Linen dyed cloth printing and dyeing process

A printing and dyeing process and flax dyeing technology, applied in the directions of dyeing, singeing, dry cleaning fiber products, etc., can solve problems such as unfavorable popularization and use, and achieve the effect of improving printing and dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

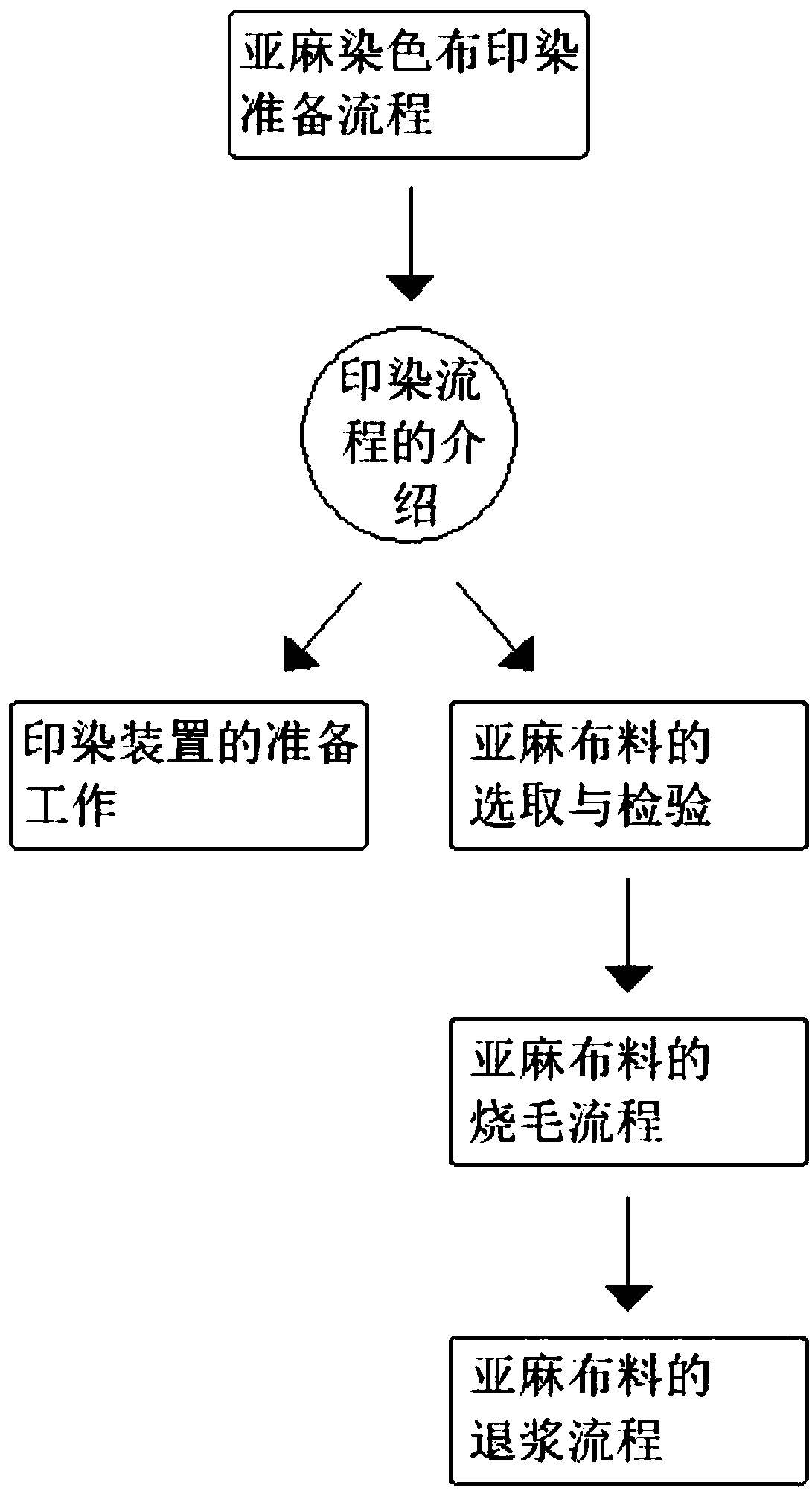

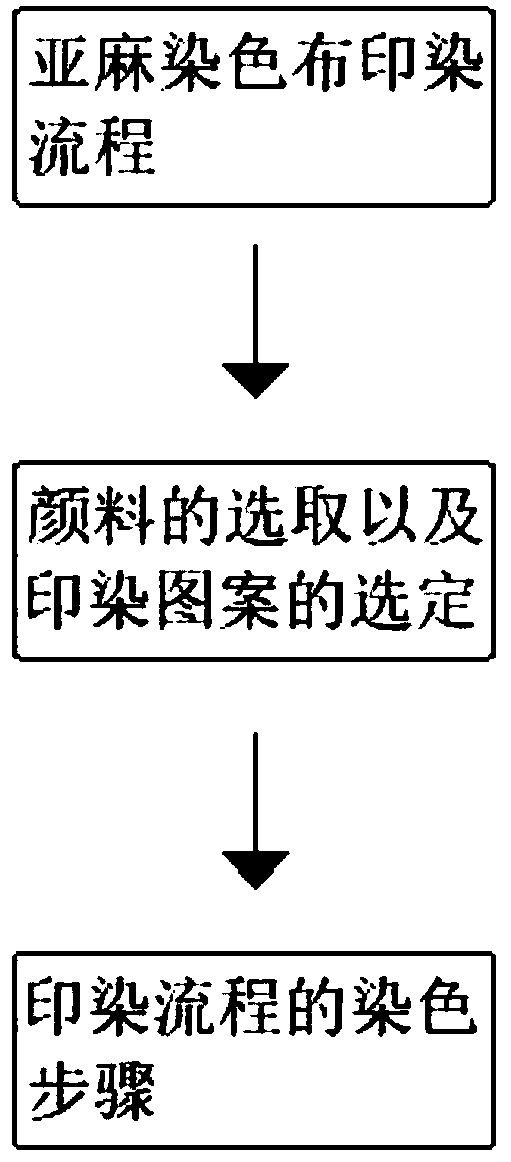

[0027] A printing and dyeing process for linen dyed cloth, characterized in that it comprises the following seven steps:

[0028] Step 1: Introduction of printing and dyeing process;

[0029] Step 2: Preparation of the printing and dyeing device;

[0030] Step 3: Selection and inspection of linen fabrics;

[0031] Step 4: singeing process of linen fabric;

[0032] Step 5: Desizing process of linen fabric;

[0033] Step 6: Selection of printing and dyeing pigments and selection of printing and dyeing patterns;

[0034] Step 7: Dyeing in the printing and dyeing process.

[0035] The introduction of the printing and dyeing process, scouring and bleaching to remove impurities contained in natural fibers, and the addition of various sizing materials, oil agents and contaminated dirt during the textile processing process, the existence of these impurities not only hinders the smooth dyeing and finishing process It also affects the wearing performance of the fabric. The purpose ...

Embodiment 2

[0043] A kind of flax dyed cloth printing and dyeing process that embodiment 1 obtains is illustrated, as follows:

[0044] Linen is woven by twisting linen. The surface is not as smooth as chemical fiber and cotton, but has a vivid concave-convex texture. Painters often use the subtle and interesting material beauty of linen. Besides synthetic fibers, linen is a textile The strongest kind of linen cloth has high fiber strength and is not easy to tear or puncture. It can be scraped and pressed with a palette knife. Clothes will inevitably be stained with dirt and dirty clothes during the process of people wearing them. If it is not changed and washed, it will not only affect the appearance of the clothing, but also affect the elasticity, air permeability, warmth retention and reduce the fastness of the clothing. The decomposition of dirt will produce harmful components and provide conditions for the reproduction of bacteria and microorganisms. Harmful to human health, with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com