AC-DC chip and high-voltage free-wheel diode integrated chip structure and power module group

A technology of freewheeling diodes and integrated chips, which is applied in circuits, electrical components, and electric solid-state devices, can solve the problems of power drive module volume, unfavorable use, etc., reduce volume costs, improve production efficiency, and overcome technical barriers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

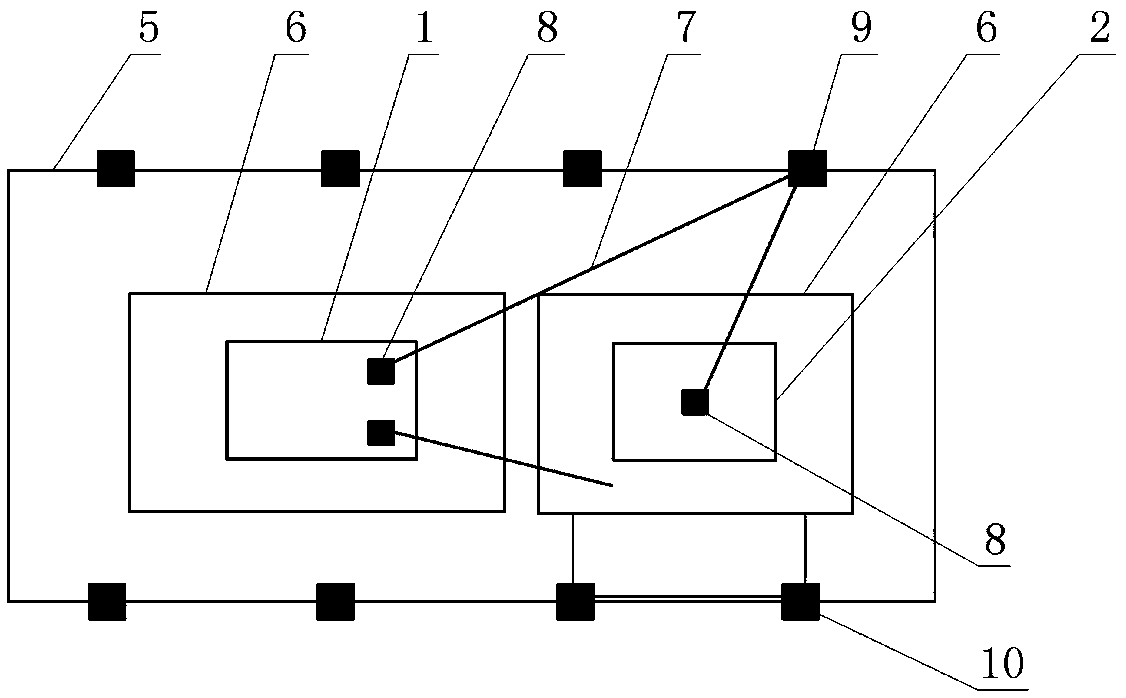

Embodiment 1

[0024] Such as figure 1 As shown, in this embodiment, the first chip 1 is provided with an integrated structure, that is, the first chip 1 adopts an AC-DC chip including a control logic circuit and a power MOS device, wherein the first chip 1 and the second chip 2 They are respectively arranged on two independent lead frames. The first chip 1 is arranged on the lead frame where it is located through insulating glue, and the anode of the second chip 2 is connected to the lead frame where it is located through conductive glue or solder paste. On the first chip 1 The other pad 8 leads out the drain of the power MOS device in the first chip 1 through the metal lead 7, and is connected to the lead frame where the second chip 2 is located to form a connection with the anode of the second chip 2.

