A titanium-clad aluminum-based β-pbo 2 -Preparation method of graphene composite electrode

A graphene composite, titanium-clad aluminum technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., to achieve the effect of improving corrosion resistance and electrocatalytic activity, improving mechanical strength, strong stability and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

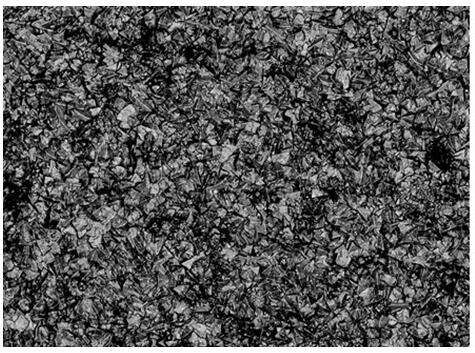

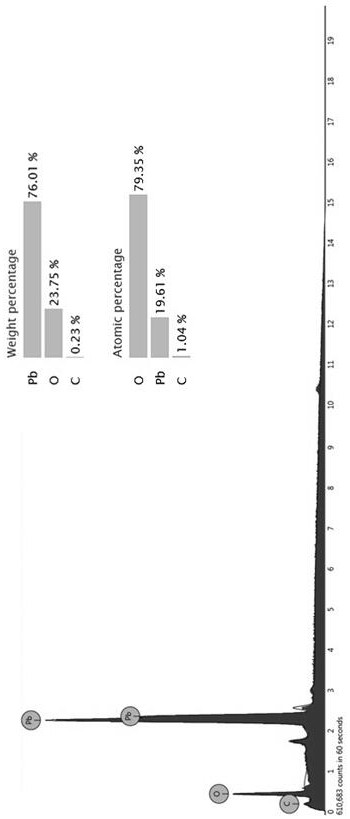

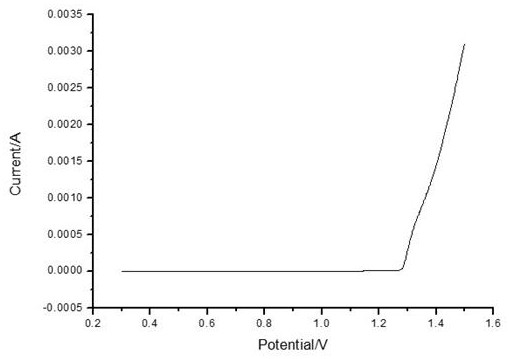

[0032] Example 1: A titanium-clad aluminum-based β-PbO 2 -The preparation method of graphene composite electrode, concrete steps are as follows:

[0033] (1) Add graphene to H 2 SO 4 -HNO 3 -H 2 o 2 - In the mixed acid solution of high potassium sulfate, the temperature is 50 ° C under mechanical stirring for 60 minutes; then ultrasonic stripping is carried out for 120 minutes to obtain nano-graphene; wherein H 2 SO 4 -HNO 3 -H 2 o 2 - H in high potassium sulfate mixed acid solution 2 SO 4 At a concentration of 9 mol / L, HNO 3 Concentration is 3 mol / L, H 2 o 2 The mass fraction is 10%, the concentration of high potassium sulfate is 1mol / L; the thickness of graphene is 10~12nm, the conductivity is 850~950S / m, graphene and H 2 SO 4 -HNO 3 -H 2 o 2 -The solid-to-liquid ratio g:mL of high potassium sulfate mixed acid solution is 1:5;

[0034] (2) Clean the nano-graphene in step (1), then add it to sodium borohydride solution for reduction for 15 minutes to obtain...

Embodiment 2

[0040] Example 2: A titanium-clad aluminum-based β-PbO 2 -The preparation method of graphene composite electrode, concrete steps are as follows:

[0041] (1) Add graphene to H 2 SO 4 -HNO 3 -H 2 o 2 - In the mixed acid solution of high potassium sulfate, mechanical stirring was carried out at a temperature of 60°C for 80 minutes; then ultrasonic stripping was carried out for 60 minutes to obtain graphene nanometers; wherein H 2 SO 4 -HNO 3 -H 2 o 2 - H in high potassium sulfate mixed acid solution 2 SO 4 The concentration is 10mol / L, HNO 3 Concentration is 4mol / L, H 2 o 2 The concentration is 15%, the concentration of high potassium sulfate is 2mol / L; the thickness of graphene is 11~13nm, the conductivity is 950~1050 S / m, graphene and H 2 SO 4 -HNO 3 -H 2 o 2 -the solid-to-liquid ratio g:mL of high potassium sulfate mixed acid solution is 1:3;

[0042] (2) Clean the nano-graphene in step (1), then add it to sodium borohydride solution for reduction for 20 mi...

Embodiment 3

[0047] Example 3: A titanium-coated aluminum-based β-PbO 2 -The preparation method of graphene composite electrode, concrete steps are as follows:

[0048] (1) Add graphene to H 2 SO 4 -HNO 3 -H 2 o 2 - In the mixed acid solution of high potassium sulfate, the temperature is 80 ° C under mechanical stirring for 120 min; then ultrasonic stripping is carried out for 80 min to obtain nano-graphene; wherein H 2 SO 4 -HNO 3 -H 2 o 2 - H in high potassium sulfate mixed acid solution 2 SO 4 The concentration is 13mol / L, HNO 3 Concentration is 5 mol / L, H 2 o 2 The mass percentage is 30%, the concentration of high potassium sulfate is 3 mol / L; the thickness of graphene is 10~14 nm, the conductivity is 850~950 S / m, graphene and H 2 SO 4 -HNO 3 -H 2 o 2 -the solid-to-liquid ratio g:mL of high potassium sulfate mixed acid solution is 1:5;

[0049] (2) Clean the nano-graphene in step (1), then add it to sodium borohydride solution for reduction for 20 minutes to obtain r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com