Flow channel switching micro-valve structure for micro-fluidic chip and switching control method thereof

A microfluidic chip, flow channel switching technology, applied in chemical instruments and methods, valve devices, laboratory utensils and other directions, can solve the problems of high production cost, high production difficulty, complex structure design, etc. The switching action is stable and accurate, and the operation is simple and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

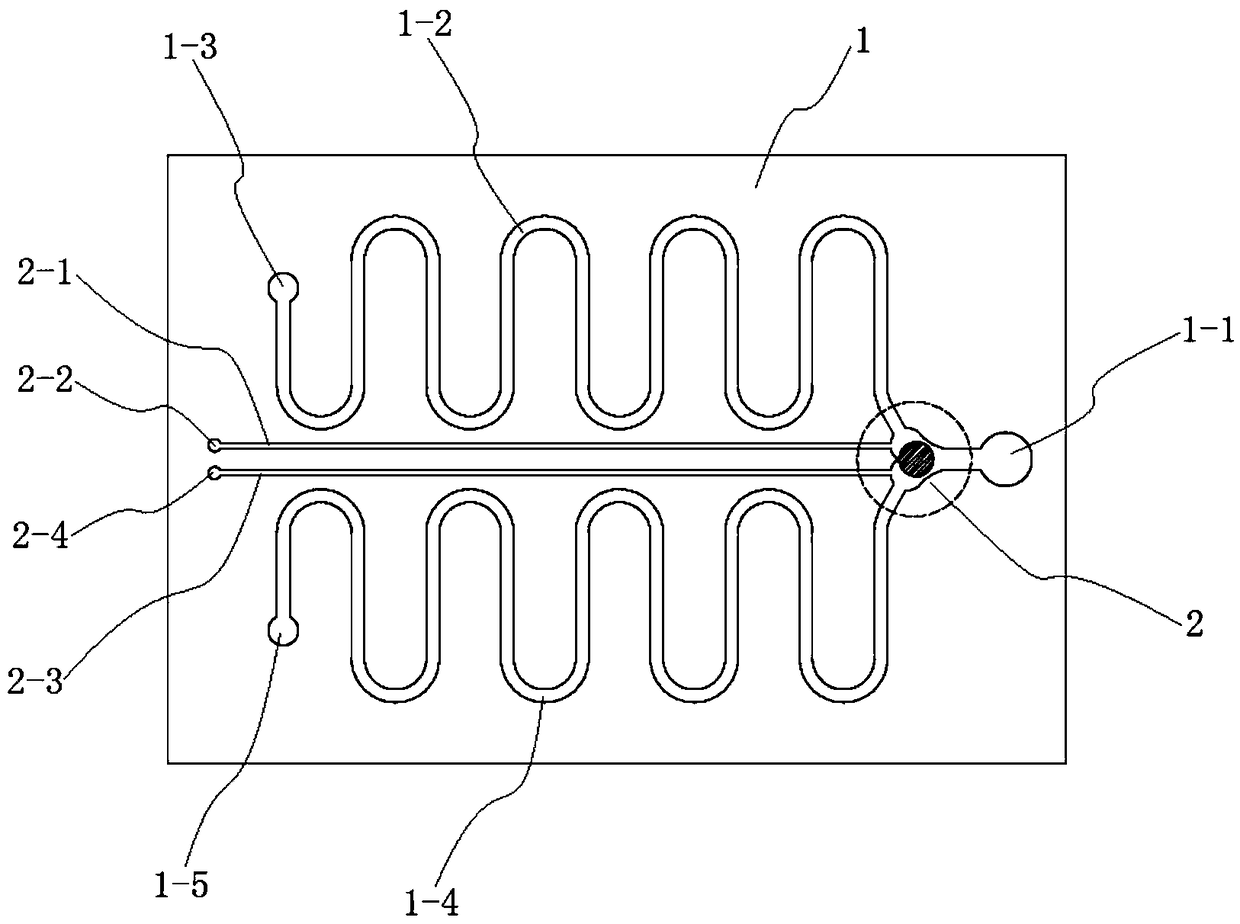

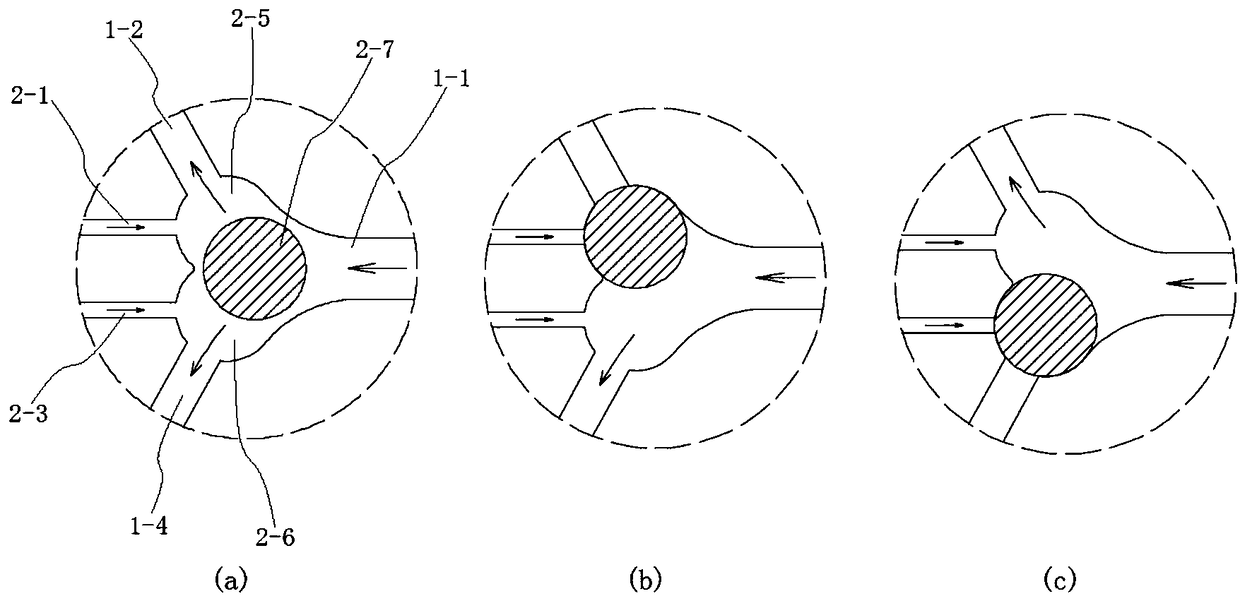

[0034] combine figure 1 and figure 2As shown, a microfluidic chip channel switching microvalve structure in this embodiment includes a microfluidic chip 1 and a switching microvalve 2 disposed in the microfluidic chip 1, and the microfluidic chip 1 has a first channel 1-2 and the second flow channel 1-4, the specific shapes of the first flow channel 1-2 and the second flow channel 1-4 are designed according to the working requirements of the microfluidic chip 1, the first flow channel 1-2 and the The second flow channel 1-4 is connected to the liquid inlet 1-1 on the microfluidic chip 1 through the switching microvalve 2, and the end of the first flow channel 1-2 is provided with a first liquid outlet 1-3, and the second flow channel The end of 1-4 is provided with a second liquid outlet 1-5, and the liquid enters through the liquid inlet 1-1, and the switching microvalve 2 is used to select one of the first flow channel 1-2 and the second flow channel 1-4 In the flow chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com