Flow scattering integration device for water conservation power generation blades

A technology of integrated devices and power generation blades, which is applied in the directions of hydropower generation, machines/engines, and reaction engines, etc. It can solve the problems of large water flow impact, low utilization rate of water energy into electrical energy, and large resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

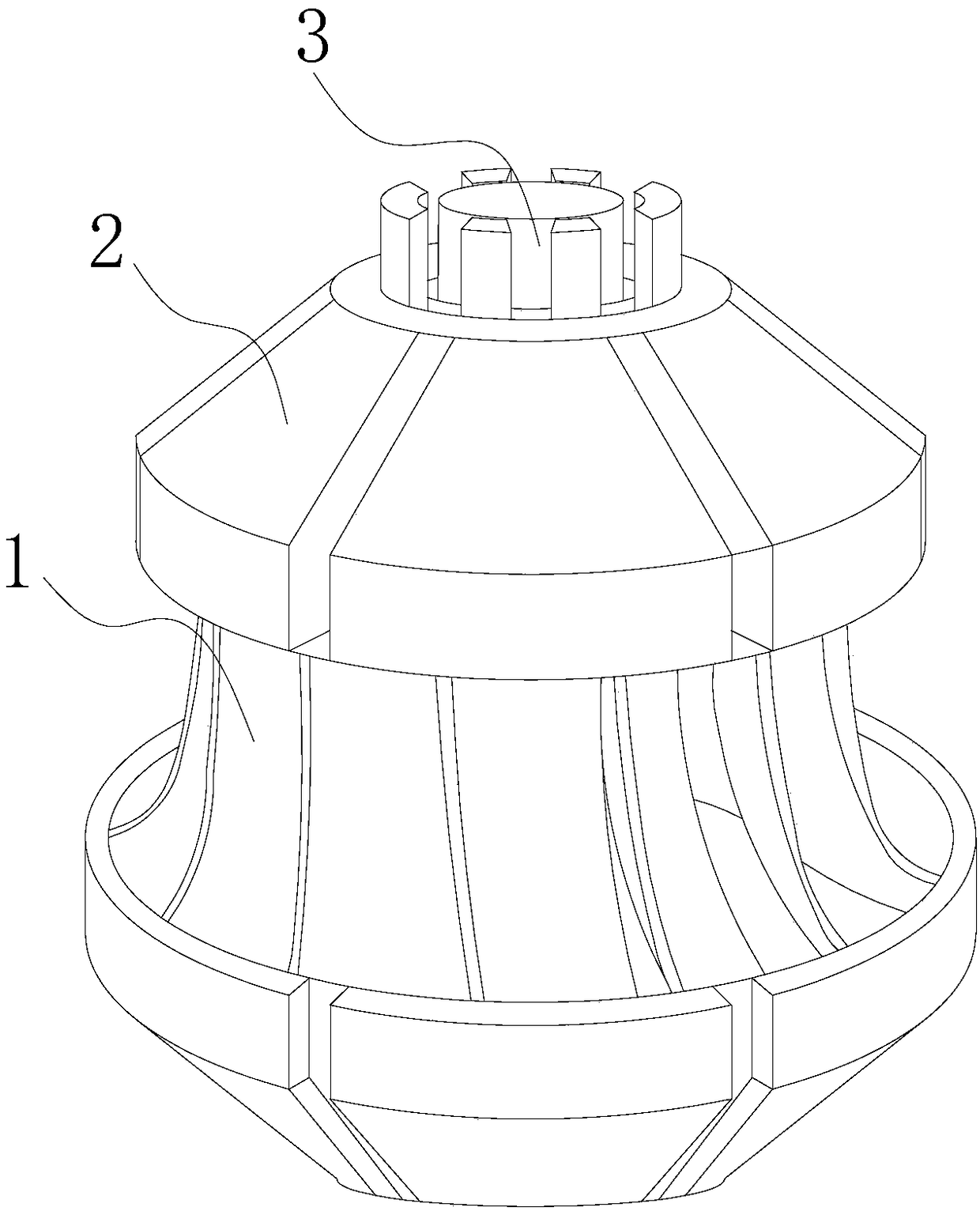

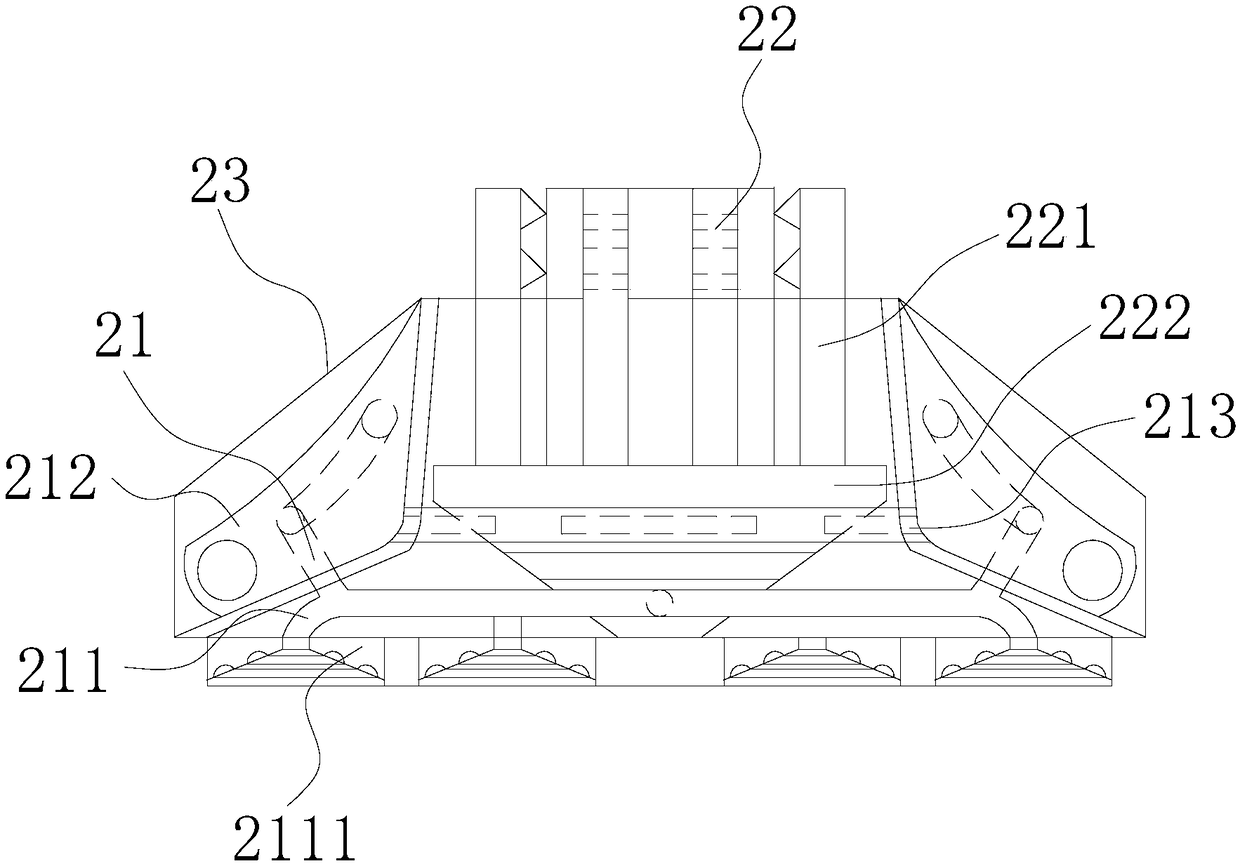

