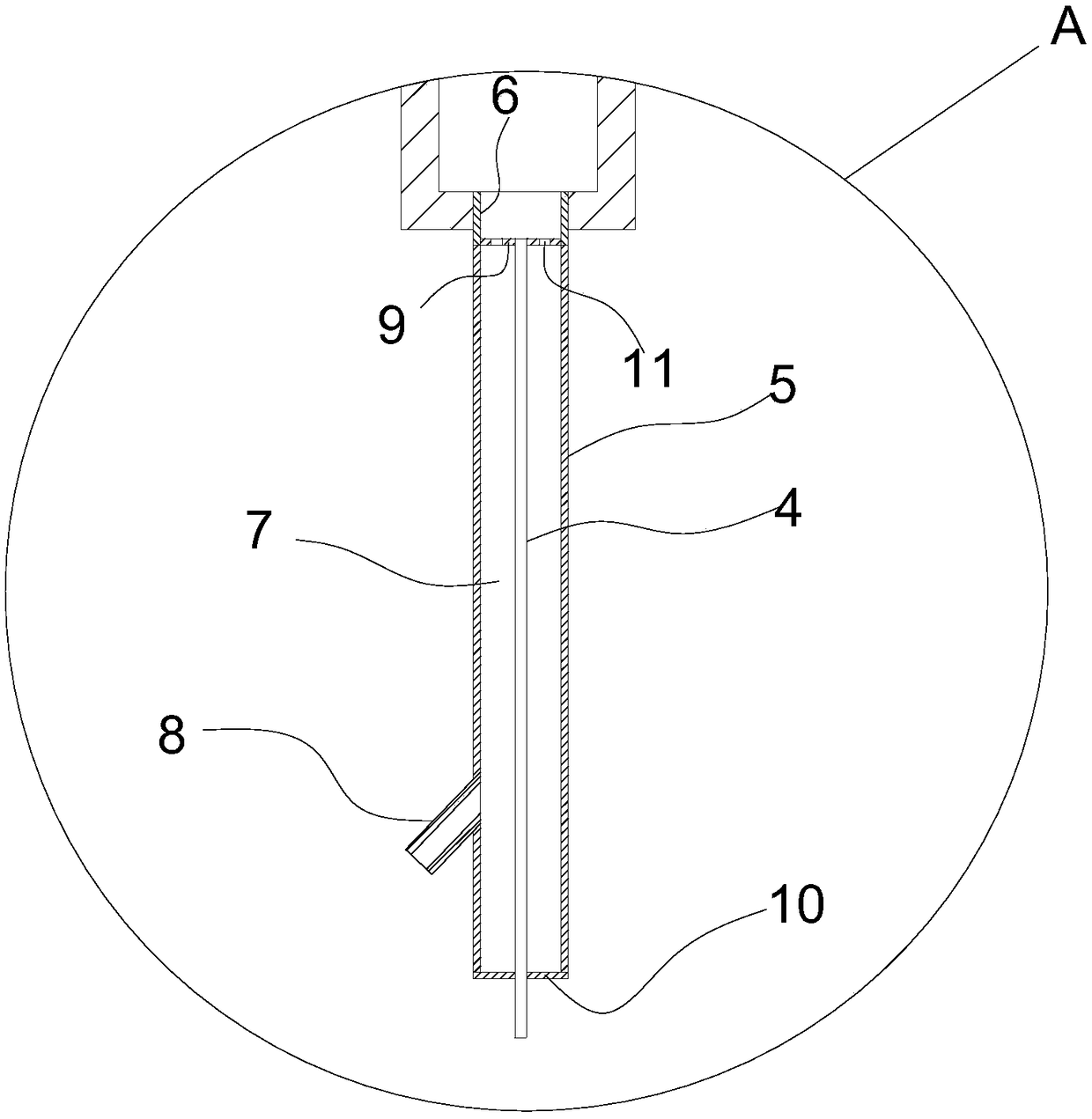

[0018] Such as figure 1 with figure 2 As shown, the vertical continuous production equipment of phosphorus pentafluoride of the present invention comprises a vertical reaction vessel 1, the bottom of the vertical reaction vessel 1 is provided with an air inlet, and the top is provided with an exhaust port 2, and the exhaust port The side wall of the vertical reaction vessel 1 below 2 is provided with an atomizing nozzle 3, and the outlet of the atomizing nozzle 3 faces downward.

[0019] The vertical reaction vessel 1 is made of a material with high temperature resistance and high pressure resistance, the air inlet is used to feed in fluorine gas, the exhaust port 2 is used to discharge the generated phosphorus pentafluoride, and the atomizing nozzle 3 is used to discharge the liquid yellow Phosphorus is atomized and dispersed into fine liquid drople...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com