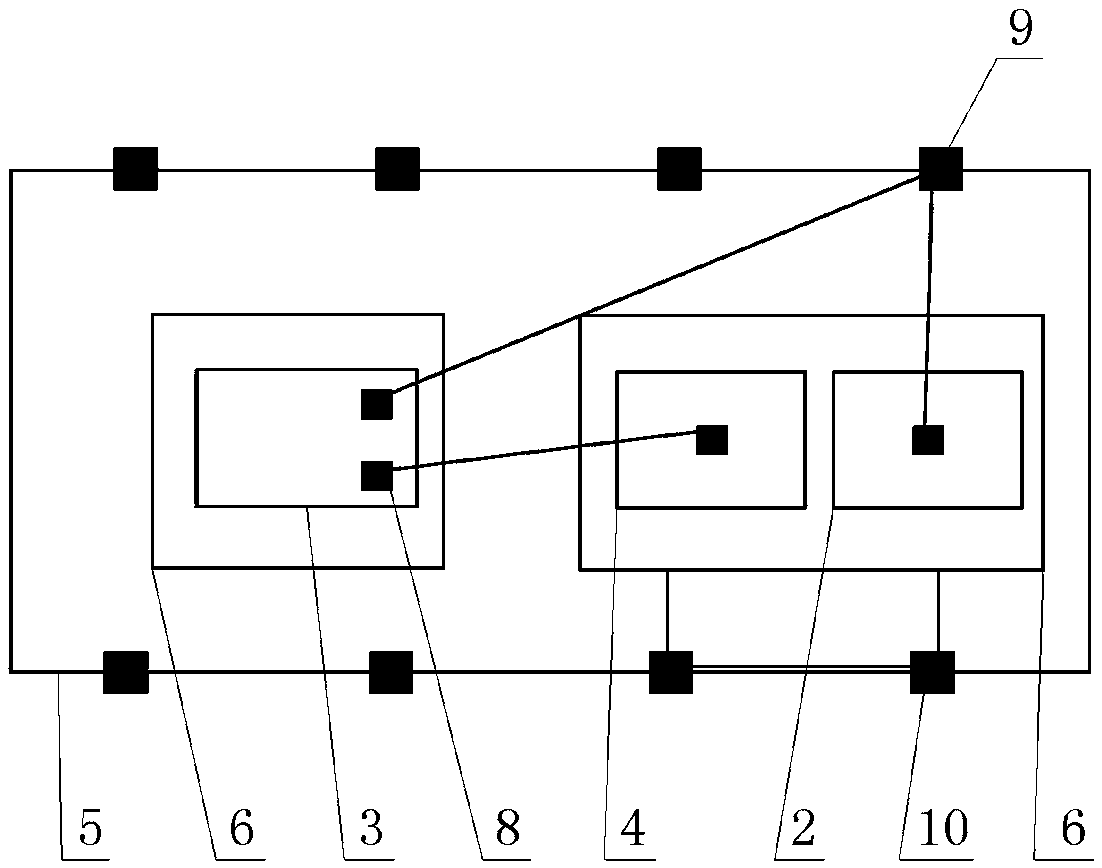

Embodiment 2

[0026] Such as figure 2As shown, in this embodiment, the first chip 1 is set as a split structure, that is, the first chip 1 includes a third chip 3 including a control logic circuit in AC-DC and a fourth chip 3 including a separate power MOS device. Chip 4. Wherein, the third chip 3 and the fourth chip 4 are respectively arranged on two independent lead frames, the third chip 3 is provided with at least two bonding pads 8, and one bonding pad 8 on the third chip 3 passes through the metal The lead 7 is connected to the high-voltage power supply pin 9 of the plastic package 5, another pad 8 on the third chip 3 is connected to the gate of the fourth chip 4 through the metal lead 7, and the drain of the fourth chip 4 is connected to the gate of the second chip 2. anode. In this embodiment, the fourth chip 4 and the second chip 2 are jointly arranged on the same lead frame, and the drain of the fourth chip 4 and the anode of the second chip 2 are connected to the lead frame th...

