Heading machine cutting part and application thereof

A cutting section and roadheader technology, applied in cutting machinery, mining equipment, earth-moving drilling, etc., can solve the problems of increased wear of large-scale picks, decreased life, and inability to fundamentally solve problems, so as to improve rock breaking. Efficiency, improve stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

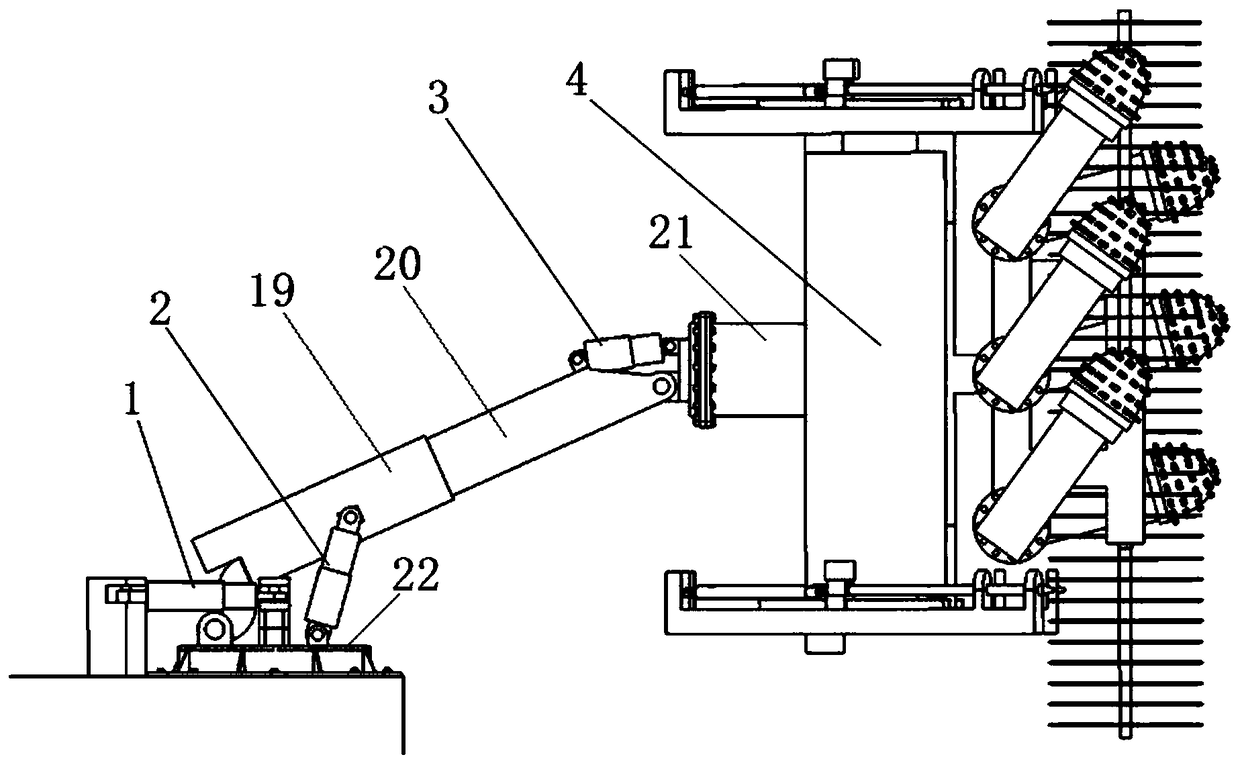

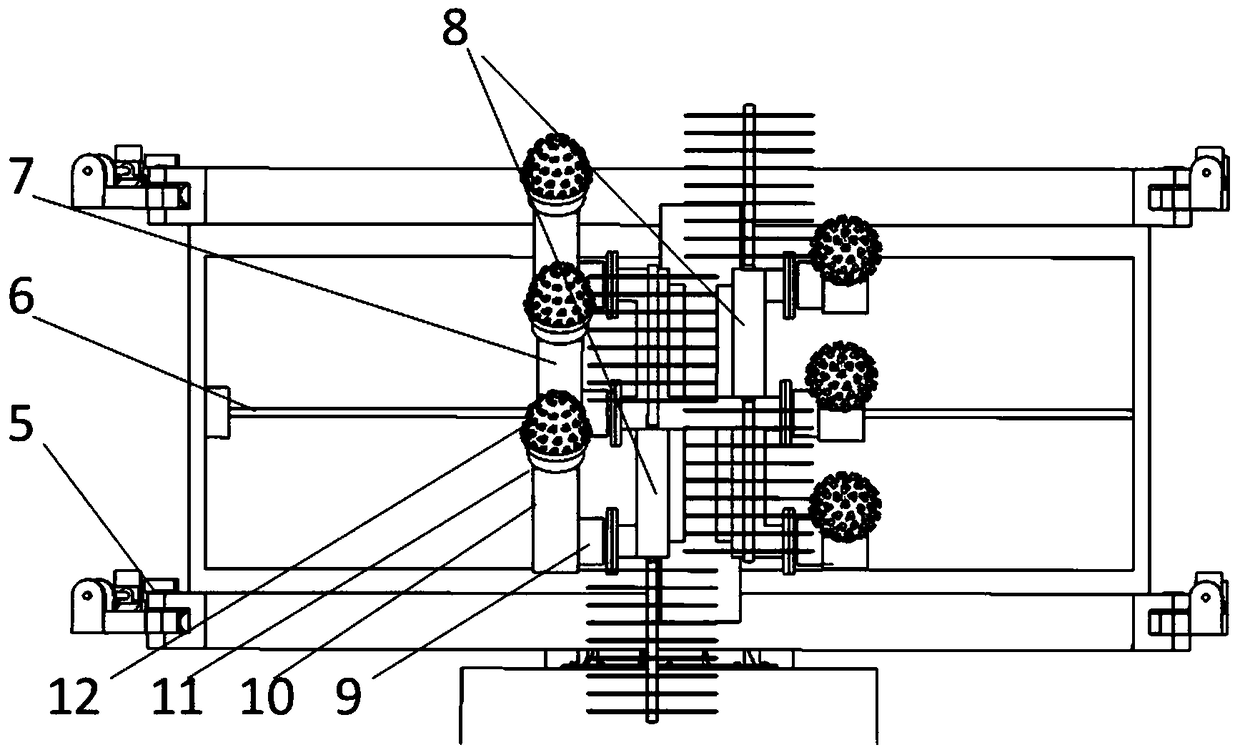

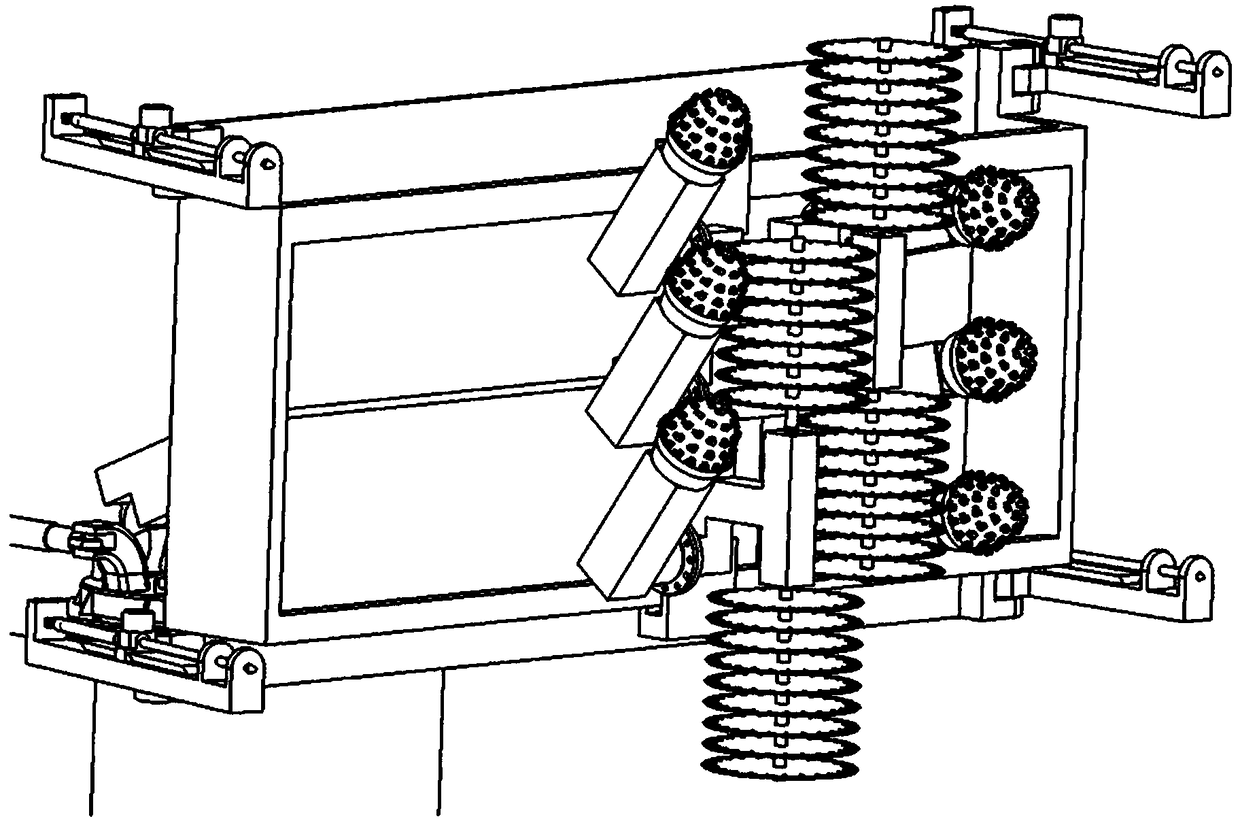

[0034] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a cutting section of a roadheader, which mainly includes a support frame 4, a cutting head cutting group 7 and a diamond saw blade cutting group 8, and the four corners of the support frame 4 are provided with fixing devices. One side of the support frame 4 is provided with a horizontal movement mechanism, and the cutting head cutting group 7 and the diamond saw blade cutting group 8 are arranged on the horizontal movement mechanism.

