Flexible polymer-based PTC material for normal-temperature thermal control, and preparation method thereof

A flexible polymer and warming technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problems that PTC materials cannot be flexible, cannot be thinned, and cannot be practically applied to high-precision temperature control at room temperature. , to achieve the effects of making up for the flexibility and inability to be thinned, good PTC characteristics and flexibility, and simple and feasible preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

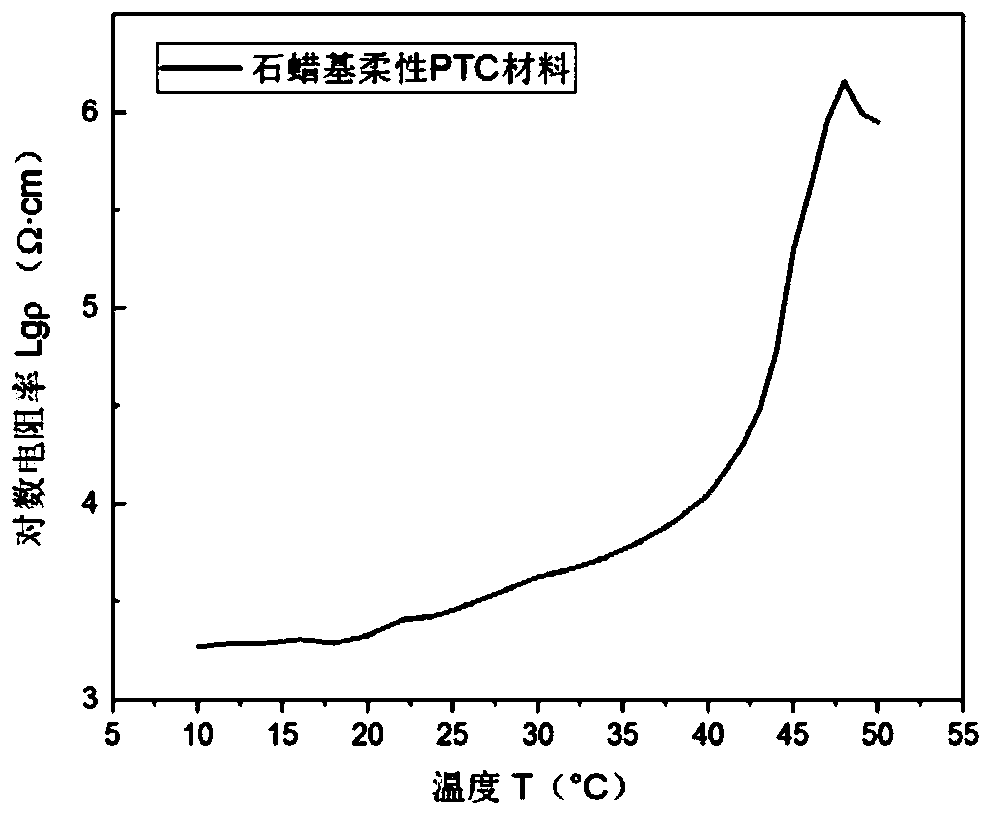

Embodiment 1

[0026] The specific preparation steps of a flexible polymer-based PTC material for thermal control at room temperature are as follows:

[0027] (1) Add 45g of ethylene octene block copolymer (OBC) and 105g of paraffin into the stainless steel kettle body, cover the sealing cover tightly, then put the stainless steel kettle body into a constant temperature oil bath, and connect the vacuum pump through a rubber tube The exhaust port of the stainless steel kettle body is used to evacuate the inside of the kettle body, and stir and mix evenly with a digital constant speed mixer at a temperature of 150-170°C and a speed of 300 rpm;

[0028] (2) Add 100g of graphite powder (GP) again, stir at a speed of 300 rpm at a temperature of 150-170°C under vacuum conditions, stir and mix evenly to obtain a mixture;

[0029] (3) Press the mixed material into a disc sample with a diameter of 30mm and a thickness of 5mm by a hot press, cool to room temperature and set it, and let it stand for 3-...

Embodiment 2

[0035] The specific preparation steps of a flexible polymer-based PTC material for thermal control at room temperature are as follows:

[0036] (1) Add 45g of ethylene octene block copolymer (OBC) and 105g of n-octadecane into the stainless steel kettle body, cover and seal it tightly, then put the stainless steel kettle body into a constant temperature oil bath, and put the vacuum pump through the rubber The pipe is connected to the exhaust port of the stainless steel kettle body, and the inside of the kettle body is vacuumed. Under the conditions of temperature 150-170°C and speed 300 rpm, stir and mix evenly with a digital constant speed mixer;

[0037] (2) Add 100g of graphite powder (GP) again, stir at a speed of 300 rpm at a temperature of 150-170°C under vacuum conditions, stir and mix evenly to obtain a mixture;

[0038] (3) Press the mixed material into a film of 140mm*70mm*0.8mm by a hot press, cool to room temperature and shape it, let it stand for 6-8 hours, and wa...

Embodiment 3

[0041] The specific preparation steps of a flexible polymer-based PTC material for thermal control at room temperature are as follows:

[0042](1) Add 45g of ethylene octene block copolymer (OBC) and 135g of paraffin into the stainless steel kettle body, cover the sealing cover tightly, then put the stainless steel kettle body into a constant temperature oil bath, and connect the vacuum pump through a rubber tube The exhaust port of the stainless steel kettle body is used to evacuate the inside of the kettle body, and stir and mix evenly with a digital constant speed mixer at a temperature of 150-170°C and a speed of 300 rpm;

[0043] (2) Add 20 g of conductive carbon black (CB), and stir at a speed of 300 rpm at a temperature of 150-170° C. under a vacuum condition, and stir and mix evenly to obtain a mixture;

[0044] (3) Press the mixed material into a disc sample with a diameter of 30mm and a thickness of 5mm by a hot press, cool to room temperature and set it, and let it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com