7-series aluminum alloy and preparation method thereof

An aluminum alloy, weight percentage technology, applied in the field of aluminum alloy, to achieve the effect of improving the mechanical properties, improving the strengthening phase of magnesium and zinc, and satisfying the effect of high gloss appearance and sandblasting anode effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

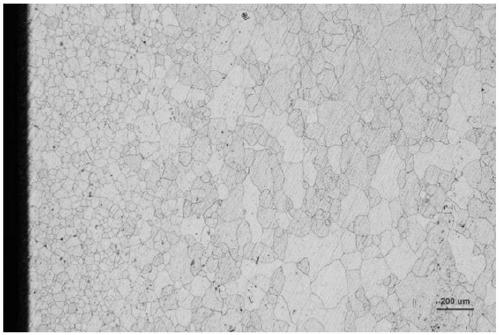

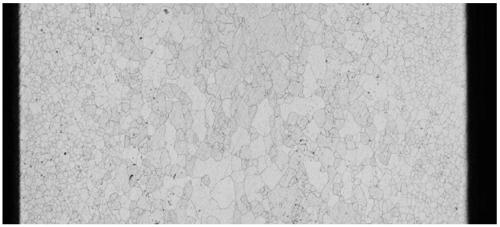

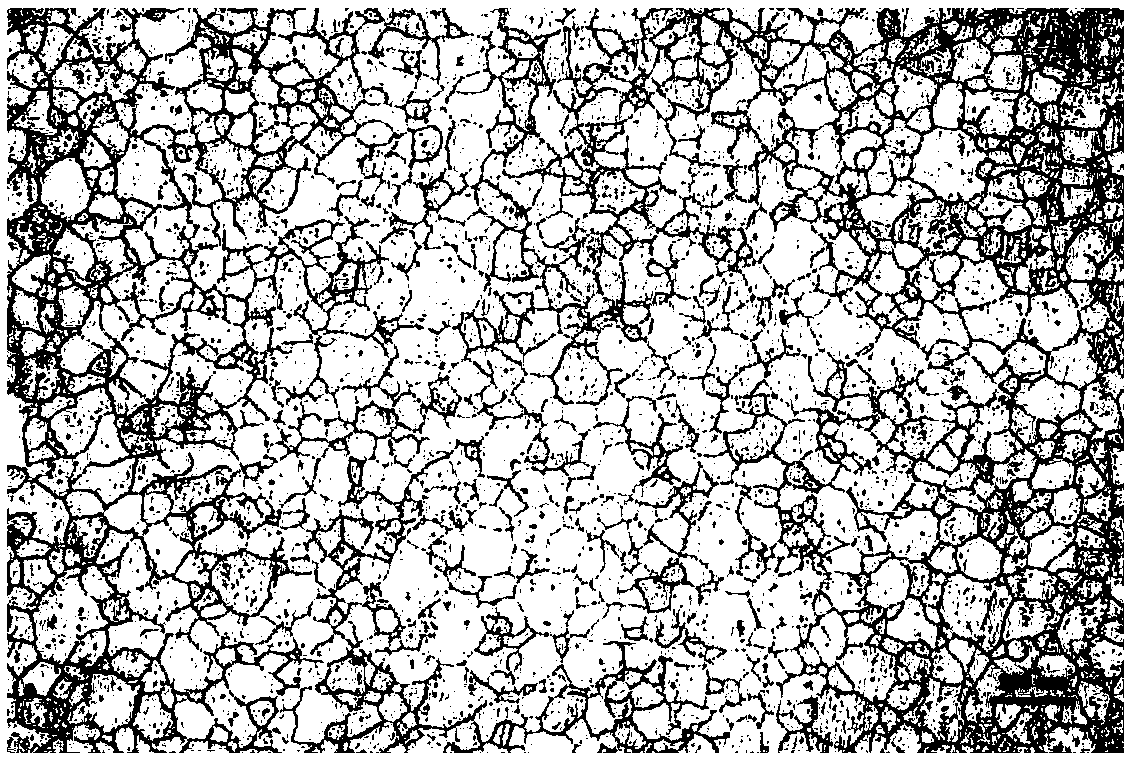

Image

Examples

preparation example Construction

[0029] A method for preparing a 7-series aluminum alloy, which comprises batching, melting and stirring in sequence according to the components of the above-mentioned 7-series aluminum alloy, and adding an intermediate alloy containing rare earth cerium in an amount of 0.01-0.015% by weight to obtain a first melt ; The first melt is subjected to refining for the first time, slag removal for the first time, and standing for the first time in sequence, and the first melt after the first standing is subjected to heat preservation treatment to obtain a second melt; The second melt is sequentially subjected to the second refining, the second slag removal and the second standing to obtain the third melt; the third melt is sequentially subjected to online vacuum degassing, plate filtration and tube filtration purification, Then, semi-continuous oil-air sliding is used for casting under the condition of liquid cavity temperature of 670-690° C., followed by homogenization and cooling tr...

Embodiment 1

[0044] The 7-series aluminum alloy of this embodiment is composed of the following components in weight percentage: 1.95% magnesium, 0.04% silicon, 0.04% iron, 0.15% copper, 0.023% titanium, 5.68% zinc, 0.16% manganese and 0.02% zirconium, balance aluminum.

[0045] In the preparation method of the 7-series aluminum alloy in this embodiment, batching, melting and stirring are carried out sequentially according to the components of the above-mentioned 7-series aluminum alloy, and an intermediate alloy containing rare earth cerium is added in an amount of 0.01% by weight to obtain the first melt ; The first melt is subjected to refining for the first time, slag removal for the first time, and standing for the first time in sequence, and the first melt after the first standing is subjected to heat preservation treatment to obtain a second melt; The second melt is sequentially subjected to the second refining, the second slag removal and the second standing to obtain the third melt;...

Embodiment 2

[0047] The 7 series aluminum alloy of this embodiment is composed of the following components in weight percentage: 2.2% magnesium, 0.1% silicon, 0.06% iron, 0.33% copper, 0.028% titanium, 6.05% zinc, 0.26% manganese and 0.05% zirconium, the balance aluminum.

[0048] In the preparation method of the 7-series aluminum alloy in this embodiment, batching, melting and stirring are carried out in sequence according to the components of the above-mentioned 7-series aluminum alloy, and an intermediate alloy containing rare earth cerium is added in an amount of 0.015% by weight to obtain the first melt ; The first melt is subjected to refining for the first time, slag removal for the first time, and standing for the first time in sequence, and the first melt after the first standing is subjected to heat preservation treatment to obtain a second melt; The second melt is sequentially subjected to the second refining, the second slag removal and the second standing to obtain the third m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com