Process for adapting an estimate of a combustion rate of the soot of a thermal engine particulate filter

A heat engine and particle filter technology, applied to engine components, combustion engines, machines/engines, etc., can solve the problems of reduced engine lubrication effect and increased fuel consumption, and achieve the effect of optimized estimation and correct degradation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

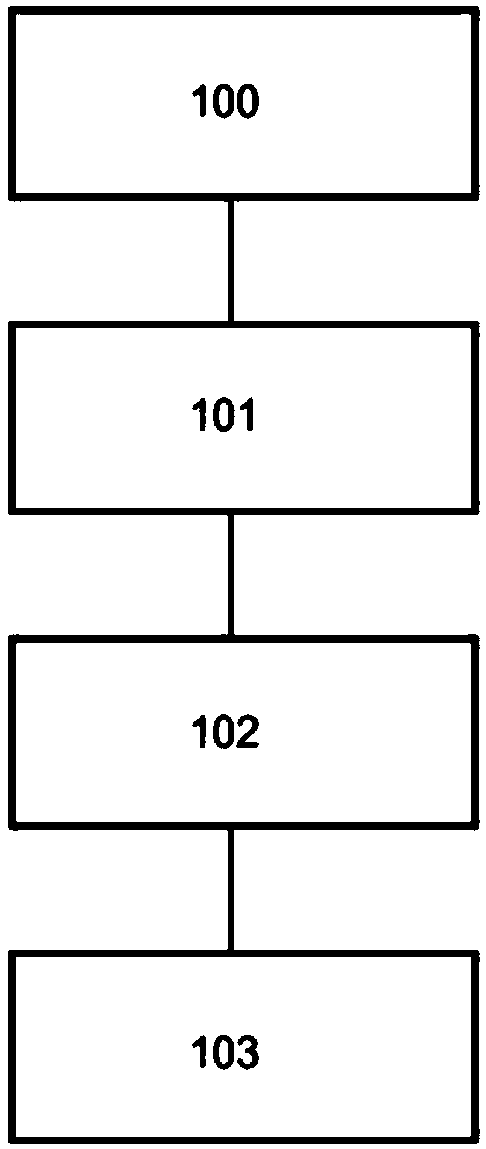

[0033] figure 1 A method for adjusting the soot burning rate of a particle filter in the exhaust line of a heat engine, in particular a motor vehicle, is shown A diagram of the steps of the estimation method.

[0034] During step 100 of particulate filter regeneration, the engine computer estimates the soot burn rate in step 101 based on a standard estimation model known as the Arrhenius model

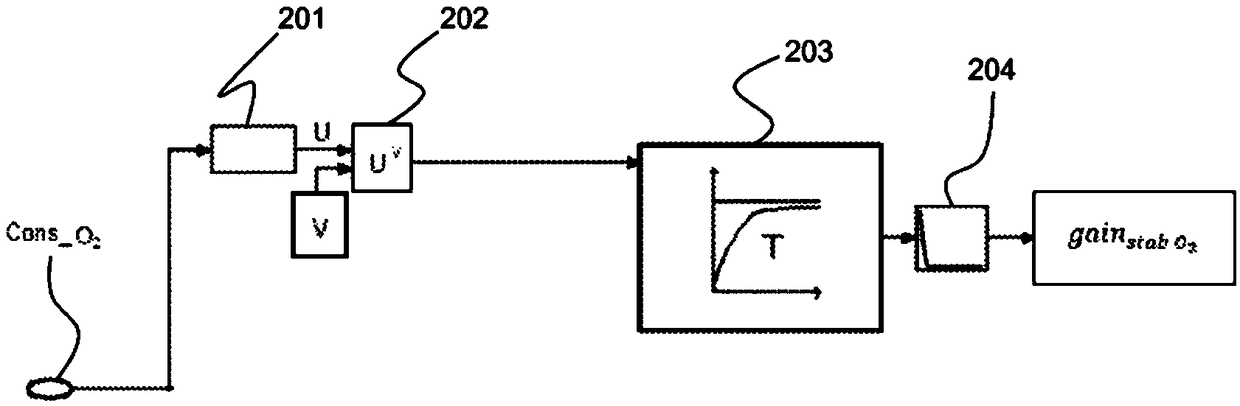

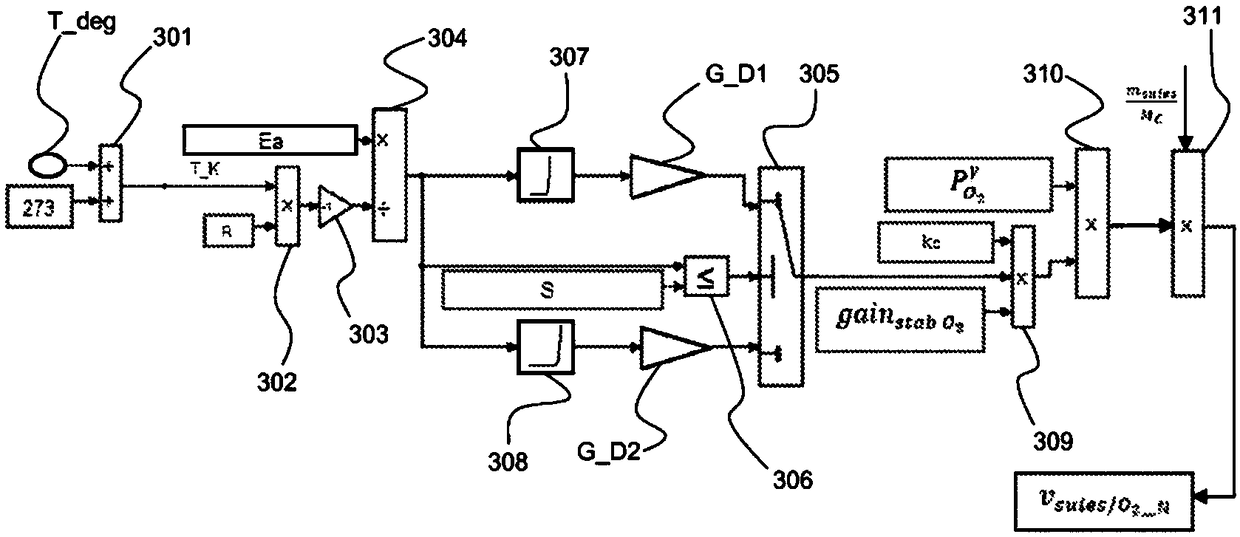

[0035] In step 102, the stable oxygen concentration Cons_0 in the exhaust gas is detected by the filter 2 After that, in step 103, by gain burning rate of soot Weighting is performed to modify the standard estimation model. In other words, by gaining The Arrhenius estimation model is weighted to obtain a modified model for calculating the soot burn rate as follows:

[0036]

[0037] in:

[0038] - is the soot combustion rate by oxygen combustion taking into account the excess combustion of soot during the oxygen stabilization phase;

[0039] - is the soot burning r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com