Method for vitrification of arsenic and antimony

A vitrification and glass technology, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve the problems of expensive formation of scorodite, elaborate and complicated landfill procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present application is further illustrated by the following non-limiting examples.

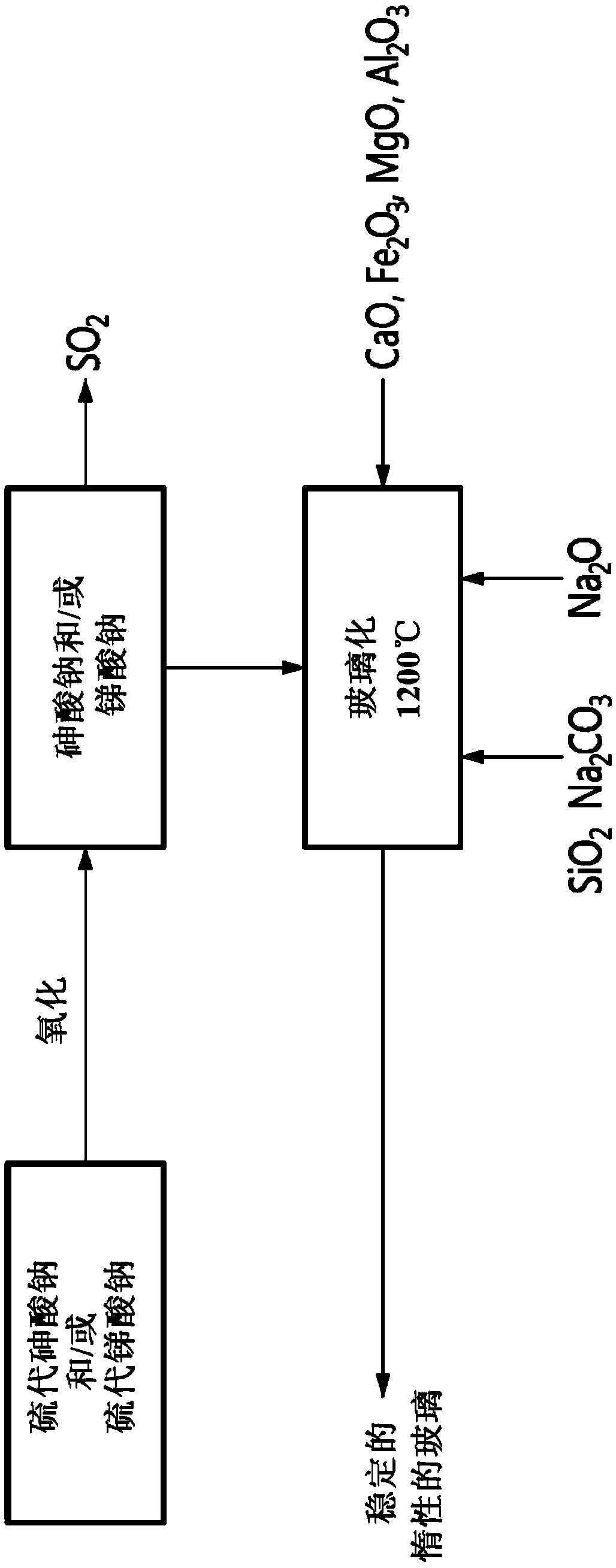

[0013] figure 1 The flowchart of FIG. 1 describes a method according to an embodiment of an aspect of the present invention.

[0014] When using sodium sulfide Na 2 When S is alkaline dissolved and crystallized, arsenic and antimony are respectively converted into thioates, that is, thioarsenate (Na 3 AsS 4 ) or thioantimonate (Na 3 Sb 4 ) form exists.

[0015] The oxidation of these thiosalts is at a temperature range of about 200°C to 400°C, using air or oxygen, replacing the sulfur on the arsenic and antimony with oxygen, simultaneously producing sulfur dioxide SO 2 , as shown by the following relation:

[0016] Na 3 AsS 4 +6O 2 →Na 3 AsO 4 +4SO 2 (1)

[0017] Na 3 Sb 4 +6O 2 →Na 3 SbO 4 +4SO 2 (2)

[0018] The resulting sodium arsenate (Na 3 AsO 4 ) and sodium antimonate (Na 3 SbO 4 ) are separately incorporated into the glass-forming mixture. The glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com