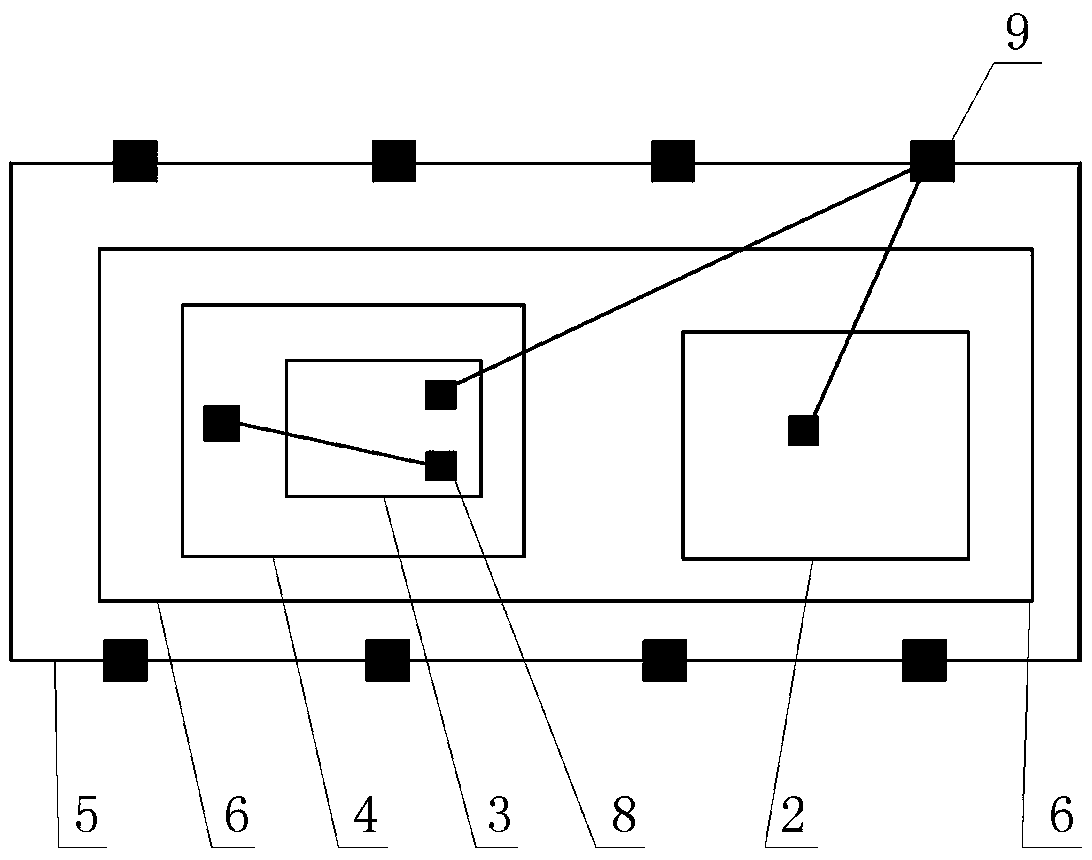

Embodiment 3

[0029] Such as image 3 As shown, in this embodiment, the first chip 1 is set as a split structure, that is, the first chip 1 includes a third chip 3 including a control logic circuit in AC-DC and a fourth chip 3 including a separate power MOS device. Chip 4. Wherein, the fourth chip 4 and the second chip 2 are jointly arranged on the same lead frame through conductive glue or solder paste, and the drain electrode of the fourth chip 4 and the anode of the second chip 2 are connected to the lead wire through conductive glue or solder paste. frame, the third chip 3 is arranged on the gate surface of the fourth chip 4 through insulating glue, at least two pads 8 are arranged on the third chip 3, and one pad 8 on the third chip 3 passes through a metal lead 7 Connect the high-voltage power supply pin 9 of the plastic package 5, another pad 8 of the third chip 3 is connected to the gate of the fourth chip 4 through the metal lead 7, and the lead frame protrudes from the plastic pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com