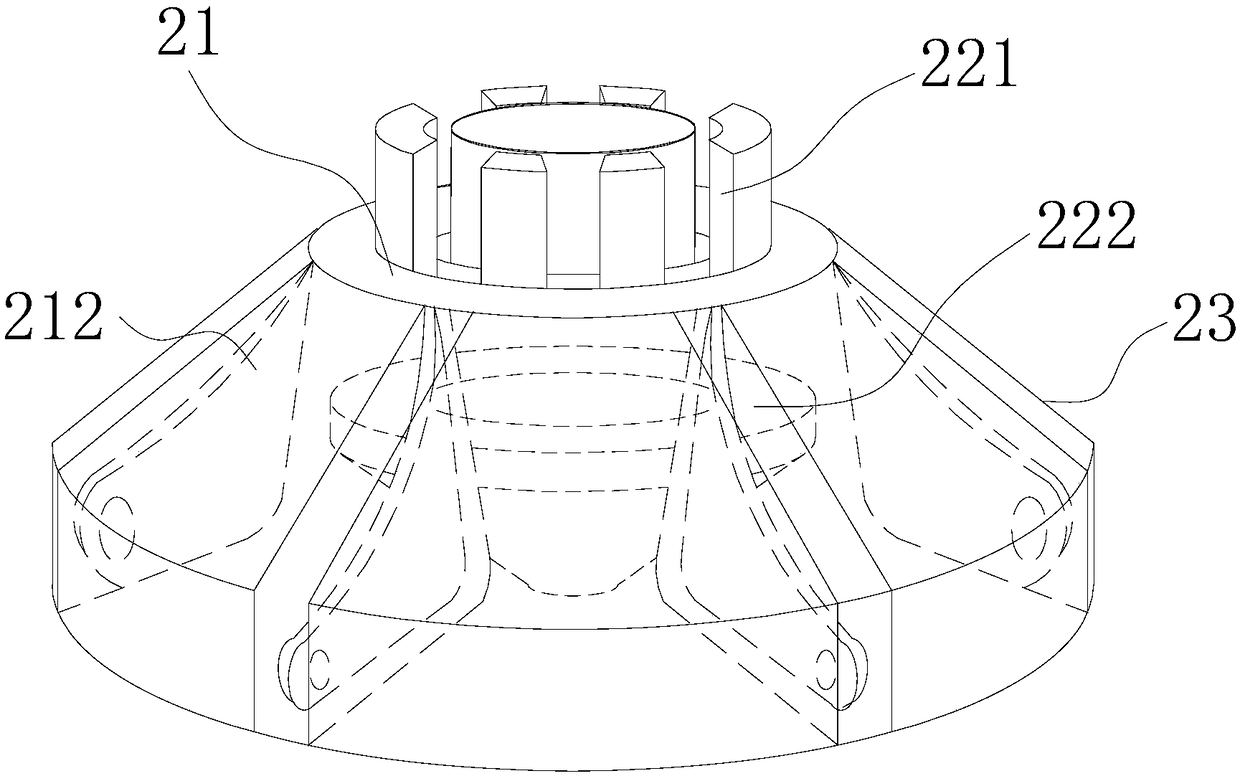

[0020] Such as Figure 1-Figure 6 As shown, the present invention provides a diffuse flow integration device for hydropower generation blades, the structure of which includes a blade 1, a diffuse flow integration device 2, and a large external shaft 3, and the blade 1 is vertically embedded and installed under the diffuse flow integration device 2 position, the external large shaft 3 is vertically installed on the upper end of the diffuse flow integration device 2, the external large shaft 3 is mechanically connected to the blade 1 through the diffuse flow integration device 2, and the diffuse flow integration device 2 includes an expansion mechanism 21, Push-off mechanism 22, casing 23, described expansion mechanism 21 is horizontally installed in the middle position inside casing 23, and described push-off mechanism 22 is vertically installed in the inside of casing 23, and described expansion mechanism 21 and push-off mechanism 22 are carried out mechanically by water flow. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com