Fixed and integrated elastic height-limitation frame transverse beam material taking basalt fibers as framework

The technology of basalt fiber and basalt fiber cloth is applied in the field of materials used for fixing integral elastic limiting overhead beams, which can solve the problems of high hardness of overhead limiting beams, and achieve the effect of ensuring strength and improving elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The technical scheme adopted by the present invention is: the material for the fixed integral elastic limit-elevation beam with basalt fiber as the skeleton comprises the following steps: (1) first mix the vulcanizing agent and the vulcanization accelerator together with styrene-butadiene rubber powder and then put them into 120 (2) Immerse the basalt fiber cloth into the mortar made of 34 parts of compounding agent, wherein the compounding agent components are styrene-butadiene rubber powder, p-benzoquinone dioxime, 2, 2'- Dithiodibenzothiazole, No. 120 gasoline, and carbon black are in a mass ratio of 10:2:1:20:1, then dried in the shade, and finally solidified to obtain a limited-elevation beam material.

Embodiment 2

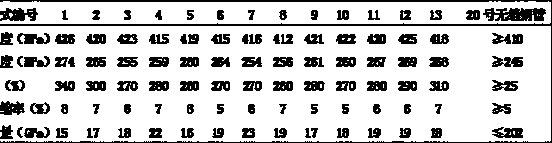

[0017] The processing method of embodiment 2 to embodiment 13 is identical with embodiment 1, and raw material composition is as follows respectively:

Embodiment 2

[0019] Change the number of parts of the vulcanization system, and keep the number of other compounding agents unchanged so that the number of parts of the overall compounding agent is 36 parts; the main components of the glue are styrene-butadiene rubber powder, p-benzoquinone dioxime, 2,2'-disulfide Substituted dibenzothiazole, No. 120 gasoline, and carbon black in a mass ratio of 10:3:2:20:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com