Carbon nanotube dispersion with improved workability and preparation method therefor

一种碳纳米管、分散体的技术,应用在碳纳米管、纳米碳、化学仪器和方法等方向,能够解决除去麻烦等问题,达到改善分散性、抑制粘度的增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] The method of dispersing the carbon nanotubes prepared by the preparation method according to the present invention in the liquid dispersion medium may be any method and is not particularly limited.

[0076] The carbon nanotube dispersion prepared by the method according to the present invention can be effectively used in the manufacture of electrodes of electrochemical storage devices such as secondary batteries, fuel cells or supercapacitors, electromagnetic wave shielding materials, field emission displays or gas sensors.

[0077] Hereinafter, embodiments of the present invention will be described in detail so that those skilled in the art can easily implement the present invention. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein.

[0078] Physical properties in Examples were measured as follows, and all physical properties were measured at ambient temperature.

[0079] -Bulk de...

Embodiment 1

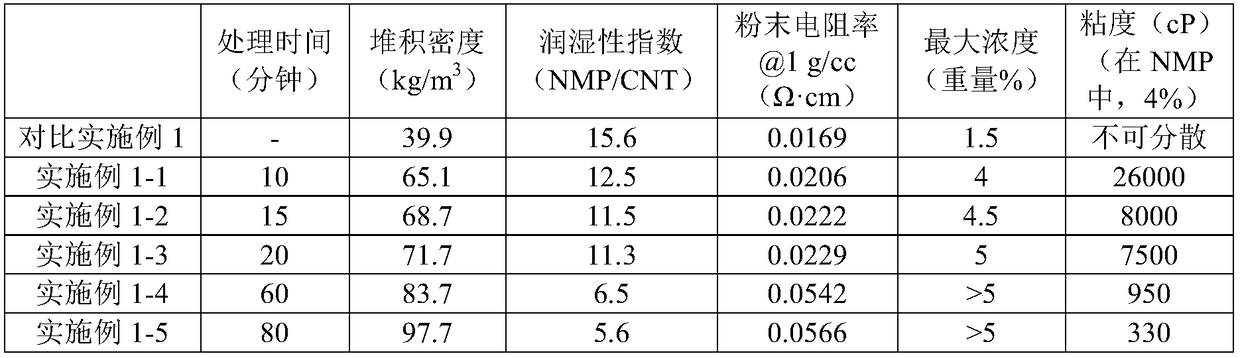

[0090] will have about 40kg / m 3 Bulk density, 185m 2 Stranded carbon nanotubes with a BET specific surface area of / g and an average length of 30 μm were ground at a speed of 500 rpm in a mill (KMtech, KMA-3) containing zirconia balls with a diameter of 2 mm 10, 15, 20, 60 and 80 minutes. Then, the bulk density, wettability index and powder resistivity were measured, the results of which are shown in Table 1. Pulverized carbon nanotubes have a length of 0.2 to 10 μm and a length of 200 to 280 m 2 / g of BET specific surface area.

