Preparation method of titanium-coated aluminum-based beta-PbO2-graphene composite electrode

A graphene composite, titanium-clad aluminum technology, used in electrodes, electrolytic coatings, electrolytic processes, etc., to achieve strong stability and electrical conductivity, improve corrosion resistance and electrocatalytic activity, and improve mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

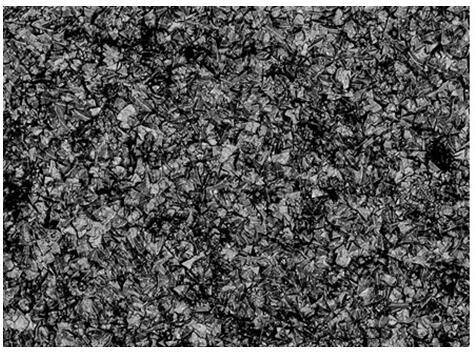

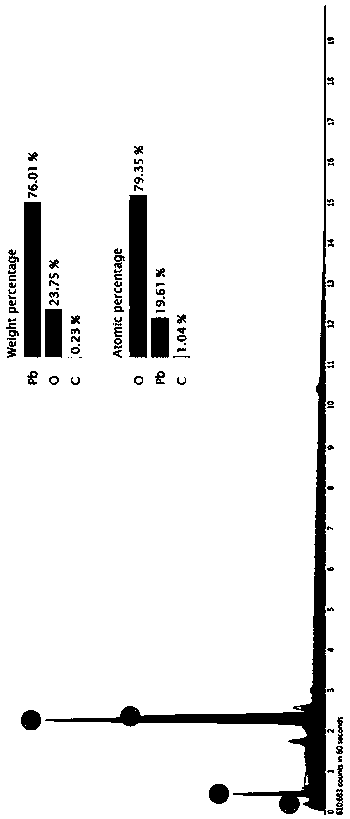

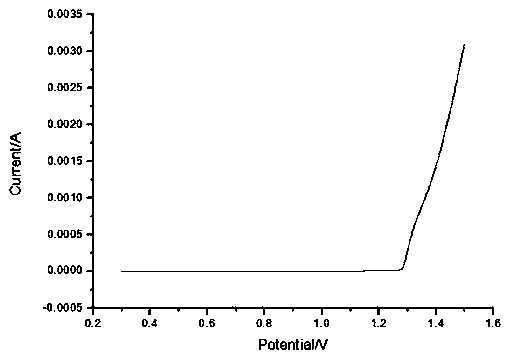

Image

Examples

Embodiment 1

[0032] Example 1: A titanium-clad aluminum-based β-PbO 2 -The preparation method of graphene composite electrode, concrete steps are as follows:

[0033] (1) Add graphene to H 2 SO 4 -HNO 3 -H 2 o 2 - In the mixed acid solution of high potassium sulfate, the temperature is 50 ° C under mechanical stirring for 60 minutes; then ultrasonic stripping is carried out for 120 minutes to obtain nano-graphene; wherein H 2 SO 4 -HNO 3 -H 2 o 2 - H in high potassium sulfate mixed acid solution 2 SO 4 At a concentration of 9 mol / L, HNO 3 Concentration is 3 mol / L, H 2 o 2 The mass fraction is 10%, the concentration of high potassium sulfate is 1mol / L; the thickness of graphene is 10~12nm, the conductivity is 850~950S / m, graphene and H 2 SO 4 -HNO 3 -H 2 o 2 -The solid-to-liquid ratio g:mL of high potassium sulfate mixed acid solution is 1:5;

[0034] (2) Clean the nano-graphene in step (1), then add it to sodium borohydride solution for reduction for 15 minutes to obtain...

Embodiment 2

[0040] Example 2: A titanium-clad aluminum-based β-PbO 2 -The preparation method of graphene composite electrode, concrete steps are as follows:

[0041] (1) Add graphene to H 2 SO 4 -HNO 3 -H 2 o 2 - In the mixed acid solution of high potassium sulfate, mechanical stirring was carried out at a temperature of 60°C for 80 minutes; then ultrasonic stripping was carried out for 60 minutes to obtain graphene nanometers; wherein H 2 SO 4 -HNO 3 -H 2 o 2 - H in high potassium sulfate mixed acid solution 2 SO 4 The concentration is 10mol / L, HNO 3 Concentration is 4mol / L, H 2 o 2 The concentration is 15%, the concentration of high potassium sulfate is 2mol / L; the thickness of graphene is 11~13nm, the conductivity is 950~1050 S / m, graphene and H 2 SO 4 -HNO 3 -H 2 o 2 -the solid-to-liquid ratio g:mL of high potassium sulfate mixed acid solution is 1:3;

[0042] (2) Clean the nano-graphene in step (1), then add it to sodium borohydride solution for reduction for 20 mi...

Embodiment 3

[0047] Example 3: A titanium-coated aluminum-based β-PbO 2 -The preparation method of graphene composite electrode, concrete steps are as follows:

[0048] (1) Add graphene to H 2 SO 4 -HNO 3 -H 2 o 2 - In the mixed acid solution of high potassium sulfate, the temperature is 80 ° C under mechanical stirring for 120 min; then ultrasonic stripping is carried out for 80 min to obtain nano-graphene; wherein H 2 SO 4 -HNO 3 -H 2 o 2 - H in high potassium sulfate mixed acid solution 2 SO 4 The concentration is 13mol / L, HNO 3 Concentration is 5 mol / L, H 2 o 2 The mass percentage is 30%, the concentration of high potassium sulfate is 3 mol / L; the thickness of graphene is 10~14 nm, the conductivity is 850~950 S / m, graphene and H 2 SO 4 -HNO 3 -H 2 o 2 -the solid-to-liquid ratio g:mL of high potassium sulfate mixed acid solution is 1:5;

[0049] (2) Clean the nano-graphene in step (1), then add it to sodium borohydride solution for reduction for 20 minutes to obtain r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com