Dyeing and blow-drying equipment for yarn

A yarn dyeing and equipment technology, which is applied in lighting and heating equipment, textile material processing equipment configuration, liquid/gas/steam yarn/filament processing, etc., can solve the problem of not being able to dye yarns of different colors at the same time, and achieve reduction Labor cost, effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

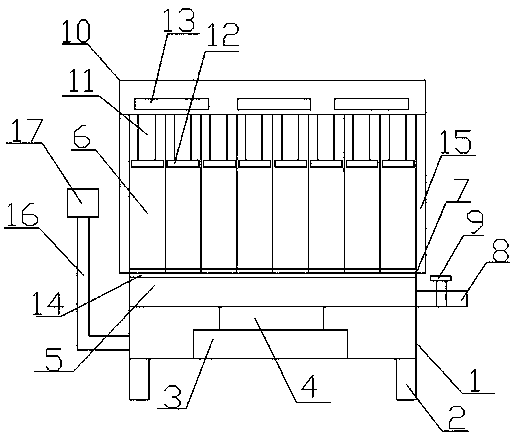

[0013] like figure 1 As shown, the present embodiment provides a yarn dyeing and drying equipment, including a base 1, a universal wheel 2 is provided at the lower end of the base 1, a motor 3 is provided in the middle of the base 1, a motor rod 4 is provided on the motor 3, and a motor rod 4 is provided on the motor 3. The rod 4 is provided with a rotating plate 5, and the rotating plate 5 is provided with dyeing cylinders 6 distributedly. The dyeing cylinder 6 is covered with a housing 7, and the right side of the rotating plate 5 is provided with an outlet pipe 8, and an on-off valve is arranged on the outlet pipe 8. 9. A shell cover 10 is arranged on the top of the shell 7, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap