Vacuum device for tightness detection of 45 degree fillet weld at CM node of LNG ship

A technology of LNG ships and vacuum devices, applied in measuring devices, using liquid/vacuum degree for liquid tightness measurement, and detecting the appearance of fluid at the leak point, etc., can solve the problems such as the inability to detect the tightness of 45° welds, Achieve the effect of simple structure, improving detection efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

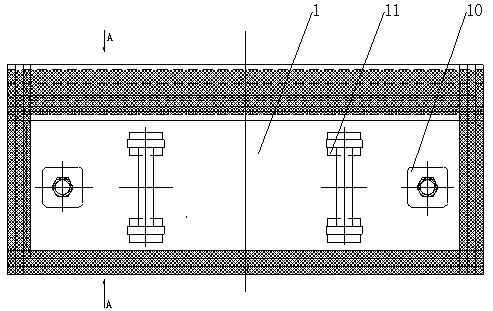

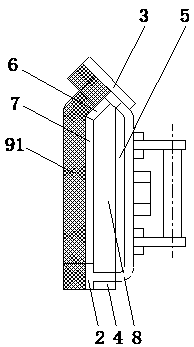

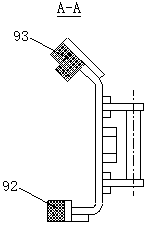

[0021] The vacuum device for detecting the tightness of the 45° fillet weld at the CM node in the LNG ship construction of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments, in order to understand its structure type and usage more clearly. , but it cannot be used to limit the protection scope of the present invention.

[0022] As a special construction device, the present invention is applied at the CM node on the LNG ship, where the 45° fillet weld at the CM node is formed by welding the end surface of the platform plate and the contact position of the inclined side plate, and the end surface of the platform plate and the inclined side plate The inner side angle of the contact position of the surface is 135°, and the edge of the inclined side plate surface is welded on the inner side of the platform plate end surface near the edge to form a 45° angle seam, leaving a gap between the weld seam and the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com