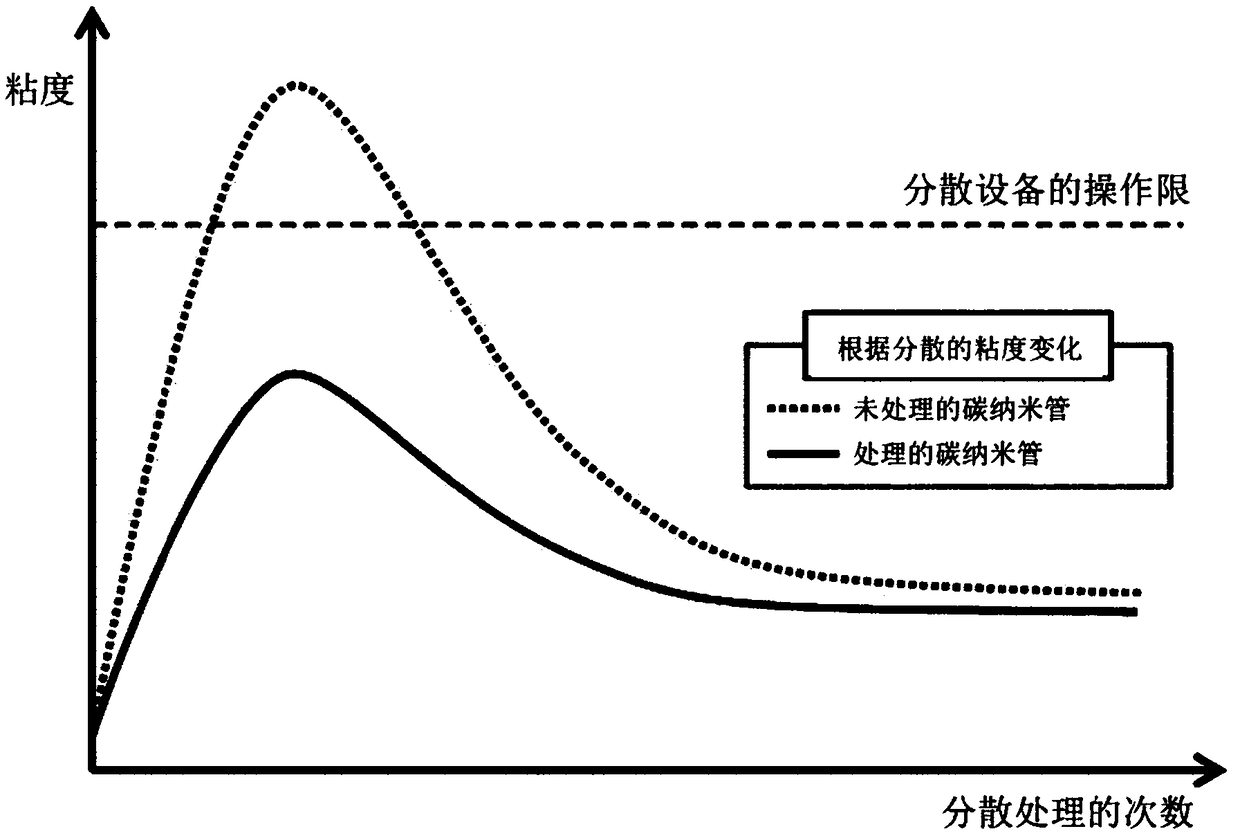

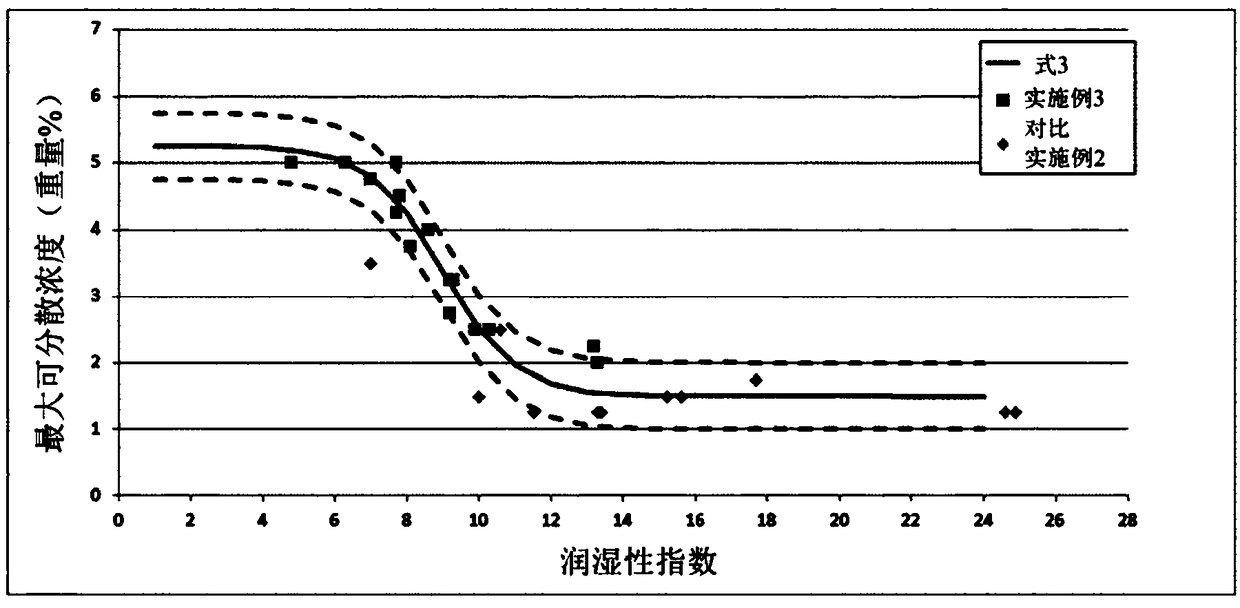

[0091] In addition, the viscosity and the maximum concentration dispersible in NMP were measured. The maximum concentration is defined as the highest concentration in the concentration of the solution that can operate the dispersing equipment (GEA niro soavi (GEA niro soavi) company, PandaPLUS 2000) when using the same dispersant and equipment, wherein Concentrations are weight percent of carbon nanotubes based on the total weight of the dispe...

Embodiment 2

[0095] will have about 40kg / m 3 Bulk density, 185m 2 Strand carbon nanotubes with a BET specific surface area per gram and a length of 30 μm were milled at a speed of 300 rpm for 60, 80, 100 and 140 minutes in a mill containing zirconia balls with diameters of 3 mm and 5 mm. Then, the bulk density, wettability index and powder resistivity were measured, and the results are shown in Table 2. Pulverized carbon nanotubes have a length of 0.2 to 10 μm and a length of 260 to 280 m 2 / g of BET specific surface area.

[0096] In addition, the viscosity and the maximum concentration dispersible in NMP were measured. The maximum concentration is the weight percent of carbon nanotubes based on the total weight of the dispersion.

[0097] [Table 2]

[0098]

PUM

| Property | Measurement | Unit |

|---|---|---|

| apparent density of powders | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com