[0035] In this embodiment, in order to improve the stability of the entire cutting part during operation, four fixing devices 5 are installed at the four corners of the support frame 4 . Specifically, each fixing device 5 includes an angle adjustment oil cylinder 13, a telescopic oil cylinder 14, a guide slider 15, a first hydraulic motor 16, a guide rail 17 and an auger rod 18, and the cylinder barrel of the angle adjustment oil cylinder 13 and the side of the suppor...

Embodiment 2

[0042] Such as figure 1 As shown, this embodiment provides a roadheader, including a rotary platform 22, a rotary cylinder 1, a height adjustment cylinder 2, a first mechanical arm 19, a posture adjustment cylinder 3, a second mechanical arm 20, and a third mechanical arm 21. It also includes the cutting part of the roadheader mentioned above; the tail end of the first mechanical arm 19 is hinged on the rotary platform 22, one end of the rotary cylinder 1 is fixed, the other end is hinged to the rotary platform 22, and the two ends of the height-adjusting cylinder 2 are connected to the rotary platform 22 respectively. 1. The first mechanical arm 19 is hinged, the second mechanical arm 20 is sleeved on the front end of the first mechanical arm 19 and the front end of the second mechanical arm 20 is fixedly connected to the third mechanical arm 21 through a flange, and the third mechanical arm 21 The front end is connected with the support frame 4, and the posture adjustment oi...

Embodiment 3

[0044] A kind of working method of boring machine as described in embodiment 2, comprises the following steps:

[0045] (1) After the roadheader advances to a predetermined position, adjust the left and right positions of the cutting section through the telescopic adjustment of the rotating cylinder 1, adjust the up and down position of the cutting section through the telescopic adjustment of the heightening cylinder 2, and adjust the vertical position of the cutting section through the telescopic adjustment of the second mechanical arm 20. The front and rear positions of the cutting part are adjusted parallel to the working surface through the telescopic adjustment of the posture adjustment cylinder 3;

[0046] (2) Then the first hydraulic motor 16 starts to drive the auger rod 18 to rotate, and the telescopic oil cylinder 14 pushes the guide slider 15 to advance along the guide rail 17, so that the auger rod 18 rotates and drills into the rock wall, thereby fixing the entire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com