Grooved heat pipe with circumferential grooves and connection method of grooved heat pipe

A technology of grooved heat pipes and circumferential grooves, which is applied in the field of phase change heat transfer, can solve the problems of low heat transfer efficiency, achieve the effects of improving heat transfer effect, reducing thickness, and avoiding height increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

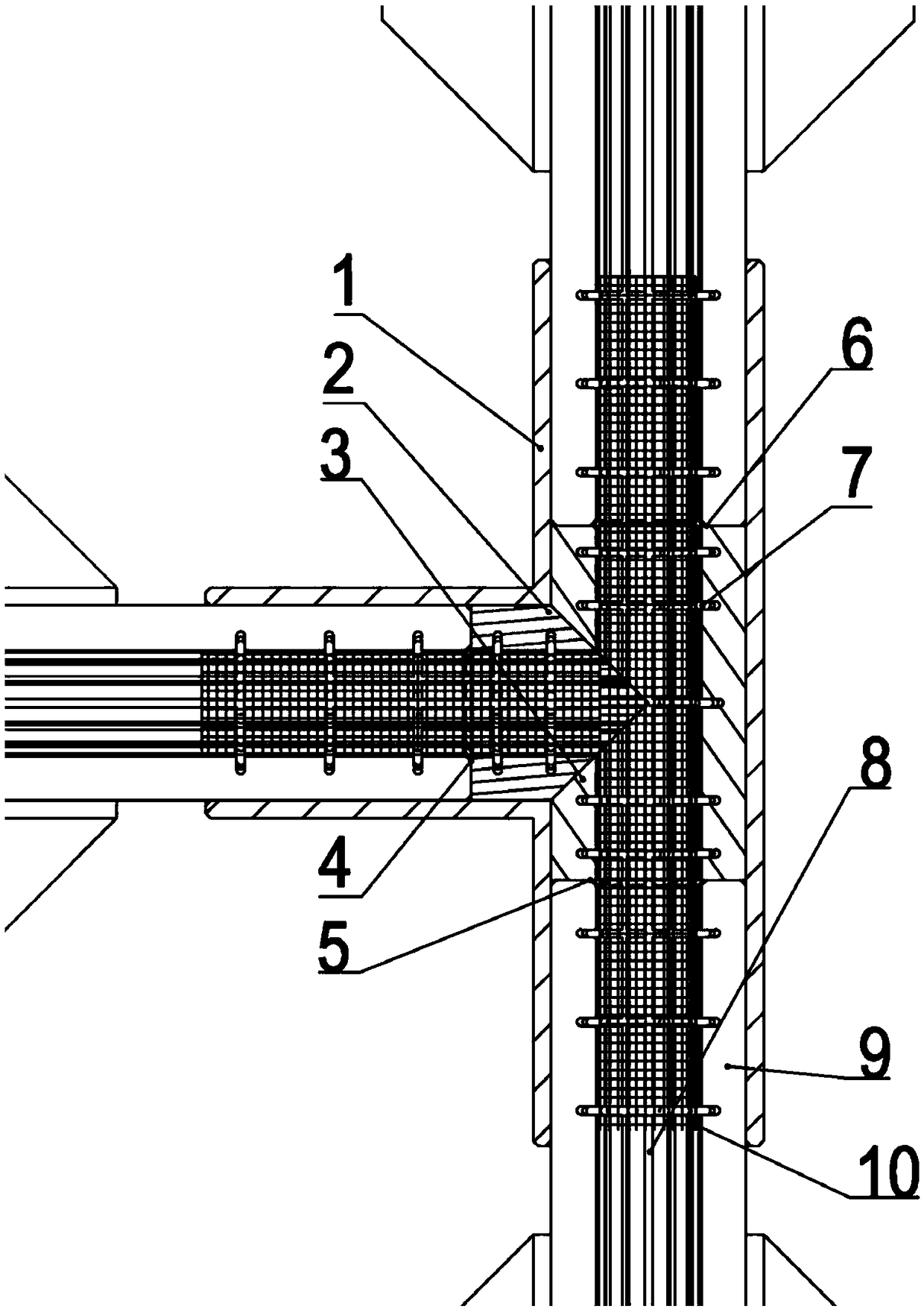

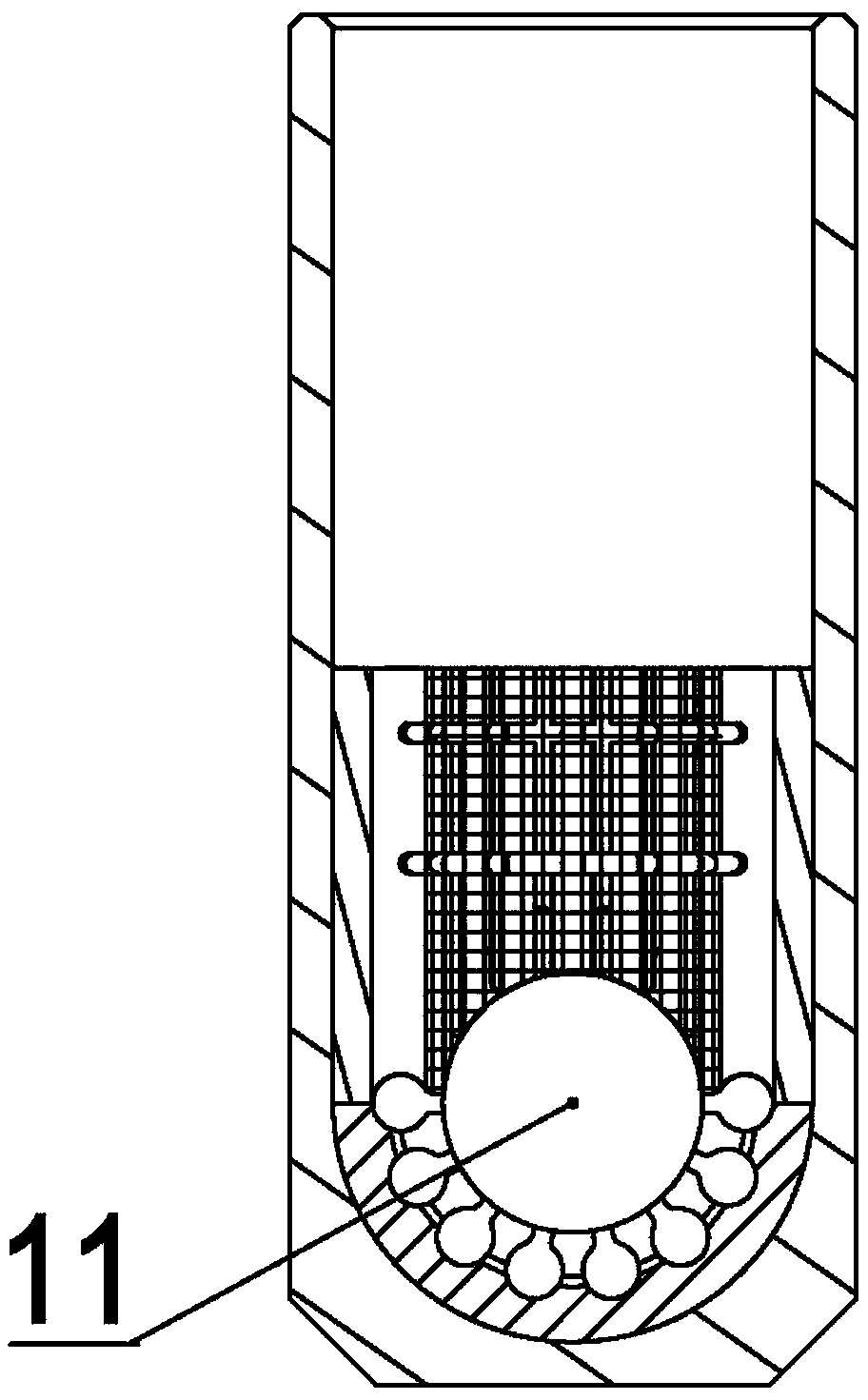

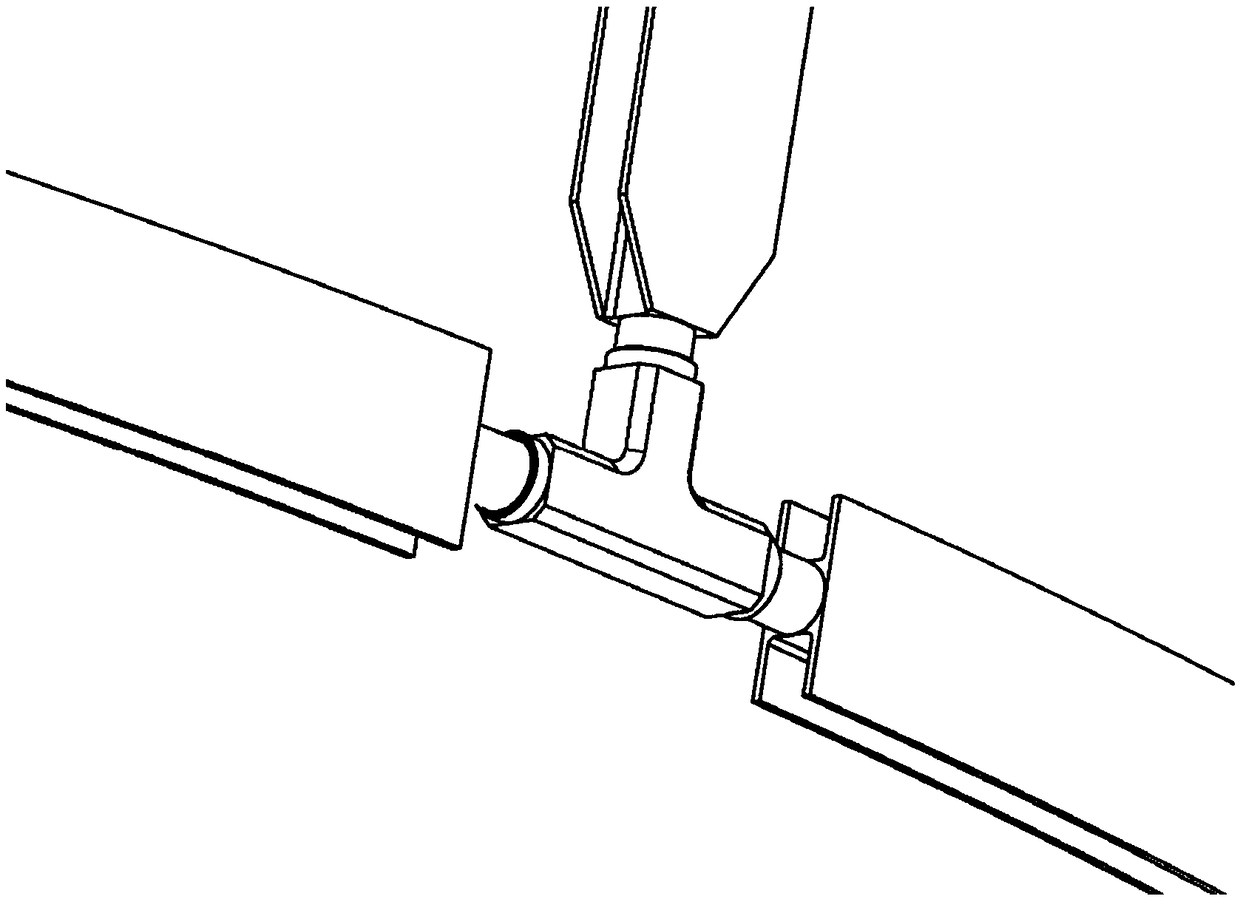

[0045] The invention relates to the field of phase change heat transfer technology, and discloses an axial channel heat pipe with circumferential grooves and a connection method thereof. A special-shaped groove heat pipe system in which the inner axial groove and the steam channel are connected to each other. Axial channel heat pipe shell is provided with a plurality of circumferential channels arranged in parallel at the port connected to the uniform temperature joint, and the plane where each circumferential channel is located is the same as the axial channel in the axial channel shell. The plane on which it is located is orthogonal, and each circumferential groove is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com