A kind of unstacking device and unstacking method of multi-layer smoke box

A technology of smoke boxes and boxes, applied in the direction of lifting devices, lifting frames, etc., can solve the problems of reducing the efficiency of destacking, stability and reliability, not being able to form a continuous production line, and reducing the service life of manipulators, etc., to achieve flexible loading methods and simple structures , reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

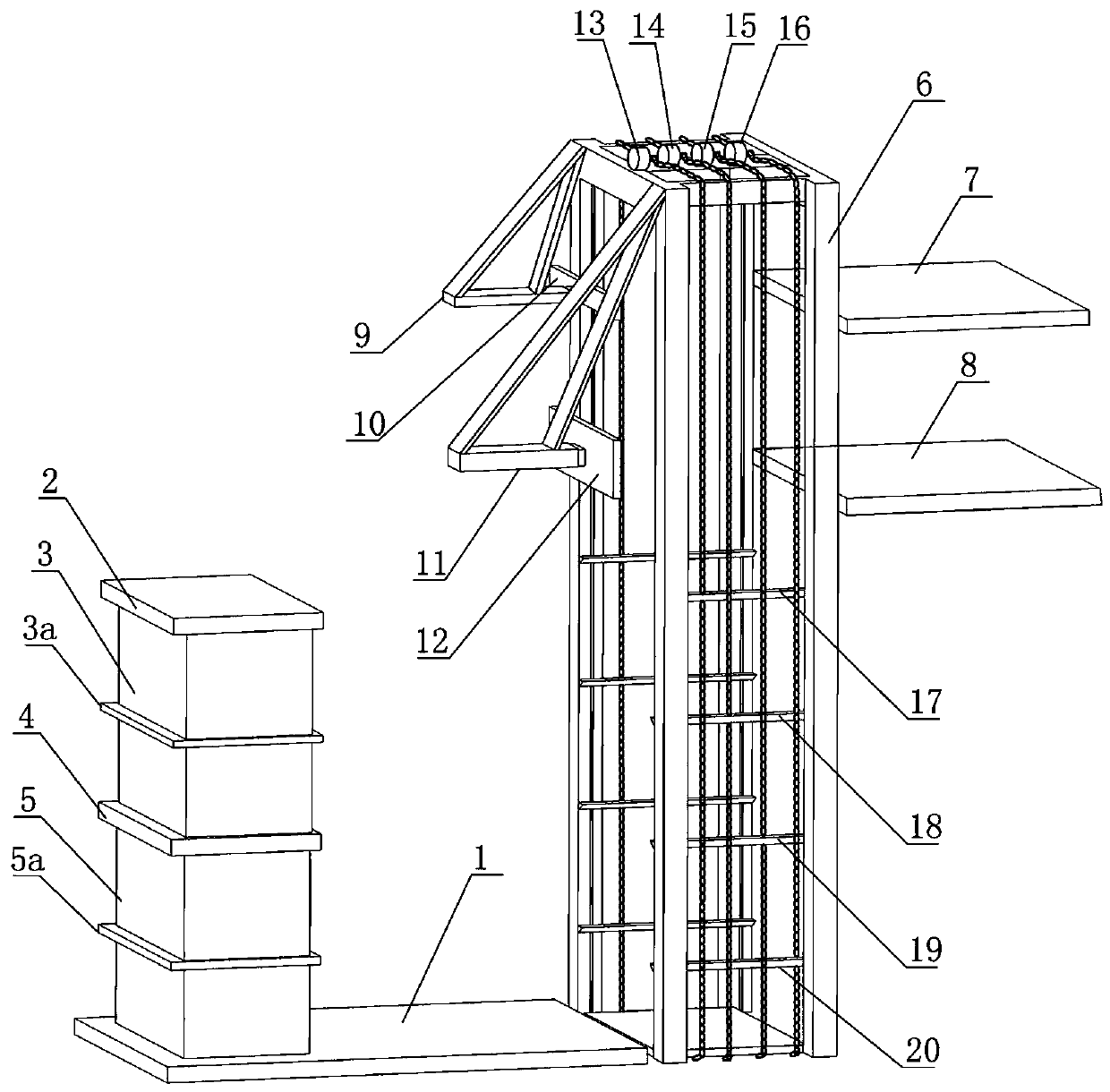

[0036] Such as figure 1 As shown, the present invention includes N layers of smoke boxes, gantry lifting mechanism, smoke box conveying track 1, box cover conveying mechanism and box body conveying mechanism, N≥1, and each layer of smoke boxes includes a box body and a box arranged at the upper end of the box body Cover, the box cover is conveyed to the box cover conveying mechanism by the gantry lifting mechanism, and the box body is conveyed to the box body conveying mechanism by the gantry lifting mechanism;

[0037] The gantry lifting mechanism includes a gantry 6, and N groups of smoke box lifting mechanisms are arranged in the gantry 6 along the vertical direction. The cover lifting mechanism, the box body lifting mechanism and the box cover lifting mechanism are respectively connected to the gantry 6 by sliding up and down;

[0038] The smoke box conveying track 1 is arranged on the left side of the gantry 6, and the right end of the smoke box transporting track 1 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com