Bearing with blade type retainer

A cage and blade type technology, applied in the field of bearings with blade type cage, can solve the problems of poor bearing lubrication and heat dissipation performance, and achieve the effect of good oil guiding effect, speeding up the flow rate and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

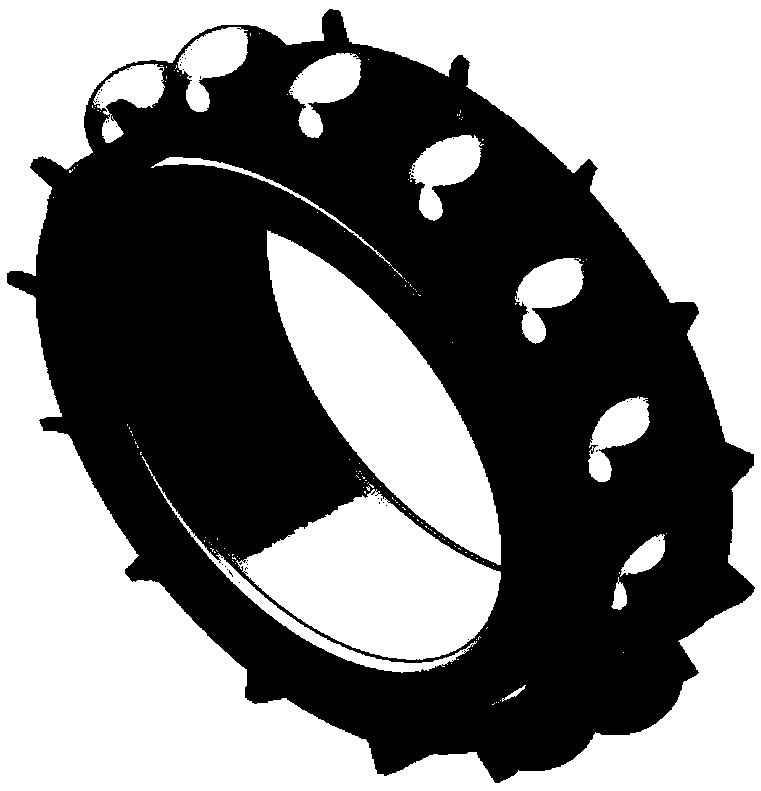

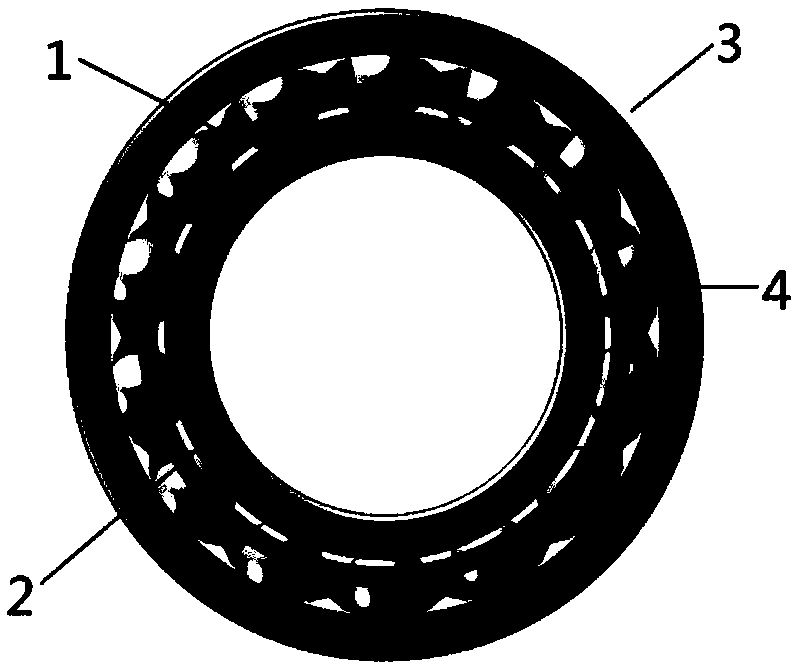

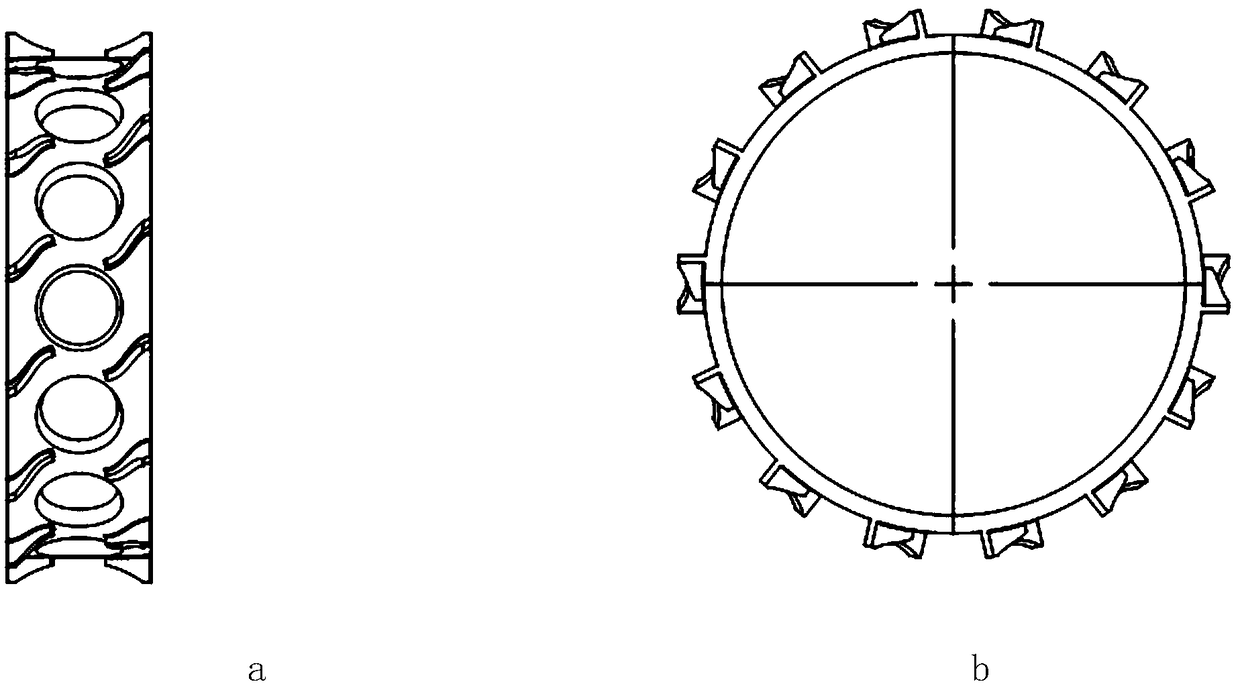

[0026] A bearing with a vane cage, such as figure 1 , figure 2 , image 3 As shown, it includes: cage 1, bearing inner ring 2, bearing outer ring 3 and roller 4. Cage 1, bearing inner ring 2, bearing outer ring 3 and roller 4 are assembled into a bearing;

[0027] The outer surface of the cage 1 has a blade-type boss, which has a certain angle with the bearing axis, and the blade-type boss can play the role of forced oil guide, that is, fluids such as lubricating oil and air are introduced into the bearing In the ring, or between the roller and the cage;

[0028] The blade-type bosses are arranged on the outside of the cage in two rows, arranged in a reverse symmetrical circle, so as to ensure that no matter how the rotation direction of the bearing changes, the fluid can always be forced to enter the inside of the bearing;

[0029] The end of the boss close to the roller needs to keep a gap with the roller to prevent the boss from affecting the movement of the roller and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com